Solvent-free silica nanofluid and application thereof

A silicon dioxide and fluid-like technology, which is applied in additives, petroleum industry, lubricating compositions, etc., can solve the problems that there are no public reports on ceramic nanoparticle-like fluid lubricants and lubricating oil additives, so as to improve processing and application performance, improve The effect of bearing capacity, good wear reduction and antiwear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

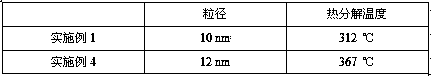

Embodiment 1

[0032] 1) Weigh 10g of 30 wt% silica nanoparticle aqueous solution, disperse it in 40 mL of deionized water, sonicate for 30 minutes, adjust the pH of the solution to 9 with 2 mol / L sodium hydroxide, add 10.0 g of 50 wt% 3- The aqueous solution of (trihydroxysilyl)propylmethylphosphonic acid monosodium salt was heated and stirred at 100° C. for 24 hours, washed and purified to obtain phosphonate-modified silica nanoparticles. It was dispersed in tetrahydrofuran solution, 40 mL of concentrated hydrochloric acid was added, the reaction was stirred at room temperature for 2 hours, the sodium chloride salt was removed by centrifugation, and the product was washed and evaporated to dryness to obtain phosphonic acid-modified silica nanoparticles. The phosphonic acid-modified silica nanoparticles were dissolved in deionized water, 30 g of 70 wt% M2070 aqueous solution was added, and the organic-modified silica nano-based fluid was obtained after heating and stirring at 100 °C for 24 h...

Embodiment 2

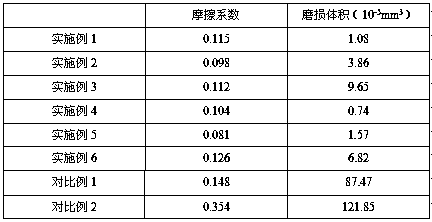

[0035] The silica nano-based fluid containing phosphonic acid functional groups obtained in Example 1 was used as the additive of the base oil polyethylene glycol PEG (Mw~400), the addition amount was 5 wt%, and the lubricant was obtained by ultrasonic dispersion and dissolution to investigate its friction. academic performance.

Embodiment 3

[0037] The silica nano-based fluid containing phosphonic acid functional groups obtained in Example 1 was used as the additive of the base oil polyalphaolefin PAO4, and the addition amount was 5 wt%, and the lubricant was obtained by ultrasonic dispersion to investigate its tribological properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com