Infrared, laser and microwave low detectability compatible sub-wavelength structural material

A sub-wavelength structure and laser technology, which is applied in optics, optical components, antennas, etc., can solve the problems of low detectability and mutual compatibility, and achieve the effects of light and thin structure, expanded application range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

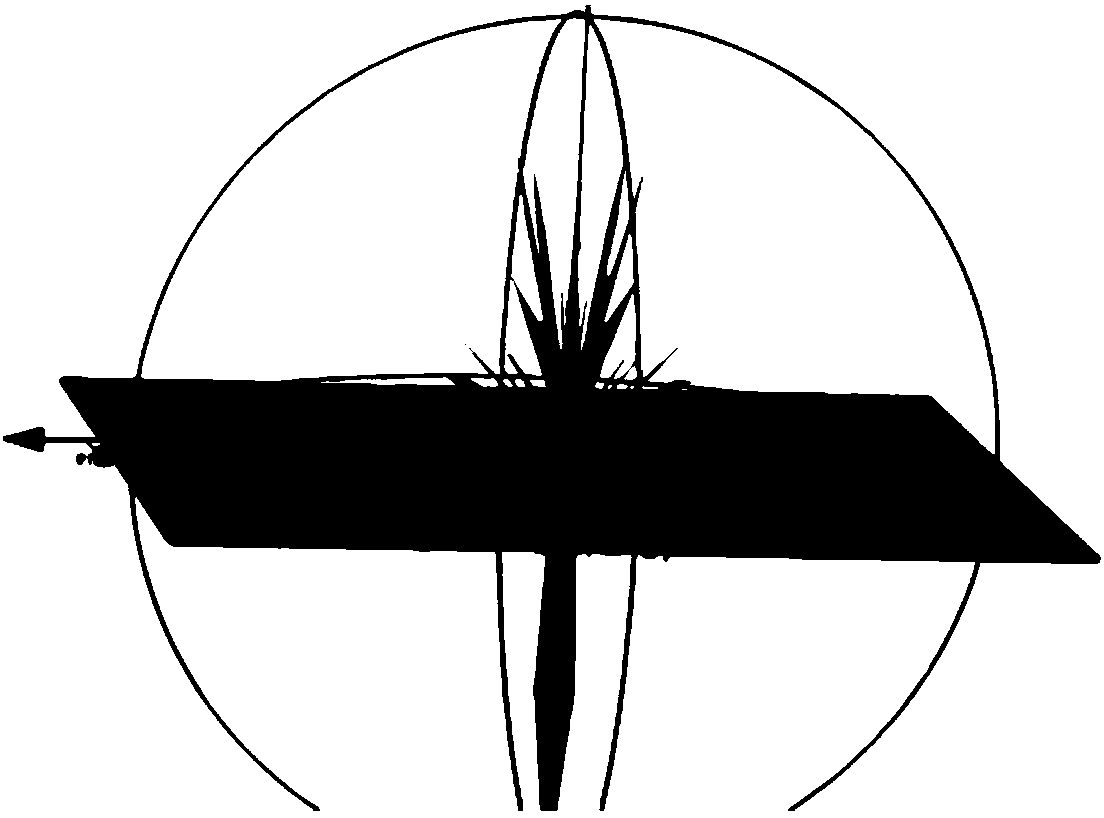

[0022] A sub-wavelength structural material compatible with infrared, laser and microwave low detectability of the present invention, such as figure 1 As shown, the subwavelength structure material sequentially includes a metal-type frequency selective surface layer I, a dielectric layer I, a metal-type frequency selective surface layer II, a dielectric layer II, a resistive film and a dielectric layer III from top to bottom. The specific structural parameter values are shown in Table 2 below.

[0023] Table 2 The structural parameter values of the infrared, laser and microwave low detectability compatible sub-wavelength structural materials of Example 1

[0024]

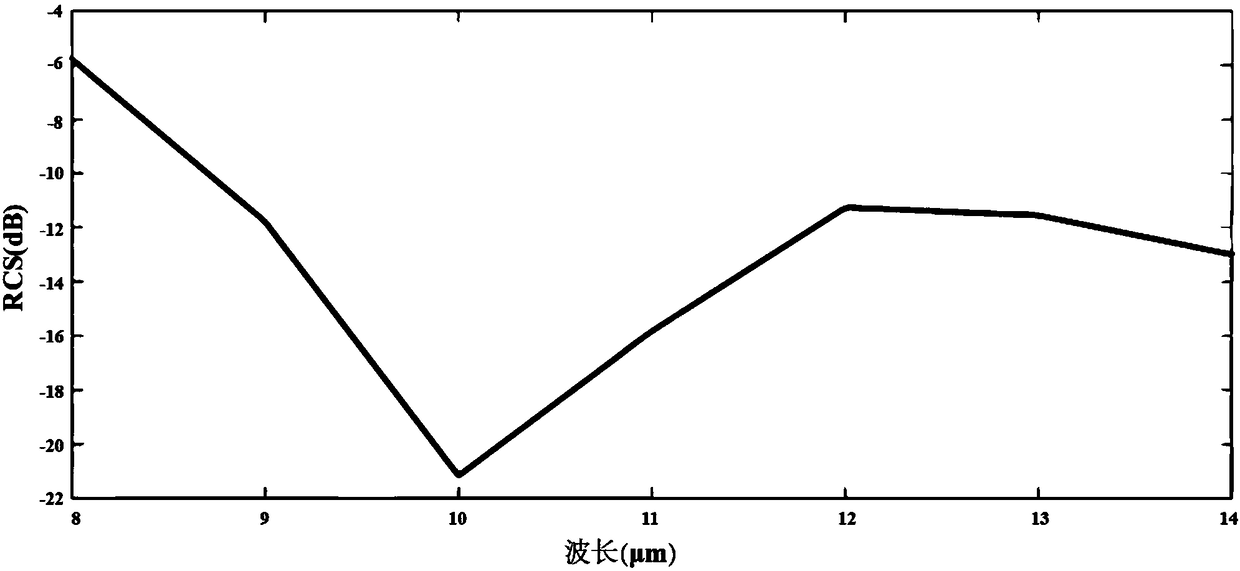

[0025] This embodiment proves the low detectability effect of the present invention on infrared and laser through far-field scattering and RCS reduction, and proves the absorbing effect on microwave through reflectivity. figure 2 It is the far-field scattering diagram of the present invention when the laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com