Ground mat heavy oil cleaning machine

A technology of oil stain cleaning and high-pressure washing, which is applied to carpet cleaning machines and machine parts, etc. It can solve the problems of easy deviation of floor mats, unstable transmission, and absorption of fluff at the end of floor mats, etc., so as to improve the service life and reduce cross-contamination , The effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

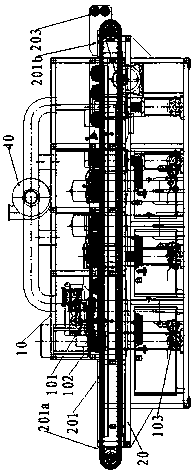

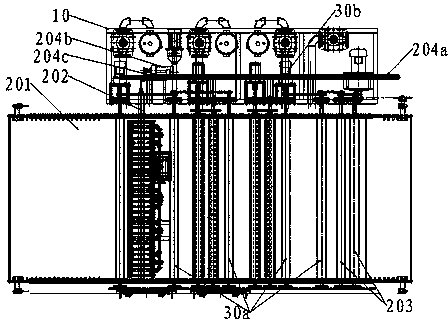

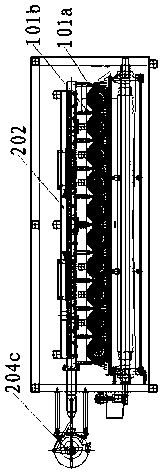

[0031] Such as figure 1 with figure 2 As shown, a floor mat heavy oil cleaning machine includes a rolling brush system 10 and a reciprocating mechanism 20, and the reciprocating mechanism 20 includes a transmission device 201, a moving frame 202 and an extruding dehydration device 203, and one end of the transmission device 201 is The upper material level 201a, the other end is the lower material level 202b, and the extrusion dehydration device 203 is located at the lower material level 201b of the transmission device 201; The transmission device 201 reciprocates in the axial direction and also moves back and forth perpendicularly to its axial direction; the roller brush system 10 includes a high-pressure flushing system 101, a low-pressure flushing system 102 and a spray pump 103, and the spray pump 103 passes through pipelines respectively Connect the high-pressure flushing system 101 and the low-pressure flushing system 102, the high-pressure flushing system 101 is fixed ...

Embodiment 2

[0033] Such as figure 1 with figure 2 As shown, a floor mat heavy oil cleaning machine includes a rolling brush system 10 and a reciprocating mechanism 20, and the reciprocating mechanism 20 includes a transmission device 201, a moving frame 202 and an extruding dehydration device 203, and one end of the transmission device 201 is The upper material level 201a, the other end is the lower material level 202b, and the extrusion dehydration device 203 is located at the lower material level 201b of the transmission device 201; The transmission device 201 reciprocates in the axial direction and also moves back and forth perpendicularly to its axial direction; the roller brush system 10 includes a high-pressure flushing system 101, a low-pressure flushing system 102 and a spray pump 103, and the spray pump 103 passes through pipelines respectively Connect the high-pressure flushing system 101 and the low-pressure flushing system 102, the high-pressure flushing system 101 is fixed ...

Embodiment 3

[0036] Such as figure 1 with figure 2As shown, a floor mat heavy oil cleaning machine includes a rolling brush system 10 and a reciprocating mechanism 20, and the reciprocating mechanism 20 includes a transmission device 201, a moving frame 202 and an extruding dehydration device 203, and one end of the transmission device 201 is The upper material level 201a, the other end is the lower material level 202b, and the extrusion dehydration device 203 is located at the lower material level 201b of the transmission device 201; The transmission device 201 reciprocates in the axial direction and also moves back and forth perpendicularly to its axial direction; the roller brush system 10 includes a high-pressure flushing system 101, a low-pressure flushing system 102 and a spray pump 103, and the spray pump 103 passes through pipelines respectively Connect the high-pressure flushing system 101 and the low-pressure flushing system 102, the high-pressure flushing system 101 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com