Conveyor belt for grain spreading machine and grain spreading machine with same

A technology of conveyor belt and leveling machine, which is used in conveyors, transportation and packaging, loading/unloading, etc., can solve the problem of non-abrasion of conveyor belt materials, reduce labor intensity, improve conveyor belt materials, and facilitate unmanned The effect of intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

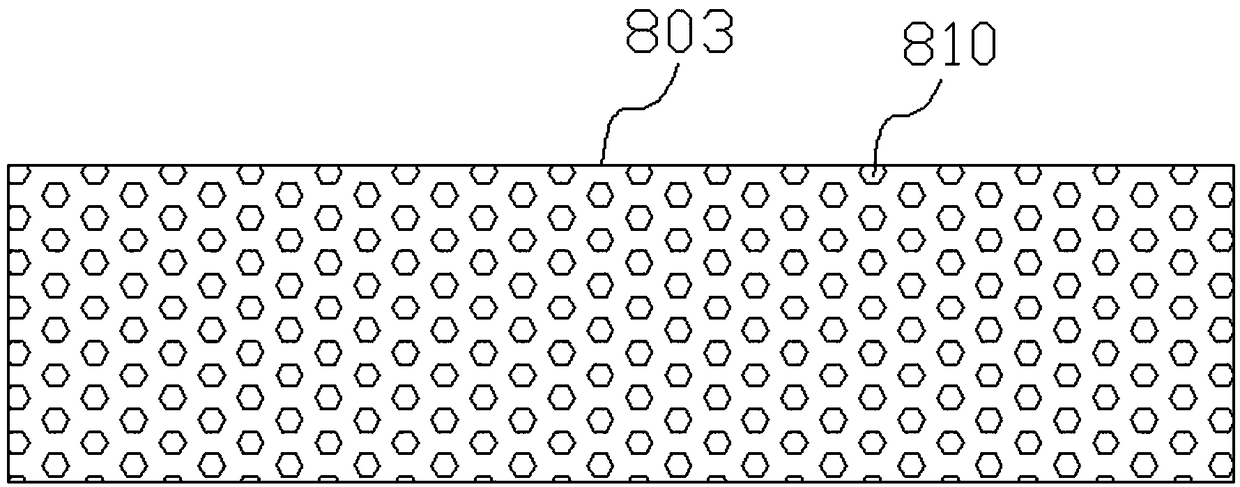

[0047] see figure 1 , a conveyor belt for a grain leveling machine, including a conveyor belt 803, the conveyor belt 803 is made of modified rubber material, and the surface of the conveyor belt 803 is uniformly provided with granular anti-slip protrusions 810, and the anti-slip protrusions 810 are circular structure with a diameter of 0.35cm.

[0048] The above conveyor belt 803 is made of the following components in parts by weight: 90 parts of polyisoprene rubber, 16 parts of calcined kaolin powder, 0.6 parts of active calcium, 1.2 parts of vulcanizing agent, 4 parts of short glass, modified zeolite powder 2.2 parts, 1.2 parts of polypropylene glycol diglycidyl ether, 4.5 parts of metallocene polyethylene, 3 parts of nano-silica, 0.5 parts of tetrahydrophthalic anhydride;

[0049] The processing method of above-mentioned modified zeolite powder is as follows:

[0050] (1) Roast zeolite powder of 80-120 mesh at 280-350° C. for 2 hours, and take it out after natural cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com