Method for preparing lithium strip by fused deposition

A technology of fused deposition and lithium ribbon, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, and electrolyte battery manufacturing, etc., can solve the problems of large equipment investment, rough coating, and difficulty in ensuring the uniformity of lithium film, and achieve raw material utilization The effect of high efficiency and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

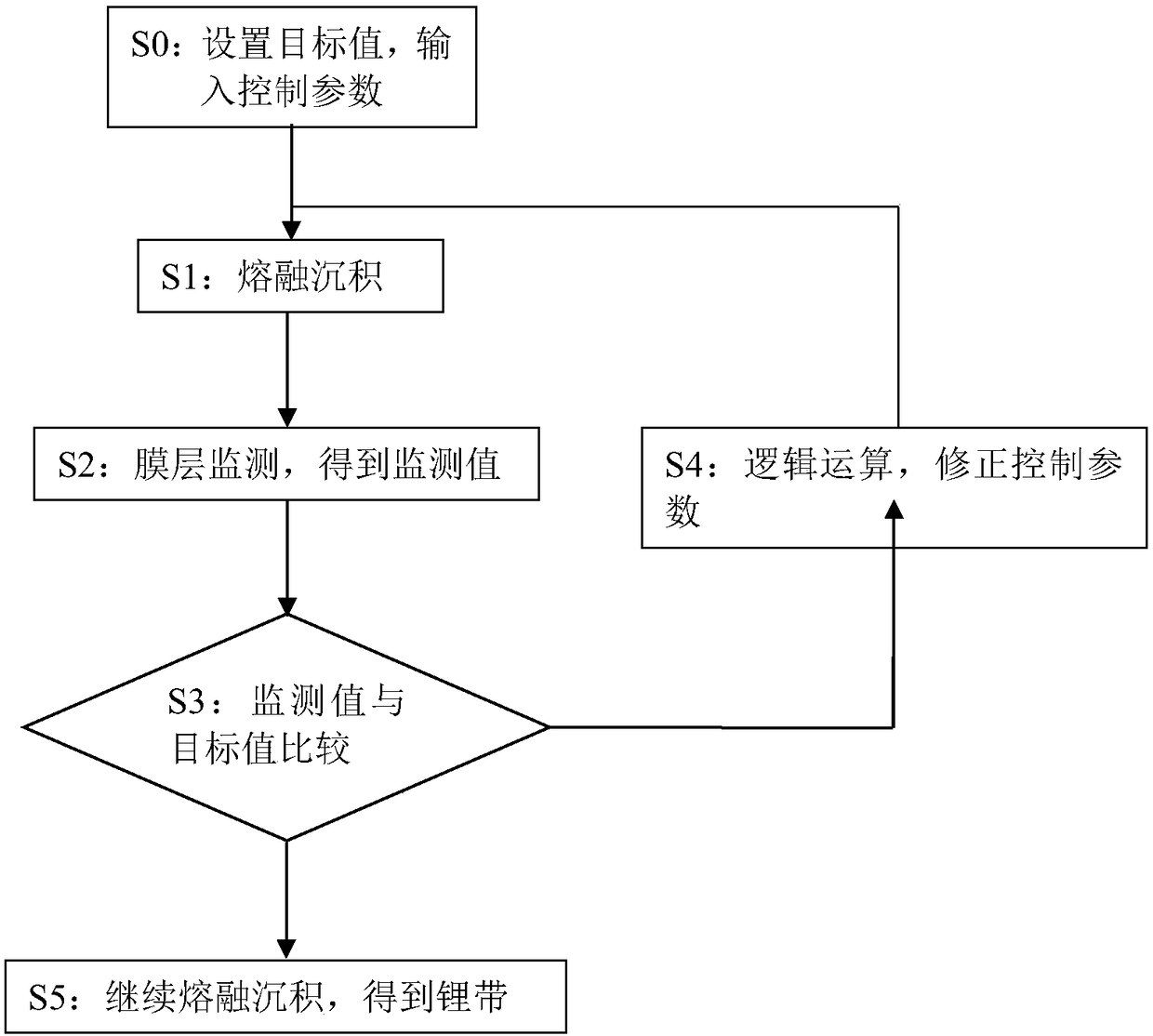

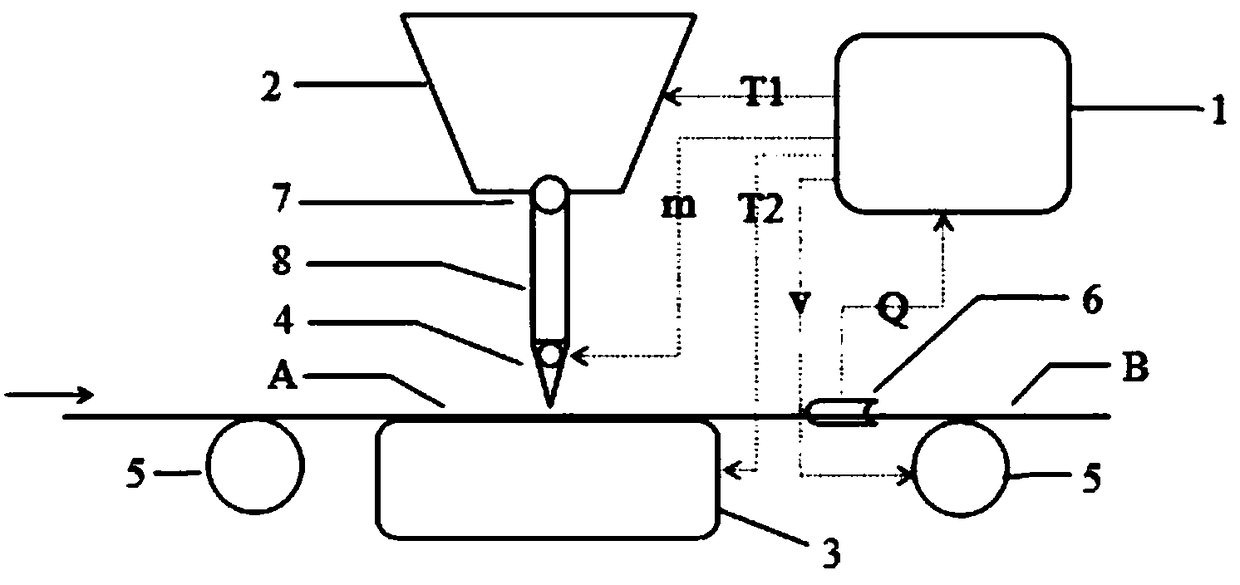

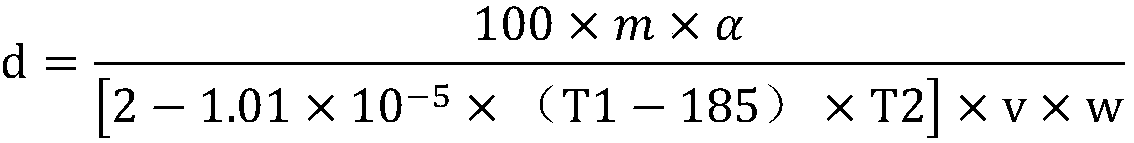

[0067] A 10 μm thick lithium metal film was fused deposited using a 10 μm thick copper foil. Such as figure 2 As shown, the control system 1 is used to perform logic operations and specific parameter regulation. Firstly, a 10 μm thick lithium film deposition program is written and input into the control system 1. The pre-treated copper foil is transferred to the heater platform 3 for preheating through the transfer wheel 5, the molten lithium liquid is placed in the molten lithium tank 2, filtered by the filter device 7, flows into the constant temperature transfer device 8, and finally enters the controllable precision coating head 4, The width of the controllable precision coating head 4 is 50mm.

[0068] At the beginning of fusion deposition, input the initial control parameter value at will, including the temperature T1 of the lithium liquid in the molten lithium tank 2, the temperature T2 of the copper foil heated in the heating platform 3, the amount of lithium produce...

Embodiment 2

[0070] A 30 μm thick lithium metal film was fused deposited on a copper foil with a thickness of 10 μm. Such as figure 2 As shown, the control system 1 is used to perform logic operations and specific parameter regulation. Firstly, a 10 μm thick lithium film deposition program is written and input into the control system 1. The pre-treated copper foil is transferred to the heater platform 3 for preheating through the transfer wheel 5, the molten lithium liquid is placed in the molten lithium tank 2, filtered by the filter device 7, flows into the constant temperature transfer device 8, and finally enters the controllable precision coating head 4, The width of the controllable precision coating head 4 is 50mm.

[0071] At the beginning of fusion deposition, input the initial control parameter value at will, including the temperature T1 of the lithium liquid in the molten lithium tank 2, the temperature T2 of the copper foil heated in the heating platform 3, the amount of lith...

Embodiment 3

[0073] A 100 μm thick lithium metal film was fused deposited using a 10 μm thick copper foil. Such as figure 2 As shown, the control system 1 is used to perform logic operations and specific parameter regulation. Firstly, a 10 μm thick lithium film deposition program is written and input into the control system 1. The pre-treated copper foil is transferred to the heater platform 3 for preheating through the transfer wheel 5, the molten lithium liquid is placed in the molten lithium tank 2, filtered by the filter device 7, flows into the constant temperature transfer device 8, and finally enters the controllable precision coating head 4, The width of the controllable precision coating head 4 is 50mm.

[0074] At the beginning of fusion deposition, input the initial control parameter value at will, including the temperature T1 of the lithium liquid in the molten lithium tank 2, the temperature T2 of the copper foil heated in the heating platform 3, the amount of lithium produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com