Preparation method of iron or copper oxide pillared layered manganese oxide low-temperature denitration catalyst

A layered manganese oxide and low-temperature denitrification technology, applied in the field of denitrification catalysts, can solve the problems of poor thermal stability, limitation, and small specific surface area, and achieve high sulfur resistance, good low-temperature denitrification activity, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Preparation of hydroxide:

[0055] Dissolve manganese acetate and ferric nitrate in deionized water to prepare a mixed aqueous solution of manganese and iron, and then add 1 part of the mixed aqueous solution of manganese and iron dropwise to 1 part of aqueous potassium hydroxide in parts by volume. With stirring, an aqueous solution of mixed hydroxides of manganese and iron was obtained; wherein, 1.43 g of ferric nitrate, 4.92 g of manganese acetate, and 30 ml of deionized water. The potassium hydroxide molar concentration of potassium hydroxide aqueous solution is 8mol / L, and the rate of addition is 2ml / min;

[0056] (2) Oxidation of hydroxide:

[0057] In parts by volume, add 1.7 parts of 10g / L potassium permanganate aqueous solution dropwise at a rate of 2ml / min to 1 part of manganese and iron mixed hydroxide aqueous solution obtained in step (1), at 40°C under stirring conditions Oxidation reaction 72h;

[0058] (3) Suction filtration and washing:

[0059] ...

Embodiment 2

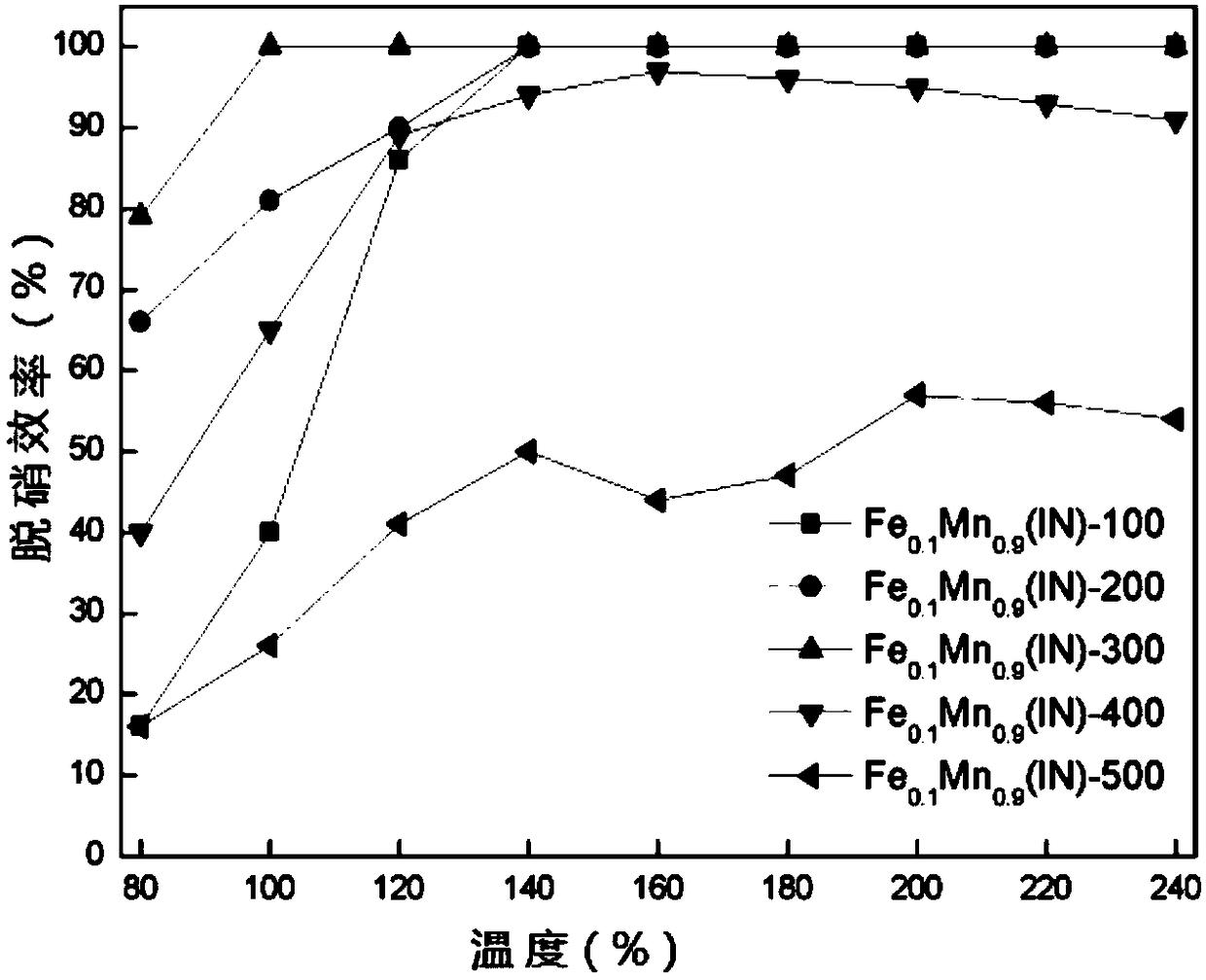

[0065] The steps and conditions of the preparation method of this embodiment are basically the same as those of Example 1, except that the ferric nitrate is 0.9 g, the manganese acetate is 4.92 g, and the deionized water is 30 ml. Finally, the iron oxide pillared layered manganese oxide low-temperature denitrification catalyst is obtained, which is denoted as Fe 0.1 mn 0.9 (IN)-300.

Embodiment 3

[0067] The steps and conditions of the preparation method of this embodiment are basically the same as those of Example 1, except that the ferric nitrate is 0.43 g, the manganese acetate is 4.92 g, and the deionized water is 30 ml. Finally, the iron oxide pillared layered manganese oxide low-temperature denitrification catalyst is obtained, which is denoted as Fe 0.05 mn 0.95 (IN)-300.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com