Melt stirring type multifunctional anti-gravity casting device and casting method

An anti-gravity casting and stirring technology, which is applied in the fields of melt-stirring multi-functional anti-gravity casting devices and electromagnetic stirring multi-functional anti-gravity casting devices, can solve the problem of long standing time, many preparation procedures, and inability to use multiple Anti-gravity casting method and other issues, to achieve the effect of stabilizing the uniformity of melt composition, reducing gas content, and improving the quality and performance of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

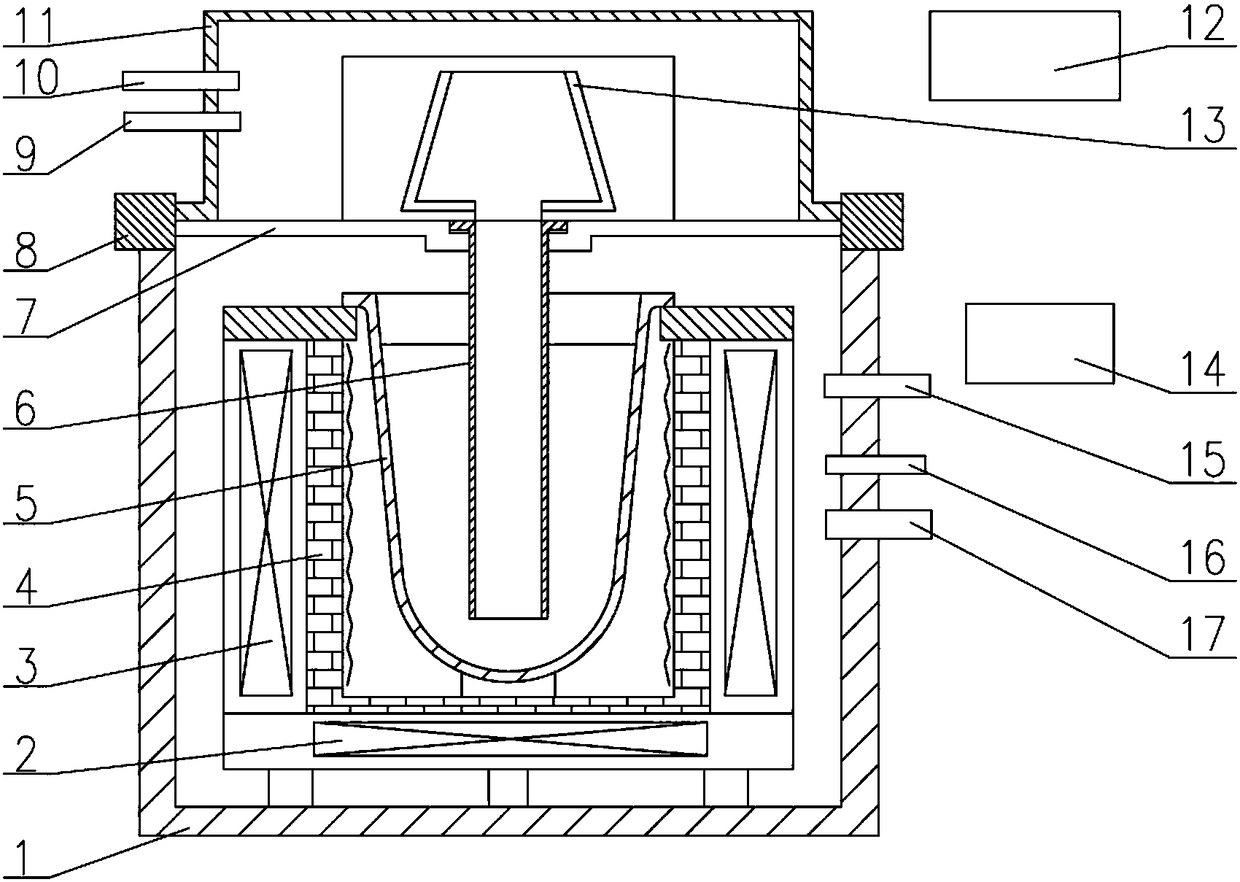

[0028]Embodiment 1: Put the aluminum-based composite material in the crucible 5, energize and heat the melting furnace 4, cover the middle partition 7, and seal the lower pressure tank 1, and vacuumize the lower pressure tank 1; after the metal material is melted, The variable frequency power supply 14 controls the current magnitude and direction of the side strong magnet 3 and the bottom strong magnet 2, so that an alternating electromagnetic field is generated inside the metal melt, and the melt rotates horizontally and turns up and down under the action of alternating electromagnetic thrust, so that the melt The gas in the body is precipitated under vacuum diffusion and stirring convection, so as to achieve the purpose of vacuum stirring and degassing of the melt. When the melt temperature reaches the pouring temperature, disconnect the vacuum, insert the liquid riser 6, place and fix the mold 13, cover the upper pressure tank 11, and lock the lower pressure tank 1, the uppe...

Embodiment 2

[0029] Embodiment 2: Put the magnesium-based composite material into the crucible 5, heat the melting furnace 4, cover the middle partition 7, and seal the lower pressure tank 1, and vacuumize the lower pressure tank 1; after the metal material is melted, The variable frequency power supply 14 controls the current magnitude and direction of the side strong magnet 3 and the bottom strong magnet 2, so that an alternating electromagnetic field is generated inside the metal melt, and the melt rotates horizontally and turns up and down under the action of alternating electromagnetic thrust, so that the melt The gas in the body is precipitated under vacuum diffusion and stirring convection, so as to achieve the purpose of vacuum stirring and degassing of the melt. When the melt temperature reaches the pouring temperature, disconnect the vacuum, insert the liquid riser 6, place and fix the mold 13, cover the upper pressure tank 11, and lock the lower pressure tank 1, the upper pressur...

Embodiment 3

[0030] Example 3: Put ZL205A alloy material into the crucible 5, and heat the melting furnace 4. After the metal material is melted, the molten metal is degassed by hanging rotary spraying; after the degassing is completed, turn on the frequency conversion power supply 14. The variable frequency power supply 14 controls the current magnitude and direction of the side strong magnet 3 and the bottom strong magnet 2, so that an alternating electromagnetic field is generated inside the metal melt, and the melt rotates horizontally and turns up and down under the action of alternating electromagnetic thrust, To achieve the purpose of strengthening the internal convection of the melt. When the melt temperature reaches the pouring temperature, cover the middle partition 7, insert the riser 6, place and fix the mold 13, and lock and seal the lower pressure tank 1 and the middle partition 7 by the locking ring 8; Under the control of the computer and the air circuit control system 12, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com