Ready-to-eat shredded bacon food and processing technology thereof

A processing technology and technology of shredded bacon, applied in the field of ready-to-eat shredded bacon food and its processing technology, can solve the problems of inconvenience to carry, adverse to physical health, restricting the consumption and promotion of bacon products, etc. delicious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

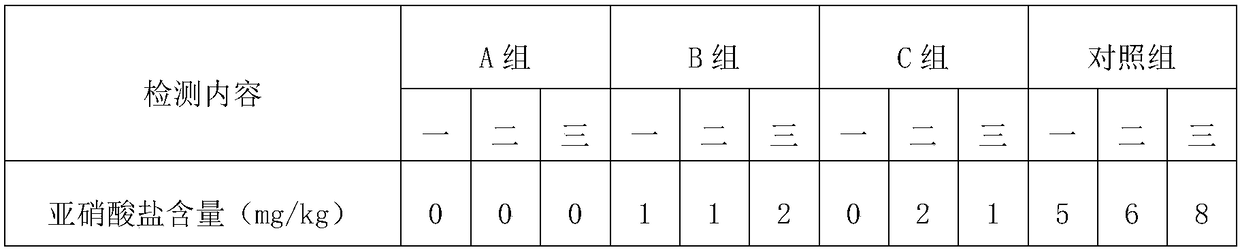

[0026] 1) Raw material preparation: wash and cut the low-nitrite bacon into uniform filaments, 4-6cm long, 0.8-1.5cm wide, and 0.4-0.8cm thick; mix the bacon with licorice, tangerine peel, wolfberry and white radish Put it in water and boil it, add 25g of licorice, 10g of tangerine peel, 12g of wolfberry, and 60g of white radish for every 1kg of shredded bacon, boil for 50min, then remove and drain for later use;

[0027] 2) Preparation of ingredients: by weight, take 4 parts of white sugar, 4 parts of salt, 5 parts of minced ginger, 5 parts of pepper, 3 parts of pepper oil, 12 parts of sesame, 1 part of chicken essence, 2 parts of rice vinegar and 30 parts of cooking oil for later use;

[0028] 3) Seasoning: Pour the edible oil into the pot and heat it up, add minced ginger, sesame and chili to the hot oil and blanch for 1 minute, then pour the hot oil with minced ginger, sesame and chili on the shredded bacon, then add white sugar , salt, chicken essence, pepper oil and rice...

Embodiment 2

[0031] 1) Raw material preparation: wash and cut the low-nitrite bacon into uniform filaments, 4-6cm long, 0.8-1.5cm wide, and 0.4-0.8cm thick; mix the bacon with licorice, tangerine peel, wolfberry and white radish Put it in water and boil it, add 20g of licorice, 8g of tangerine peel, 10g of wolfberry, and 50g of white radish for every 1kg of shredded bacon, boil for 45 minutes, then remove and drain for later use;

[0032] 2) Preparation of ingredients: by weight, take 3 parts of white sugar, 3 parts of salt, 4 parts of minced ginger, 2 parts of pepper, 2 parts of pepper oil, 10 parts of sesame, 1 part of chicken essence, 2 parts of rice vinegar and 25 parts of cooking oil for later use;

[0033] 3) Seasoning: Pour the edible oil into the pot and heat it up, add minced ginger, sesame and chili to the hot oil and blanch for 1 minute, then pour the hot oil with minced ginger, sesame and chili on the shredded bacon, then add white sugar , salt, chicken essence, pepper oil and ...

Embodiment 3

[0036] 1) Raw material preparation: wash and cut the low-nitrite bacon into uniform filaments, 4-6cm long, 0.8-1.5cm wide, and 0.4-0.8cm thick; mix the bacon with licorice, tangerine peel, wolfberry and white radish Put it in water and boil it, add licorice 30g, tangerine peel 12g, wolfberry 15g, white radish 80g for every 1kg bacon shreds, cook for 55min, then remove and drain for later use;

[0037] 2) Preparation of ingredients: by weight, take 5 parts of white sugar, 5 parts of salt, 6 parts of minced ginger, 6 parts of pepper, 4 parts of pepper oil, 15 parts of sesame, 2 parts of chicken essence, 3 parts of rice vinegar and 35 parts of cooking oil for later use;

[0038] 3) Seasoning: Pour the edible oil into the pot and heat it, then add minced ginger, sesame and chili to the hot oil and blanch for 2 minutes, then pour the hot oil with minced ginger, sesame and chili on the shredded bacon, then add white sugar , salt, chicken essence, pepper oil and rice vinegar, mix wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com