Micronano bioactive glass microsphere prepared by microemulsion technology and preparation method thereof

A bioactive glass, micro-nano technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of uneven particle size distribution, particle agglomeration, poor dispersion, etc., and achieve the effect of solving serious agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

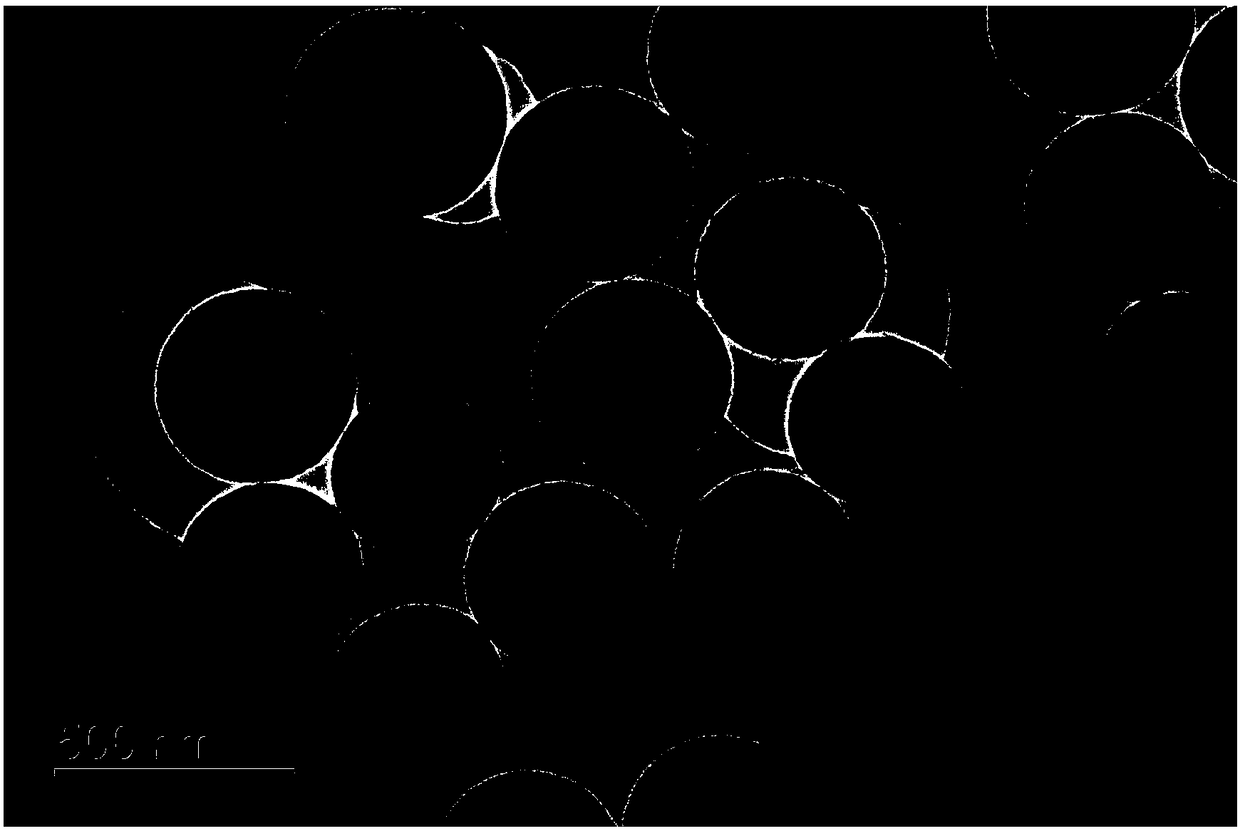

Image

Examples

Embodiment 1

[0028] A micronano bioactive glass microsphere prepared by microemulsion technology, the preparation method of which is as follows:

[0029] (1) Add 2g of cetyltrimethylammonium bromide and 15ml of cyclohexane to a mixed solution of 180ml of deionized water and 120ml of absolute ethanol in sequence, and stir evenly to form a microemulsion.

[0030] (2) Add 4.05ml tetraethyl orthosilicate, 1.5ml ammonia water (25wt%), 0.42ml triethyl phosphate and 2.574g calcium nitrate tetrahydrate to the microemulsion obtained in step (1) in sequence, and stir evenly to obtain Bioactive glass gel solution.

[0031] (3) Centrifuge the bioactive glass gel solution obtained in step (2), wash to obtain a wet gel precipitate, and then place the wet gel precipitate in an oven at 60°C to dry for 2 days to obtain a bioactive glass Gel powder.

[0032] (4) Heat-treating the bioactive glass gel powder in a high-temperature furnace at 650° C. for 3 hours to obtain micro-nano bioactive glass microspher...

Embodiment 2

[0035] A micronano bioactive glass microsphere prepared by microemulsion technology, the preparation method of which is as follows:

[0036] (1) Add 1g of cetyltrimethylammonium bromide and 15ml of cyclohexane to a mixed solution of 180ml of deionized water and 60ml of absolute ethanol in sequence, and stir evenly to form a microemulsion.

[0037] (2) Add 4.05ml tetraethyl orthosilicate, 1ml ammonia water (25wt%), 0.42ml triethyl phosphate and 2.574g calcium nitrate tetrahydrate to the microemulsion obtained in step (1) in sequence, stir well to obtain biological Active glass gel solution.

[0038] (3) Centrifuge the bioactive glass gel solution obtained in step (2), wash to obtain a wet gel precipitate, and then place the wet gel precipitate in an oven at 50°C to dry for 2 days to obtain bioactive glass Gel powder.

[0039] (4) Heat-treating the bioactive glass gel powder in a high-temperature furnace at 620° C. for 3 hours to obtain micro-nano bioactive glass microspheres....

Embodiment 3

[0042] A micronano bioactive glass microsphere prepared by microemulsion technology, the preparation method of which is as follows:

[0043] (1) Add 3.5g of cetyltrimethylammonium bromide and 30ml of cyclohexane to a mixed solution of 180ml of deionized water and 150ml of absolute ethanol in sequence, and stir evenly to form a microemulsion.

[0044] (2) Add 8.1ml tetraethyl orthosilicate, 3ml ammonia water (25wt%), 0.84ml triethyl phosphate and 5.148g calcium nitrate tetrahydrate to the microemulsion obtained in step (1) in sequence, stir evenly to obtain biological Active glass gel solution.

[0045] (3) Centrifuge the bioactive glass gel solution obtained in step (2), wash to obtain a wet gel precipitate, and then place the wet gel precipitate in an oven at 80°C to dry for 1 day to obtain a bioactive glass Gel powder.

[0046] (4) Heat-treating the bioactive glass gel powder in a high-temperature furnace at 700° C. for 2 hours to obtain micro-nano bioactive glass microsph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com