High-efficiency heat accumulation type tube heating furnace system

A tubular heating furnace and regenerative technology, applied in the direction of improving energy efficiency, lighting and heating equipment, furnaces, etc., can solve the problems of long service life, low comprehensive investment, small footprint of tubular furnaces, etc., and achieve automation The effect of high level and reduced system investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below in conjunction with the drawings and embodiments.

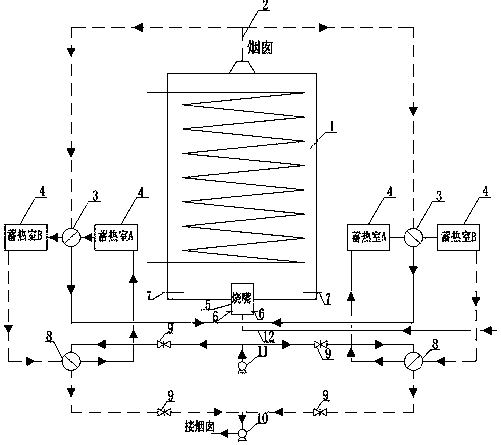

[0026] With reference to the drawings, the present invention is a high-efficiency regenerative tubular heating furnace system, which includes a 1-tube furnace body, a 2-chimney, a 3-high temperature four-way reversing valve, a 4-regenerator, and a 5-burner. 6-small fire detector, 7-large fire detector, 8-low temperature four-way reversing valve, 9-distribution valve, 10-induced draft fan, 11-blower, 12-gas inlet; tube heating furnace system burns through gas Combustion and combustion air are mixed and combusted at the burner 5, heated by the heating medium in the tube furnace body 1, and the generated tail gas is passed from the chimney 2 through the high-temperature four-way reversing valve 3 through the regenerator 4 and the low-temperature four-way reversing valve 8. Discharged by the induced draft fan 11, the combustion-supporting air passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com