Preparation method and application of nano MoS2-loaded carbon material compound

A technology of carbon materials and composites, which is applied in the field of preparation of carbon material-loaded nano-MoS2 composites, can solve the problems of cumbersome steps for carbon material-loaded nano-MoS2, and achieve excellent anti-friction and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A carbon material supported nano-MoS 2 The preparation method of complex, the steps are as follows,

[0020] Add a certain amount of ammonium tetrathiomolybdate and carbon nanomaterials to N,N-dimethylformamide, after the mixture is dispersed uniformly by ultrasonic waves, add hydrazine hydrate and continue ultrasonic dispersion;

[0021] Transfer the mixture obtained by ultrasonic dispersion to a solvothermal reaction kettle with a Teflon liner, seal the reaction kettle, heat it to 200 ° C for several hours, cool it, put it into a centrifuge, and centrifuge at a speed of 9000rpm. Washing with deionized water; the solid matter obtained after centrifugation was vacuum-dried overnight at 50°C to obtain the product, which is the carbon material @MoS 2 .

[0022] Further, the mass ratio of the carbon material to the ammonium tetrathiomolybdate is 2.2:1, the mass volume ratio to DMF is 1:1 mg / mL, and the mass volume ratio to hydrazine hydrate is 100:1 mg / mL.

[0023] Furt...

Embodiment 1

[0029] A carbon material supported nano-MoS 2 The preparation method of complex, the steps are as follows:

[0030] 27.5mg (NH 4 ) 2 MoS 4 and 12.5 mg of carbon nanotubes (CNTs) were added to 12.5 mL of DMF, the mixture was ultrasonically treated for 10 min, and then 0.125 mL of hydrazine hydrate was added, and ultrasonic dispersion was continued for 30 min. The mixture was then transferred to a 50 mL solvothermal reaction kettle with a Teflon-lined tube. After sealing, heat to 200°C for 10 hours. The obtained reaction solution was placed in a centrifuge, centrifuged at 9000 rpm for 3 min, and washed with deionized water. The solid matter after centrifugation and washing was dried in vacuum at 50°C overnight, and the obtained product was carbon nanotube-loaded nano-MoS 2 Composite (CNTs@MoS 2 ).

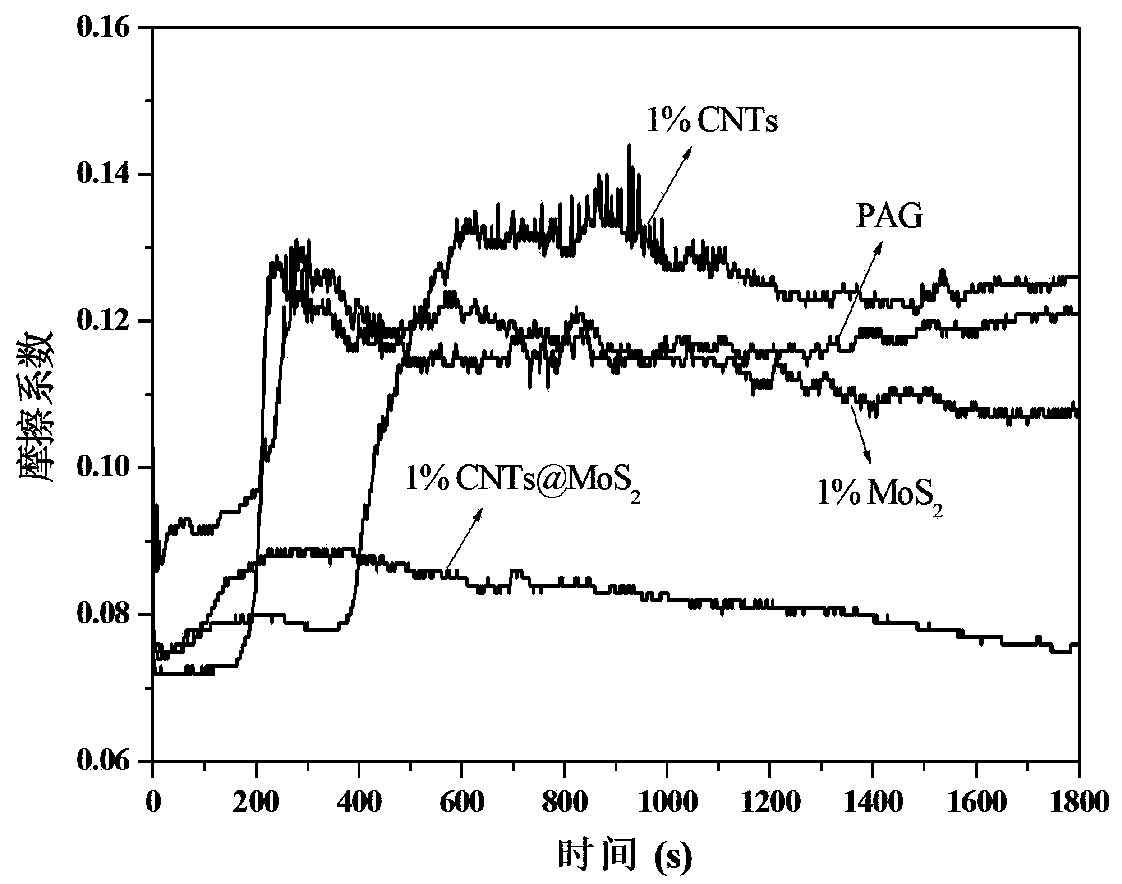

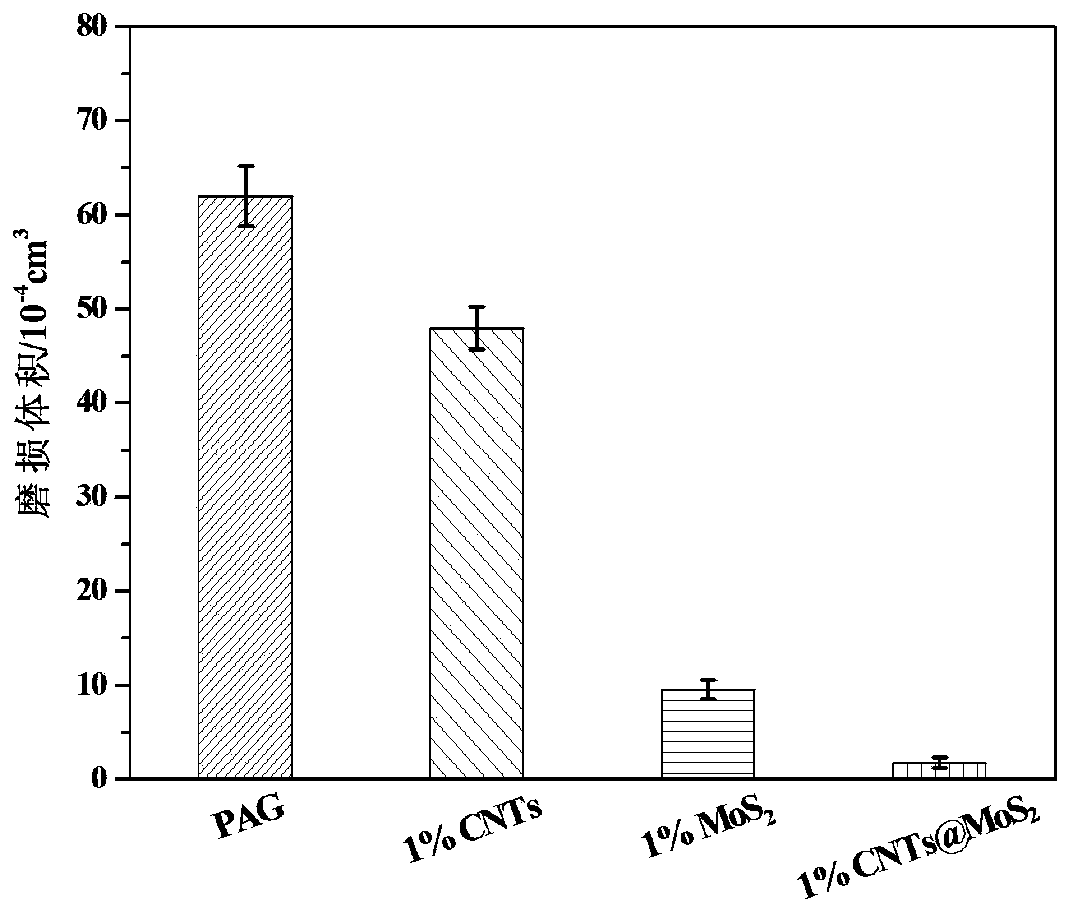

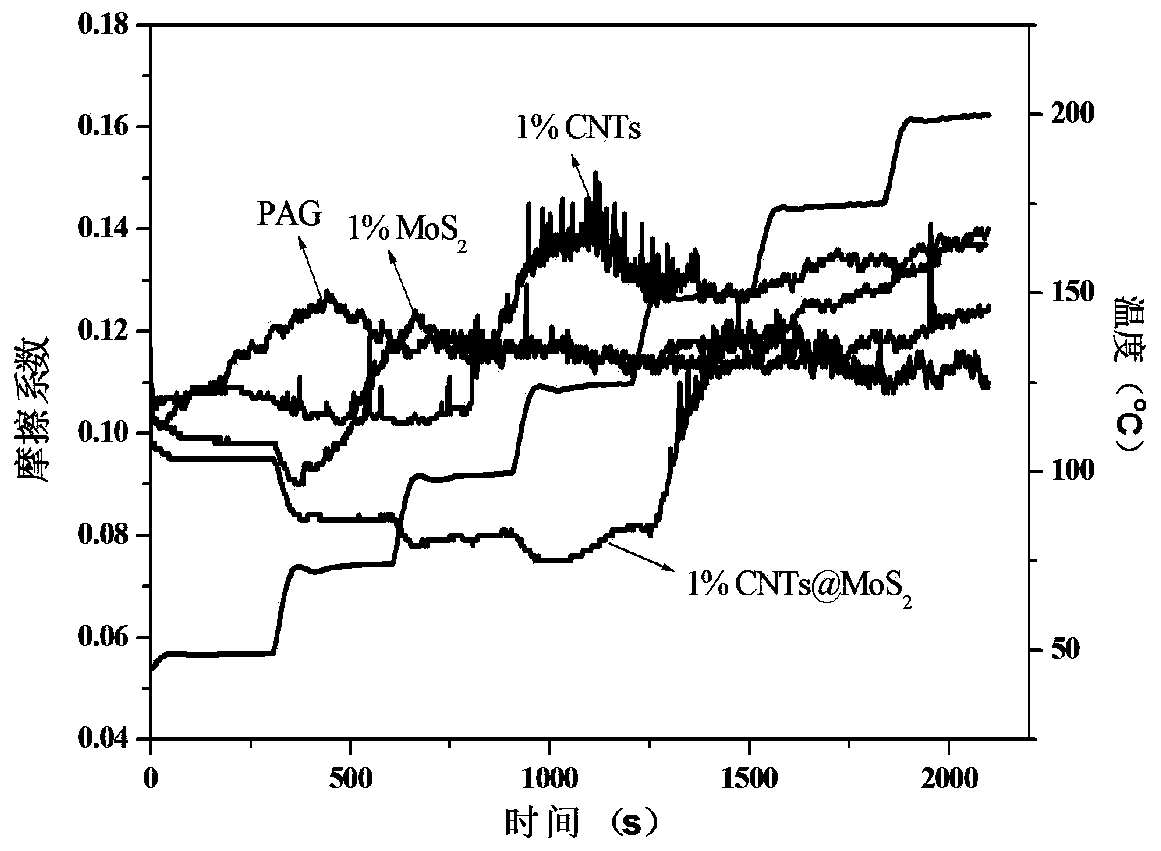

[0031] Add 1.0wt% CNTs, 1.0wt% MoS in polyether base oil 2 and 1.0wt% CNTs@MoS 2 , tested its tribological properties after ultrasonic dispersion.

Embodiment 2

[0033] A carbon material supported nano-MoS 2 The preparation method of complex, the steps are as follows:

[0034] 27.5mg (NH 4 ) 2 MoS 4 and 12.5 mg of fullerene C60 were added to 12.5 mL of DMF, the mixture was ultrasonically treated for 10 min, and then 0.125 mL of hydrazine hydrate was added, and ultrasonic dispersion was continued for 30 min. The mixture was then transferred to a 50 mL solvothermal reaction kettle with a Teflon-lined tube. After sealing, heat to 200°C for 10 hours. The obtained reaction solution was placed in a centrifuge, centrifuged at 9000 rpm for 3 min, and washed with deionized water. The solid matter after centrifugation and washing was dried in vacuum at 50°C overnight, and the product obtained was fullerene C60-loaded nano-MoS2 Composite (C60@MoS 2 ).

[0035] Add 1.0wt% C60, 1.0wt% MoS in polyether base oil 2 and 1.0 wt% C60@MoS 2 , tested its tribological properties after ultrasonic dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com