Pure electric vehicle motor bearing long-life friction-reducing and energy-saving lubricating grease and preparation method thereof

A pure electric vehicle, motor bearing technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem that there is no research report on the special grease for pure electric vehicle motor bearings, the minimum operating temperature can only reach -20 ℃ or more, and the Found problems such as research on long-life energy-saving grease, and achieved the effect of reducing friction coefficient, reducing friction coefficient, and reducing use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

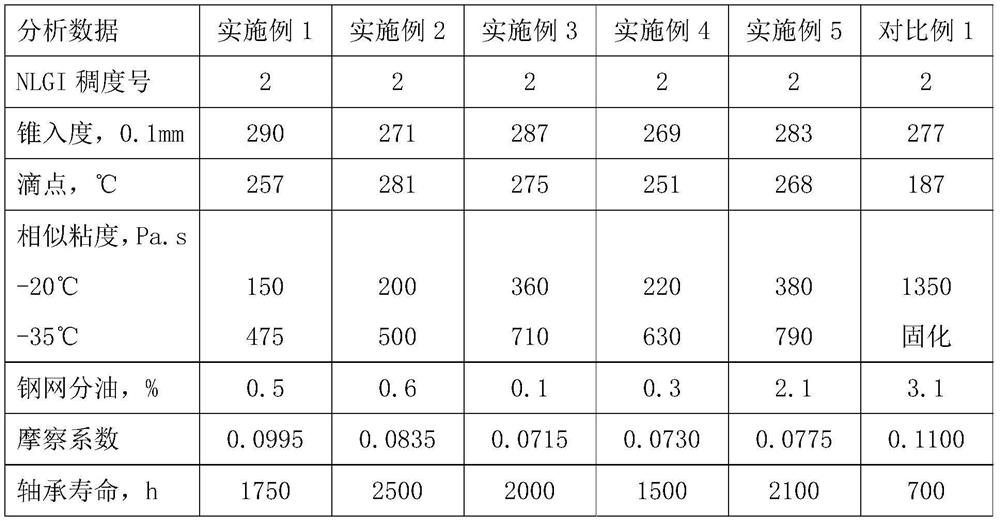

Examples

Embodiment 1

[0037] Add 1660kg of ester synthetic base oil (isotridecyl trimellitate), 160kg of lithium 12-hydroxystearate, 60kg of polyurea powder and 40kg of polytetrafluoroethylene powder into the reactor, stir and heat up to 160-180 ℃, add 62 kg of methyl metaborate, expand at constant temperature for 2-3 hours, then add 10 kg of T531 antioxidant, 6 kg of N-oleoyl sarcosine octadecylamine salt and 2 kg of benzotriazole, and stir to dissolve.

[0038] Transfer the materials into a blending kettle, stir and cool to below 100°C, and shear in circulation for 1.5 hours, then use a high-pressure homogenizer to homogenize and degas to obtain the finished product.

Embodiment 2-5

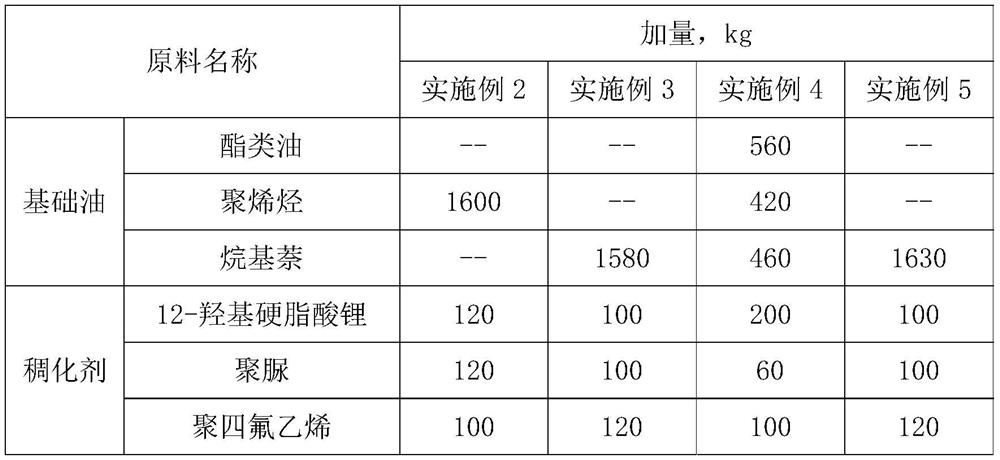

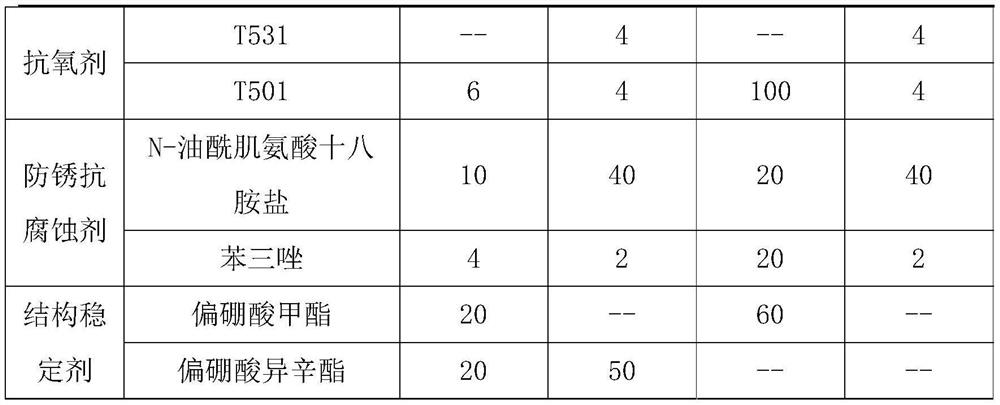

[0040] The production operation process of embodiment 2-5 is identical with embodiment 1, just base oil, ternary compound thickener, antioxidant, anti-rust anti-corrosion agent, the kind and the addition of structural stabilizer are not used, embodiment 2-5 The formulation composition is shown in Table 1.

[0041] Table 1 embodiment 2-5 formula composition

[0042]

[0043]

[0044] The ester oil is pentaerythritol C 8 -C 10 For the mixing of fatty acid esters, the mixing mass ratio is 5:5:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com