Method for directional production of singlet oxygen by activating persulfate via carbonylation carbon material

A technology for activating persulfate and carbonylated carbon, which is applied in chemical instruments and methods, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problems of toxic and harmful substances and unfavorable separation of photosensitizers, and achieve Ease of transportation, high economy, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

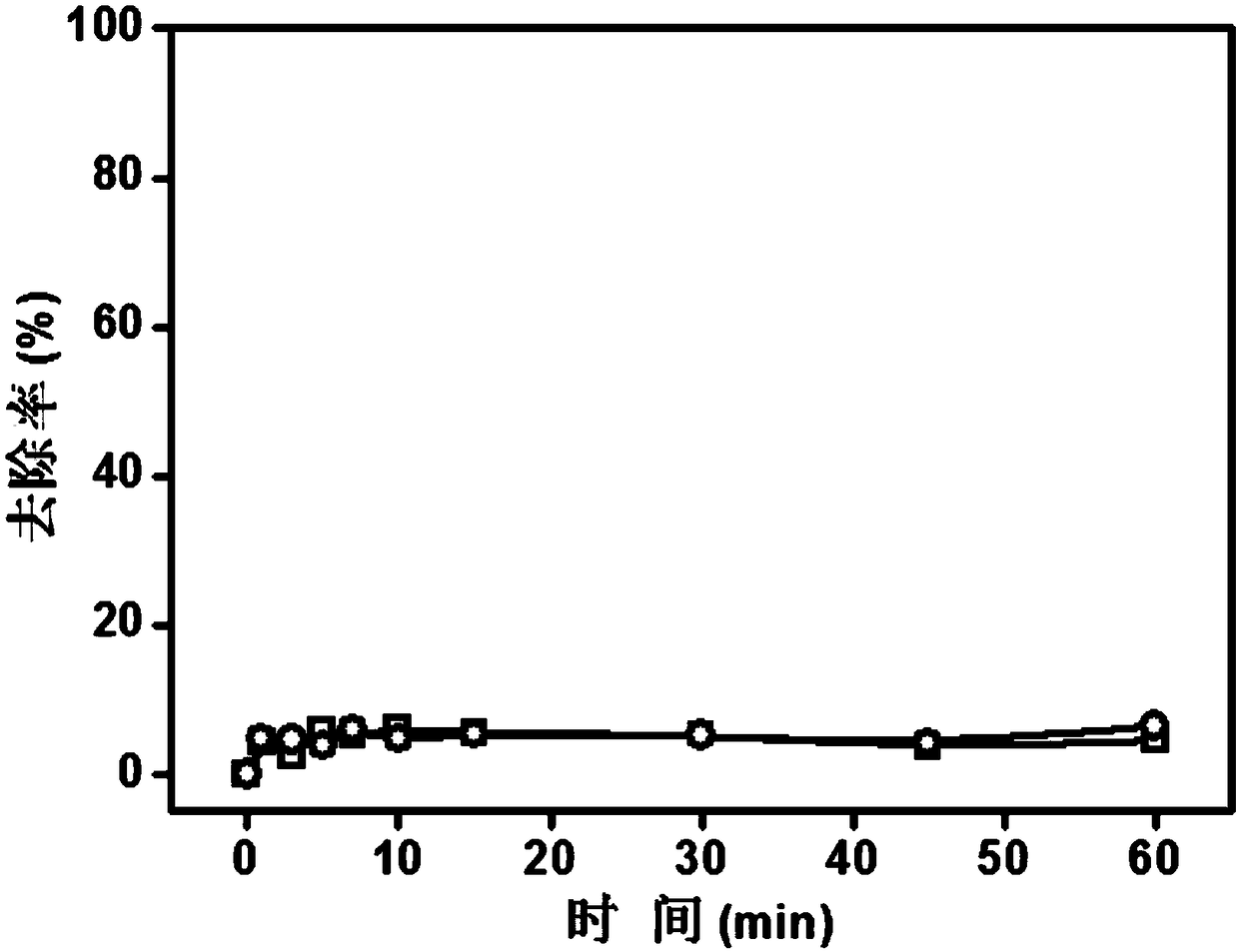

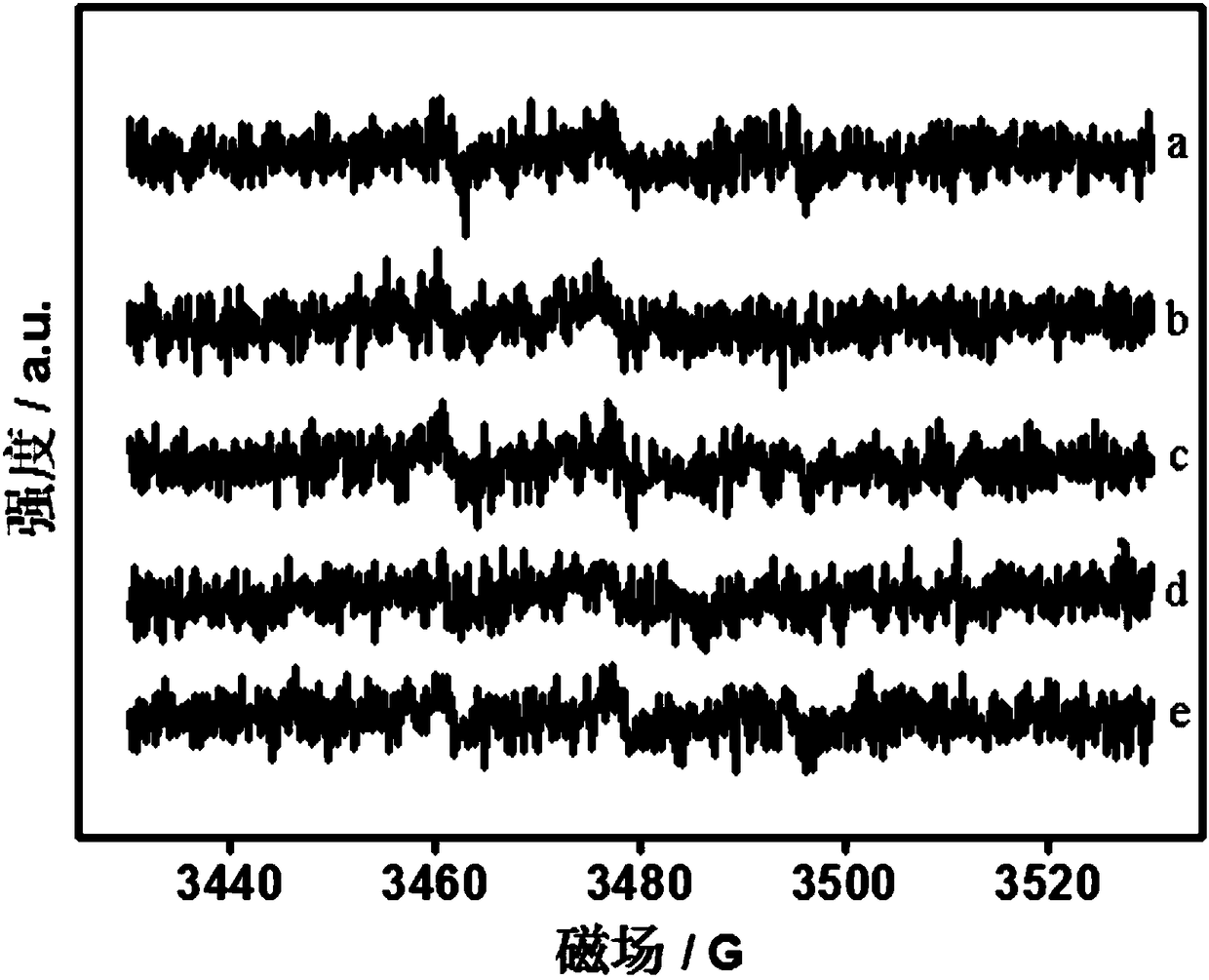

[0026] Embodiment 1: This embodiment is a method for activating persulfate directional generation of singlet oxygen by carbonylation carbon material, which is specifically carried out according to the following steps:

[0027] The carbonylation carbon material is added to the sewage to be treated and stirred for 5-10 minutes, and then an aqueous solution of persulfate is added to obtain a mixed solution, and the mixed solution can be continuously stirred to generate singlet oxygen to treat the sewage;

[0028] The carbon material in the carbonylation carbon material is amorphous carbon material, sp 2 Hybrid carbon materials and sp 3 A carbon material composed of one or two hybridization methods in the hybrid carbon material;

[0029] The concentration of carbonylation carbon material in the mixed solution is 0.01g / L~5g / L;

[0030] The concentration of persulfate in the mixed solution is 0.1 mmol / L to 10 mmol / L.

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the amorphous carbon material is activated carbon or mesoporous carbon. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the sp 2 Hybrid carbon materials are carbon nanotubes, graphene or fullerenes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com