Graphene-hydrotalcite-like compound and preparation method and application thereof

A technology of hydrotalcite and graphene, which is applied in the field of graphene-hydrotalcite-like composites and its preparation, to achieve excellent anti-friction and anti-wear properties, high yield, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

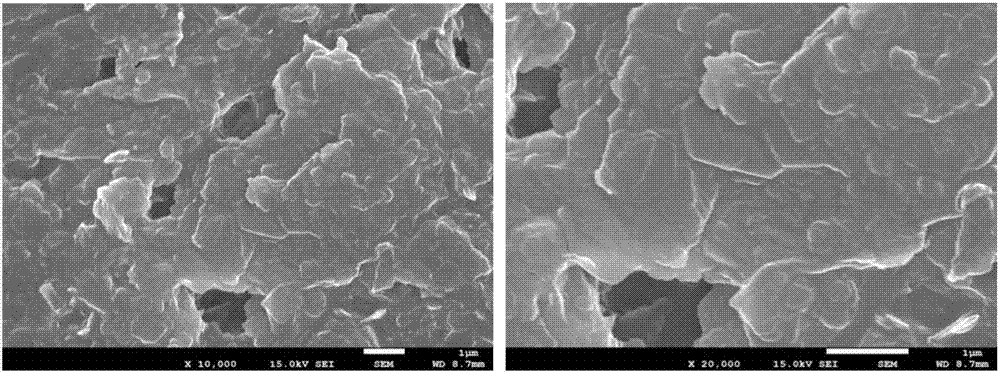

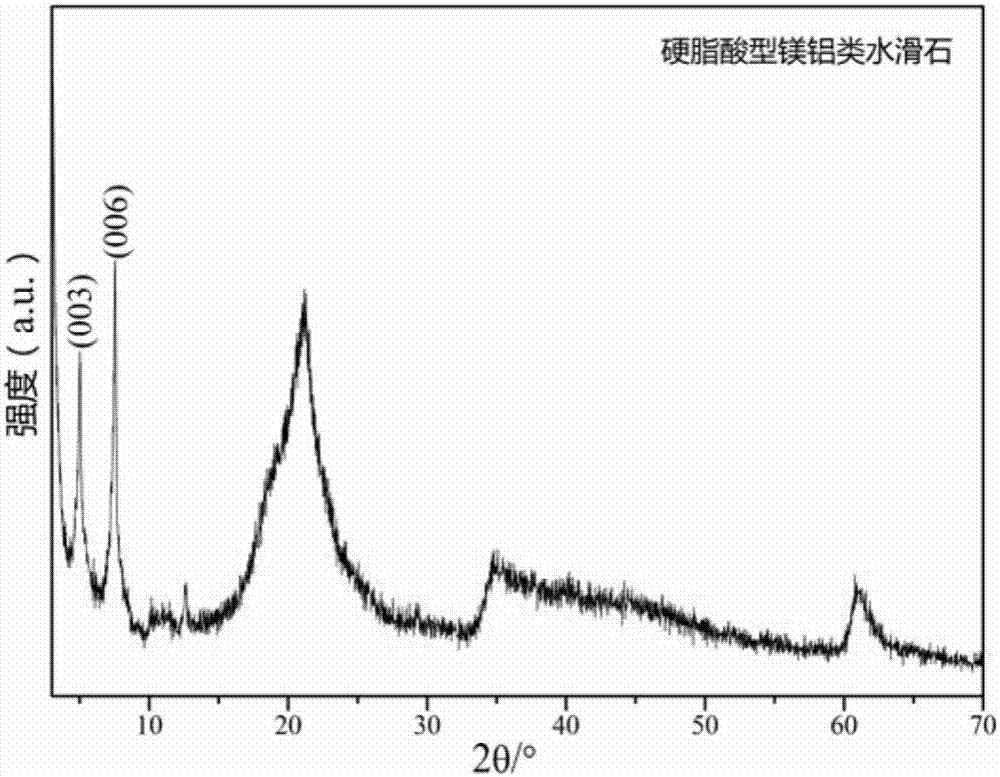

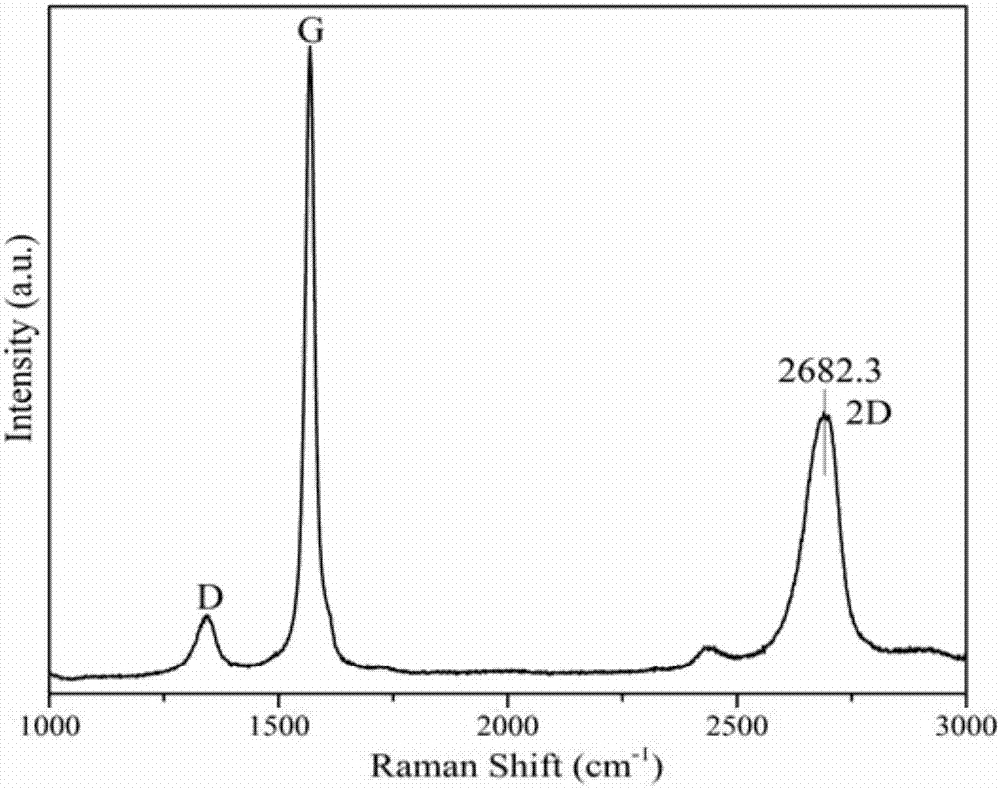

[0038] Embodiment 1, graphene-magnesium aluminum hydrotalcite compound and its preparation method and application

[0039] 1. Preparation of graphene-magnesium aluminum hydrotalcite composites

[0040] 1) One-step preparation of organically modified hydrotalcites: aluminum hydroxide is used as the aluminum source, magnesium nitrate hexahydrate is used as the magnesium source, 0.3mol / L sodium hydroxide solution is used as the precipitating agent, and the organic modifier is sodium stearate . Keep the metal salt concentration in the reaction solution at 0.3mol / L, the molar ratio of magnesium to aluminum metal ions is 2:1, and the amount of organic modifier is the same as that of aluminum hydroxide. Configure a certain amount of magnesium salt solution and precipitant solution according to the above requirements. Weigh the required amount of aluminum hydroxide powder and modifier powder, place them in a polytetrafluoroethylene-lined reactor, and mix them evenly; add the magnesi...

Embodiment 2

[0057] Embodiment 2, graphene oxide-cobalt aluminum hydrotalcite compound and its preparation method and application

[0058] 1. Preparation of graphene oxide-organically modified cobalt-aluminum hydrotalcite composites

[0059] 1) One-step preparation of organically modified hydrotalcites: Aluminum hydroxide is used as aluminum source, cobalt nitrate hexahydrate is used as cobalt source, 0.2mol / L sodium hydroxide solution is used as precipitant, and organic modifier is sodium laurate. Keep the metal salt concentration in the reaction solution at 0.25mol / L, the molar ratio of cobalt-aluminum metal ions at 3:1, and the amount of organic modifier used is the same as the molar amount of aluminum hydroxide. Configure a certain amount of cobalt salt solution and precipitant solution according to the above requirements. Weigh the required amount of aluminum hydroxide powder and modifier powder, place them in a polytetrafluoroethylene-lined reactor, and mix them evenly; add the coba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com