Crawler type grain spreading machine

A kind of unwinding machine and crawler-type technology, which is applied in the direction of belts, conveyors, conveyor objects, etc., can solve the problems of low efficiency and unmovable unloading machine, achieve delayed grain throwing position, facilitate unmanned intelligent operation, and improve Effect of Conveyor Belt Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

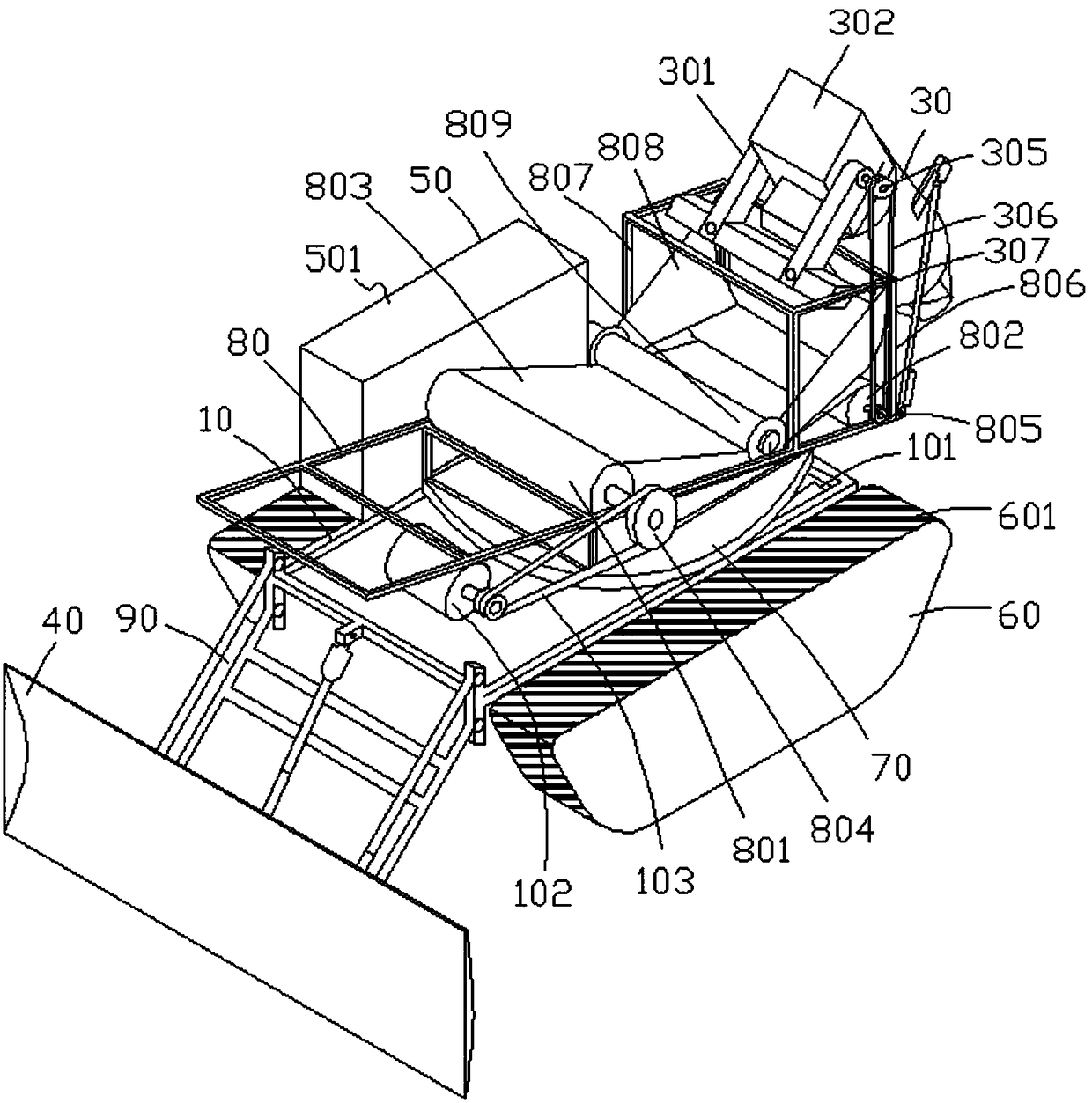

[0047] see figure 1 , a crawler type grain leveling machine, comprising: a chassis 10, a first drive motor 101, a grain conveying auger 30, a grain pushing shovel 40, a control system 50 and a drive wheel 60, and the control system 50 is installed in a box body 501 , the box body 501 is fixed on the upper part of one side of the chassis 10, and the chassis 10 is made of aluminum alloy and has a square structure; the first driving motor 101 is installed at the bottom of the chassis 10, and the driving wheels 60 are installed on side, and the drive wheel 60 is powered by the first drive motor 101 . The first driving motor 101 is connected with the control system 50, and accepts the control instructions of the control system 50; the chassis 10 is equipped with a turntable 70, and the turntable 70 is equipped with a grain transport support 80, and the grain transport support 80 is equipped with throwing Grain conveyor, underframe 10 front ends are equipped with push plate support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com