Apparatus for additive manufacturing of three-dimensional objects

A three-dimensional object, additive technology, used in machining, additive manufacturing, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

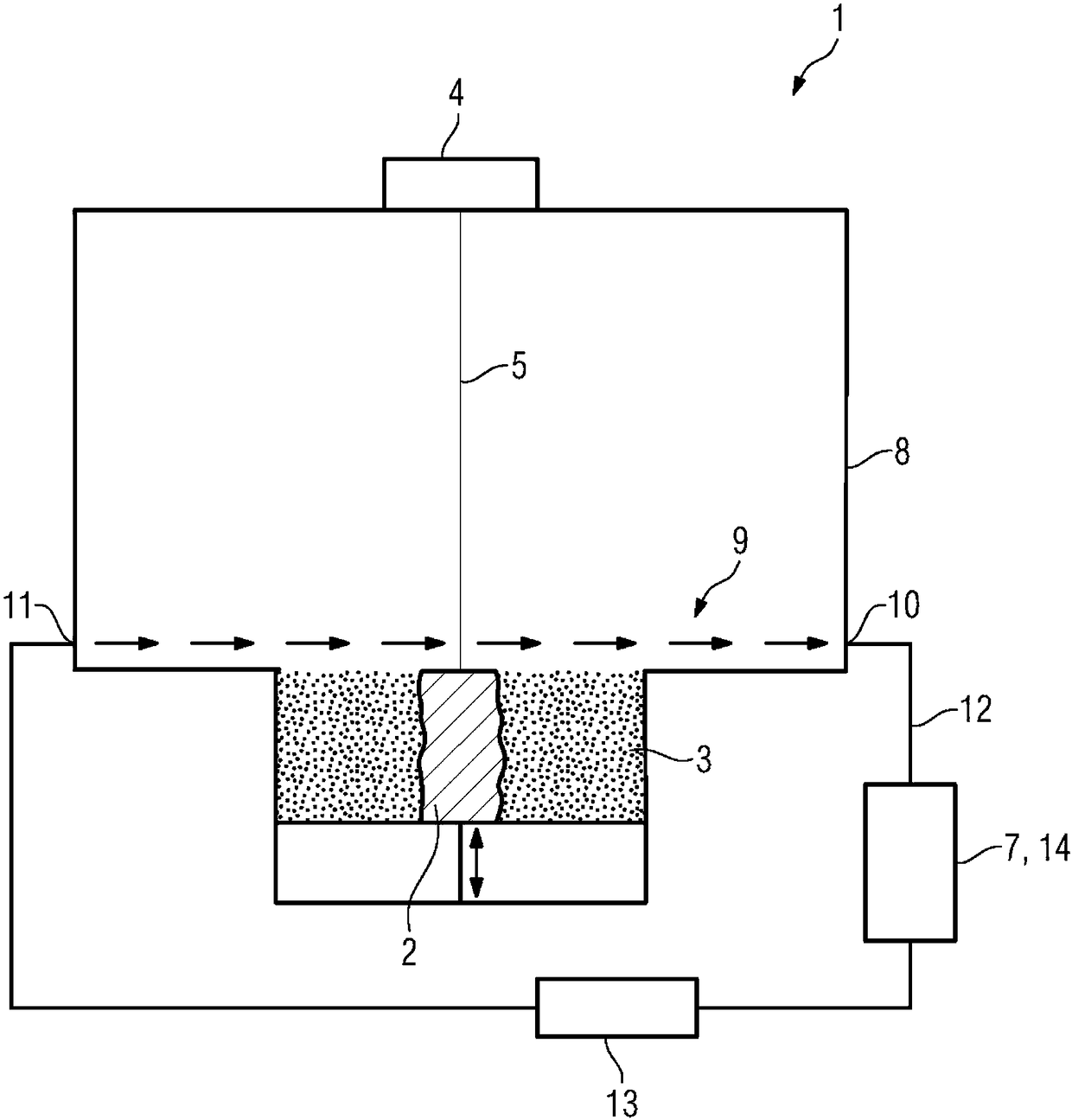

[0029] figure 1 A schematic diagram of a system 1 according to one embodiment is shown. exist figure 1 Only those partial parts of the system 1 that are relevant for explaining the principles described below are shown in the sectional view.

[0030] The system 1 is used for the additive production of layers of a build material 3 curable by means of a laser beam 5 , that is to say for example metal powder, by selectively irradiating and thus selectively curing layer by layer in succession. A three-dimensional object 2 , that is to say in particular a technical component or a group of technical components. The selective curing of the respective layer of construction material to be cured is carried out on the basis of object-related construction data. The corresponding construction data describe the geometrical or geometrical structural design of the object 2 to be additively produced in each case and may contain, for example, “scribed” CAD data of the object 2 to be produced....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com