Lift axle control unit for a motor vehicle

A technology of control unit and electronic control unit, which is applied in the lift shaft suspension system and the field of vehicles and commercial vehicles. It can solve the problems of design complexity, manufacturing cost, excessive air, and high manufacturing cost, and achieve the effect of reducing hardware cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

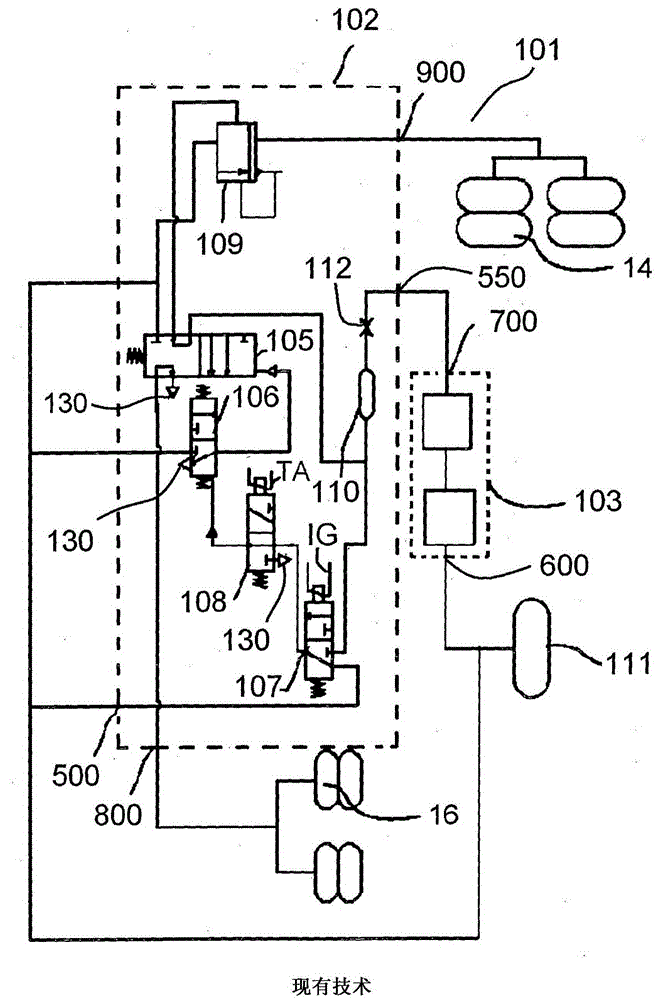

[0040] refer to figure 1 , a prior art lift axle control system 101 includes two devices, both shown in dashed lines: a lift axle control valve 102 and a load sense valve 103 . Furthermore, a pressurized air container 111 , a suspension bellows 14 and a lifting bellows 16 are provided. The lift shaft control valve 102 comprises a spool valve 105, a differential pressure valve 106, a first solenoid valve 107 for receiving an ignition signal IG, a second solenoid valve 108 for receiving an electrical override signal TA and for enabling manual override , relay valve 109, damping container 110 and small hole (throttle valve) 112.

[0041] The delivery pressure 700 of the load sense valve 103 is given as a control input 550 to the lift axle control valve 102 . Control input 550 is then given to damping container 110 through aperture 112 . The control pressure from the damping container 110 is given to the differential pressure valve 106 through the first solenoid valve 107 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com