Impurity filtering device with automatic back wash function and filtering method

A technology of impurity filtration and backwashing, applied in filtration separation, separation methods, gravity filters, etc., can solve the problems of inconvenient assembly and disassembly, time-consuming and laborious, and achieve the effect of reducing water consumption, enhancing effect, and saving assembly and disassembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

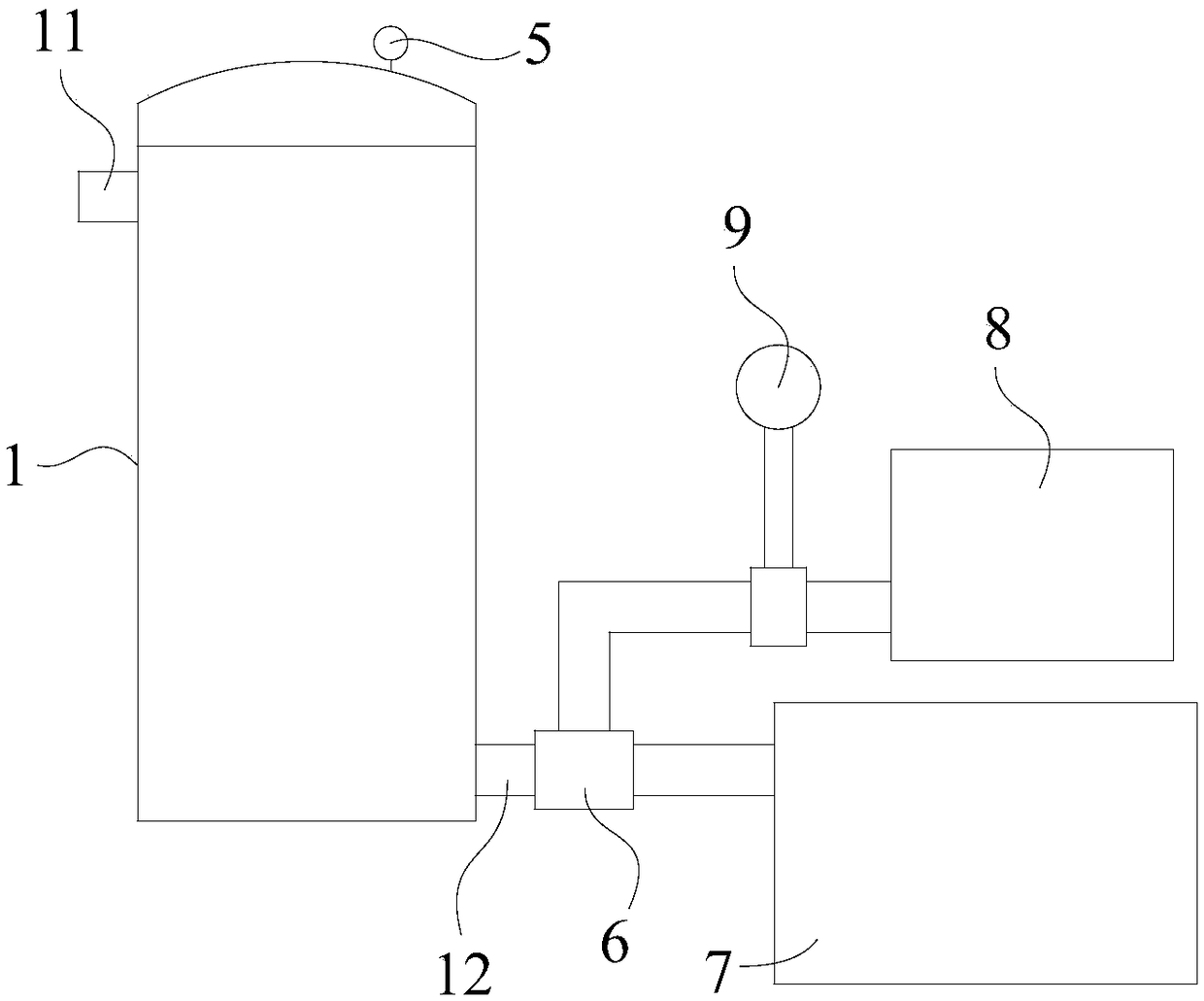

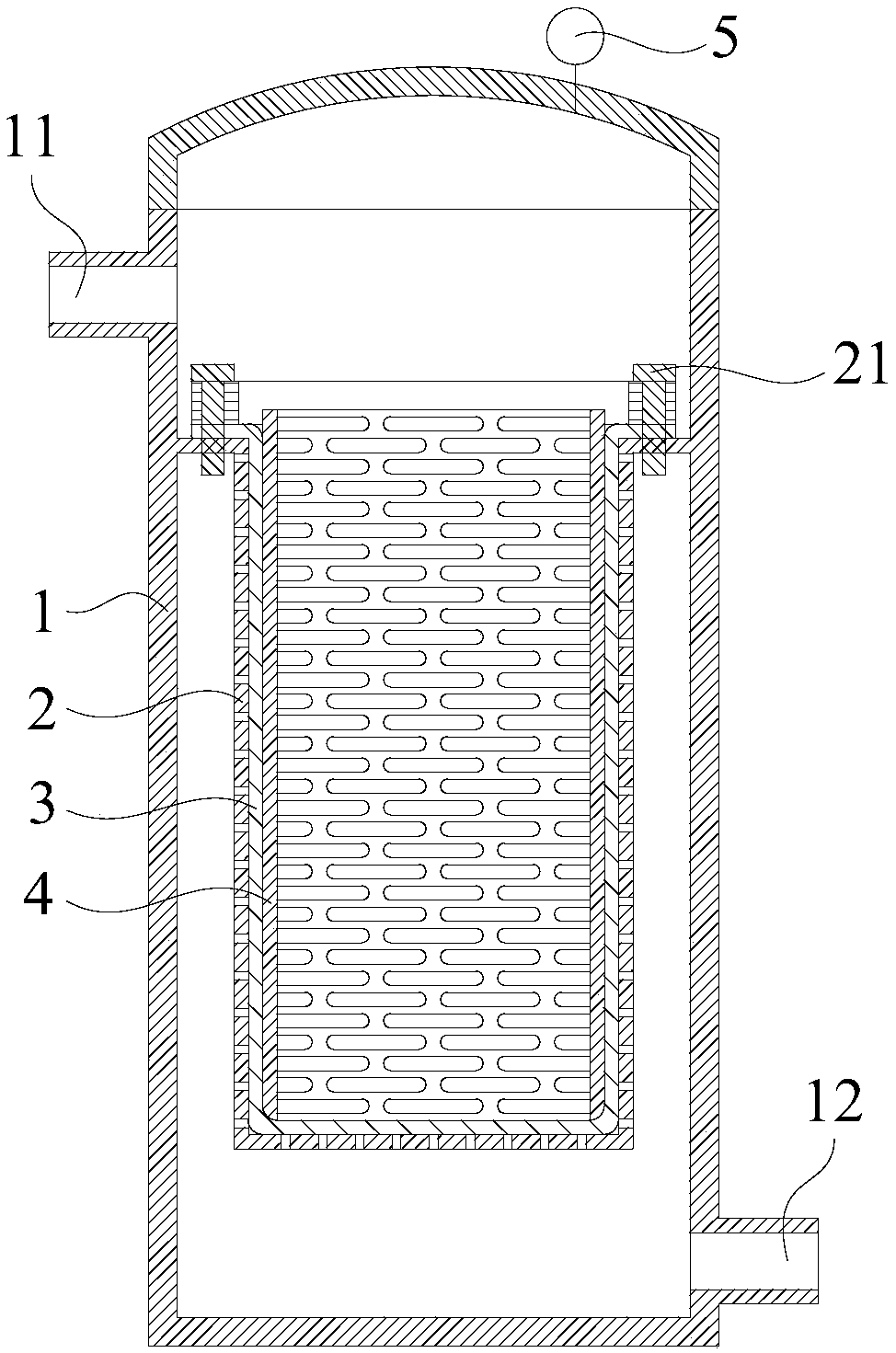

[0045] Such as Figure 1-2 As shown, an impurity filtering device with automatic backwashing according to the present invention includes a housing 1 and a control system.

[0046]The housing 1 is provided with a water inlet 11 and a water outlet 12, the housing 1 is provided with an installation bucket 2, and the installation bucket 2 is provided with several holes, and the water inlet 11 is located in the housing 1, the water outlet 12 is located at the lower end of the housing 1, the water outlet 12 is connected to the three-way valve 6, one end of the three-way valve 6 is connected to the water storage tank 7, and the other end is connected to the clean water source 8, the installation bucket A filter bag 3 is set inside the filter bag 3, and a support frame 4 is set inside the filter bag 3, and the support frame 4 supports and fits the filter bag 3 in the installation barrel 2, and the housing 1 There is a pressure detection part 5 on it, and the pressure detection part 5...

Embodiment 2

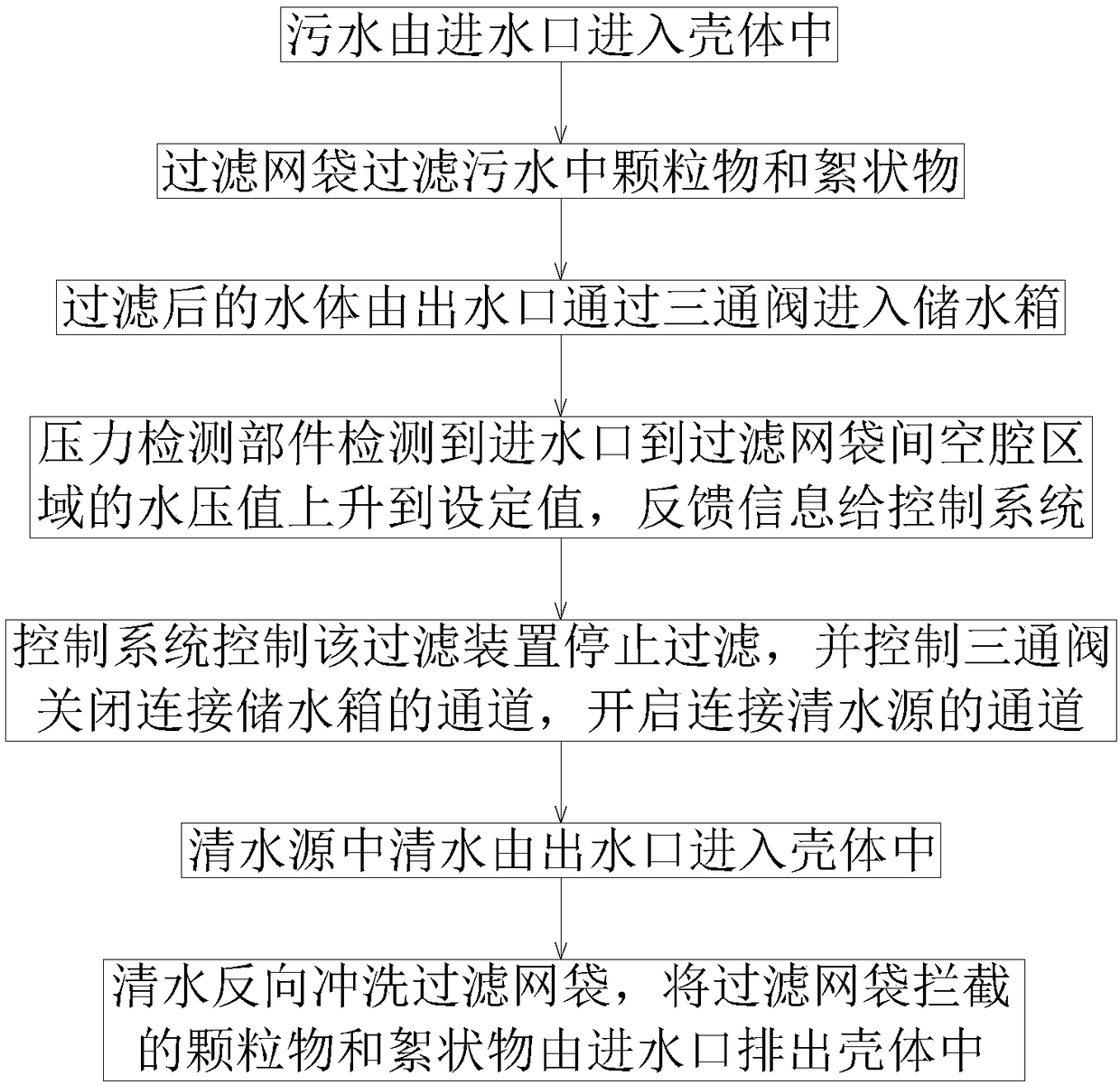

[0053] Such as Figure 1-3 As shown, a kind of filtering method of the impurity filtering device with automatic backwashing as described in embodiment 1 of the present invention comprises the following steps:

[0054] A. Sewage enters the casing 1 from the water inlet 11;

[0055] B, the filter bag 3 filters the particles and flocs in the sewage;

[0056] C. The filtered water enters the water storage tank 7 through the water outlet 12 through the three-way valve 6;

[0057] D. The pressure detection part 5 detects that the water pressure value in the cavity area between the water inlet 11 and the filter bag 3 rises to a set value, and feeds back information to the control system;

[0058] E. The control system controls the filtering device to stop filtering, and controls the three-way valve 6 to close the channel connected to the water storage tank 7, and open the channel connected to the clean water source 8;

[0059] F. The clean water in the clean water source 8 enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com