Manufacturing method of Chinese plum whole fruit juice drink

A manufacturing method and juice technology, which are applied in the manufacturing field of pure natural fruit juice beverages, can solve the problems of small fresh food market, sour and astringent fruits, etc., and achieve the effects of adjusting the acidity of juice, avoiding degradation, and reducing the loss of flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

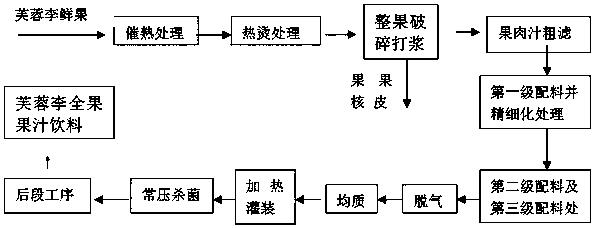

[0042] A kind of manufacture method of hibiscus plum whole fruit juice drink, its technological process comprises the following steps:

[0043] A. Ripening of Hibiscus plum fruits: first manually remove the fruits of diseases and insect pests, mechanically damaged fruits and sun-burned fruits of the freshly picked Hibiscus plum fruits, put the qualified fruits into the turnover box, soak them in 1000ppm ethephon solution for 2 minutes, put them in Accelerate ripening in room temperature warehouse for 5-7 days, when more than 90% of fruit hardness is lower than 1kg / cm 2 ready for processing;

[0044] B. Blanching treatment: first rinse the ripened fruit, and then scald it in 100ºC hot water for 4 minutes;

[0045] C. Whole fruit crushing and beating: Pour the blanched fruit into the spiral crushing and beating machine for whole fruit crushing and beating, one side produces pulp juice, and the other side automatically discharges the peel and core (the diameter of the stainless ...

Embodiment 2

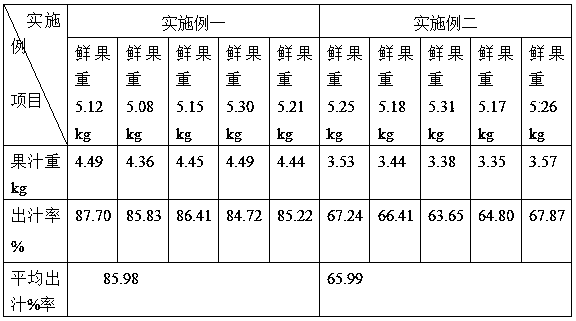

[0071] A method for manufacturing a fruit juice drink with plum pulp, the process steps of which are the same as those in Example 1, the difference being that the fruit of the plum fruit is not subjected to ripening and blanching treatment, and the juice is directly squeezed from the naturally ripe fruit, and the juice yield is greatly reduced , see Table 1 for specific data.

[0072] Table 1 Comparison of juice yield between accelerated ripening and natural ripening of Furong plum fruit

[0073]

Embodiment 3 Embodiment 4

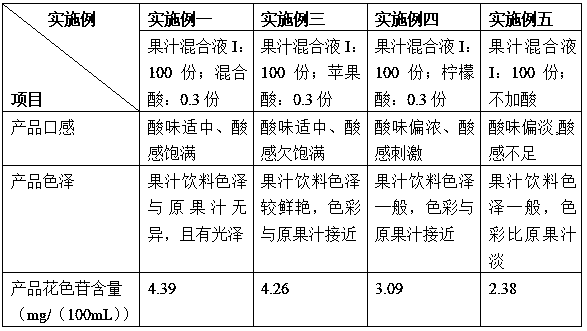

[0075] A kind of manufacture method of hibiscus plum fruit juice beverage, its technological process step is the same as embodiment one, and difference is:

[0076] The mixed-type color-protecting agent in the first-level compounding process can also not use a mixed-type acid color-protecting agent, but only a certain acid or no acid in the above-mentioned mixed-type acid color-protecting agent, which is important for preventing anthocyanin The degradation, color protection effect and mouthfeel will become worse.

[0077] Table 2 Comparison table of color protection effect and anthocyanin content of different color protection agents

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com