Nylon material for petroleum lining pipe and preparing method of nylon material

A technology of nylon and inner lining, which is applied in the field of high-resilience acid-resistant and high-temperature-resistant nylon material for petroleum lining pipes and its preparation. Social benefits, dimensional stability, excellent resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

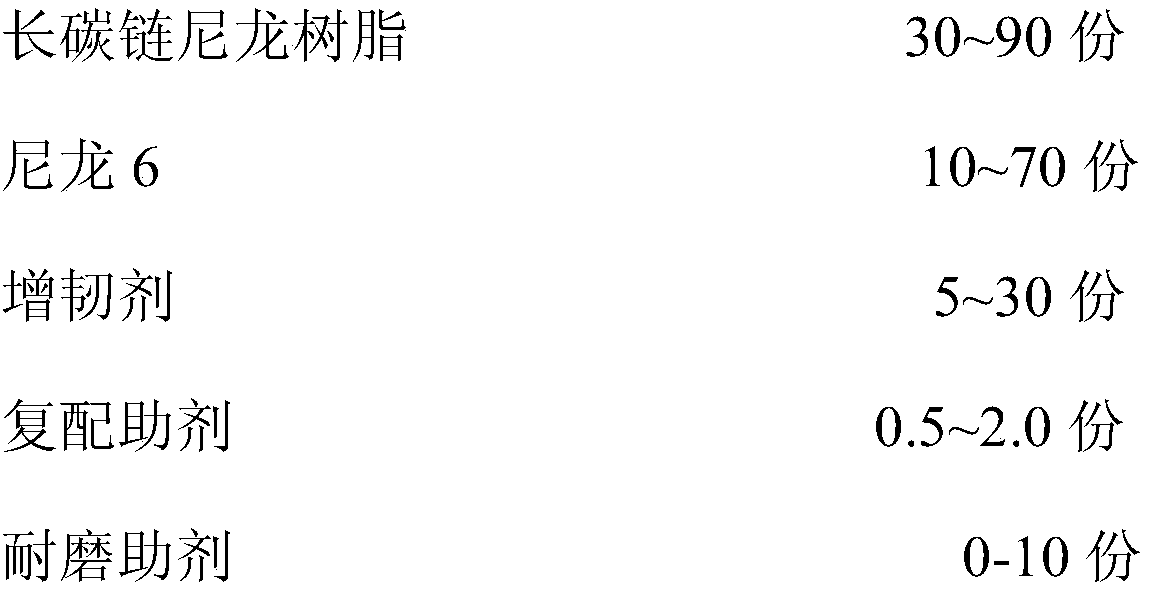

Method used

Image

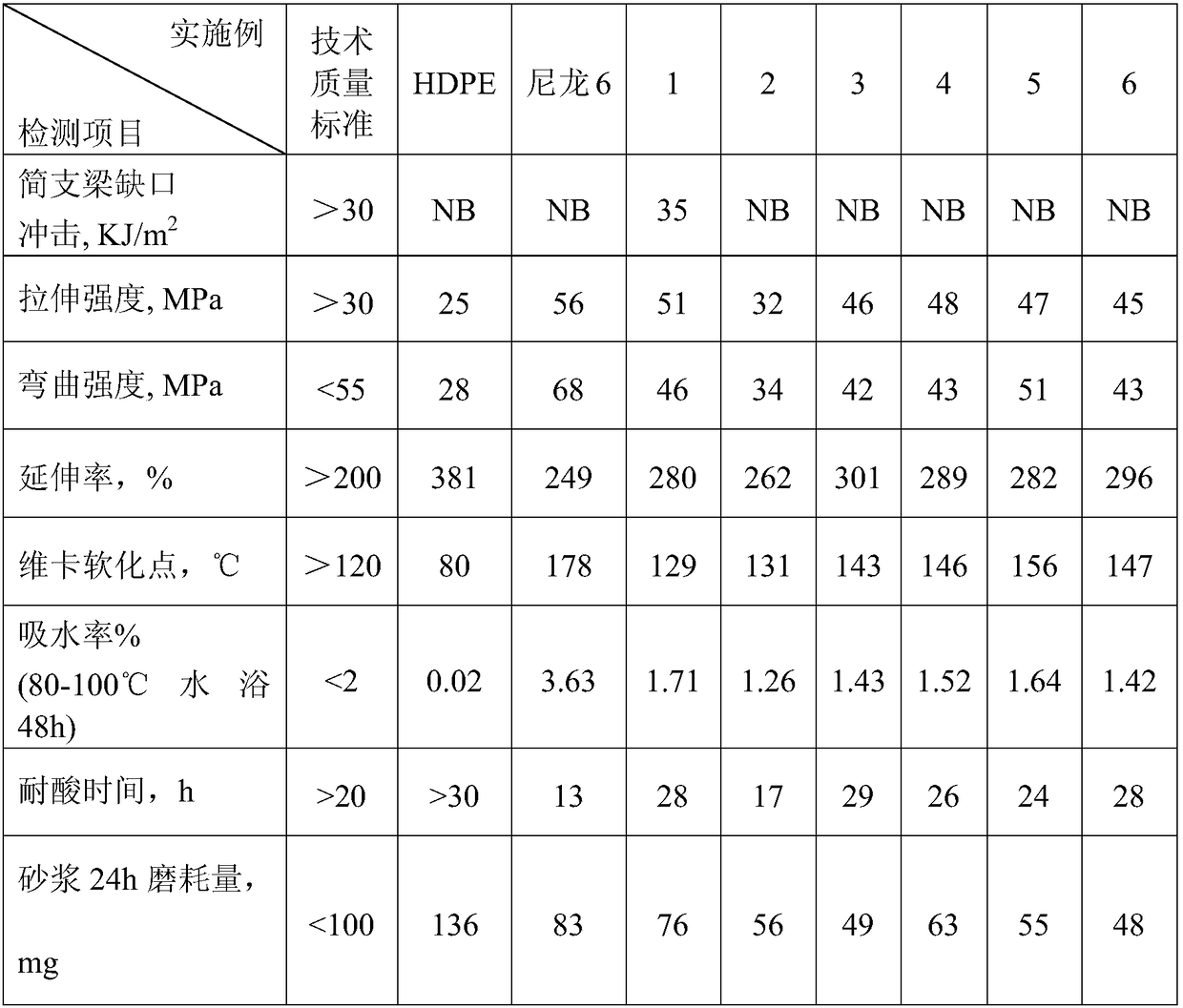

Examples

Embodiment 1

[0026] Firstly, Nylon 1012 and Nylon 6 resins were respectively added into a vacuum drum dryer, and solid-phase viscosity was increased at 160°C to a melt index of 0.3g / 10min, and moisture-proof packaging was carried out for use.

[0027] Then add 90 kg of tackified nylon 1012 resin, 10 kg of tackified nylon 6 resin, 5 kg of toughening agent EPDM-G, and 0.5 kg of compounding additives into the high mixer in sequence, first mix at low speed for 30 seconds, and then mix at high speed. After mixing for 3 minutes, discharge the materials for later use.

[0028] Set the temperature of each section as: feeding section 160°C, melting section 200-240°C, head section 240°C.

[0029] After the temperature of each section of the relevant extruder reaches the set temperature and the screw can be rotated by hand, after cleaning the equipment with nylon 6 raw material, add the mixed material into the extruder for mixing and extrusion, and the screw speed is 15Hz.

[0030] The strips are dr...

Embodiment 2

[0033] Firstly, Nylon 610 and Nylon 6 resins were respectively added into a vacuum drum dryer, and solid-phase viscosity was increased at 180°C to a melt index of 3g / 10min, and moisture-proof packaging was carried out for use.

[0034] Then 30 kg of tackified nylon 610 resin nylon 6, 70 kg of tackified nylon 6 resin, 30 kg of toughening agent EPDM-G, 2 kg of compounding additives, 10 kg of wear-resistant additive super high PE , then added to the high mixer in turn, mixed at low speed for 30 seconds, then mixed at high speed for 8 minutes, and then discharged for later use.

[0035] Set the temperature of each section as: feeding section 200°C, melting section 240-260°C, head section 260°C.

[0036] After the temperature of each section of the relevant extruder reaches the set temperature and the screw can be rotated by hand, after cleaning the equipment with nylon 6 raw material, add the mixed material to the extruder for mixing and extrusion, and the screw speed is 45Hz.

...

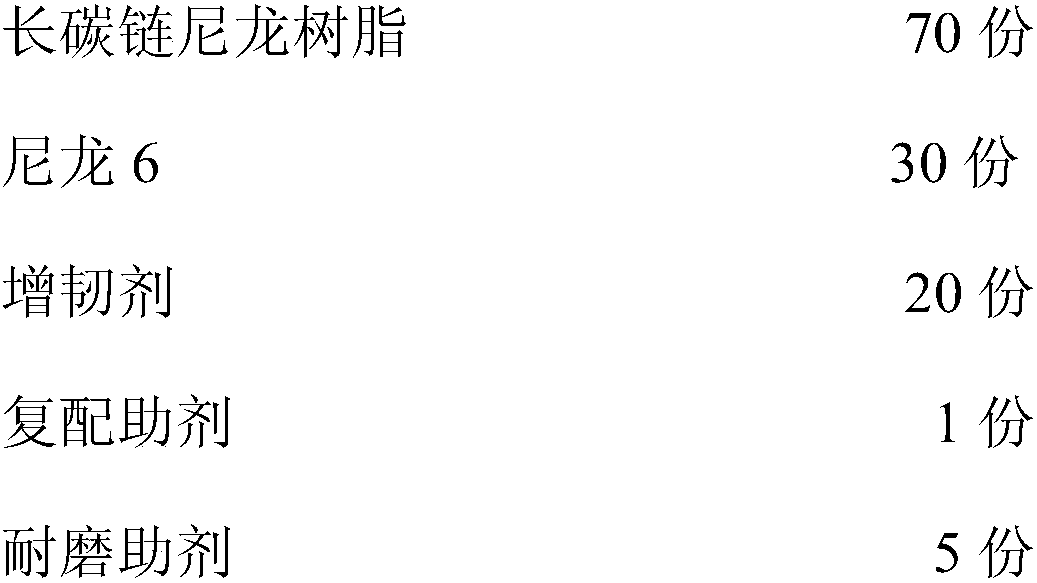

Embodiment 3

[0040] Firstly, Nylon 612 and Nylon 6 resins were respectively added into a vacuum drum dryer, and solid-phase viscosity was increased at 180°C to a melt index of 1.5g / 10min, and moisture-proof packaging was carried out for use.

[0041] Then 70 kg of tackified nylon 612 resin, 30 kg of tackified nylon 6 resin, 20 kg of toughening agent EPDM-G, 1 kg of compounding additive, and 5 kg of wear-resistant additive ultra-high PE were used in sequence. Put it into the high mixer and mix it at low speed for 30s, then mix it at high speed for 5 minutes, then discharge it for later use.

[0042] Set the temperature of each section as: feeding section 180°C, melting section 230-250°C, head section 250°C.

[0043] After the temperature of each section of the relevant extruder reaches the set temperature and the screw can be rotated by hand, the equipment is cleaned with nylon 6 raw material, and the mixed material is added to the extruder for mixing and extrusion, and the screw speed is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap