Preparation method of electro-deposited hydroxyapatite in choline chloride based ionic liquid

A choline chloride and ionic liquid technology, applied in the field of biomedical materials, can solve the problems of difficulty in providing hydroxyl groups, restrictions, etc., and achieve the effects of reducing hydrogen evolution, improving density, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Method for preparing HA coating by ultrasonic-pulse electrodeposition in choline chloride-urea ionic liquid

[0020] Weigh 50 g of dried choline chloride and 72 g of urea, and control the temperature in an oil bath at 80°C to prepare a colorless and uniform choline chloride-urea ionic liquid, and then add CaCl 2 and NH 4 h 2 PO 4 Further dissolves, regulates Ca 2+ The concentration is 10 mmol∙L -1 , H 2 PO 4 2- The concentration is 6 mmol∙L -1 , join H 2 o 2 3 mL, adjust the pH of the solution to 4.6, and complete the preparation of the electrodeposition solution.

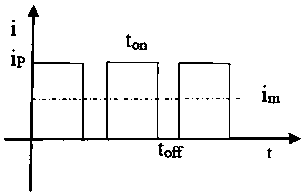

[0021] Under the composition of the above electrodeposition solution, the temperature of the solution is controlled at 80°C, the ultrasonic power is 300 W, and the ultrasonic frequency is 80kHz. The HA coating is prepared by unidirectional positive pulse electrodeposition. The pulse electrodeposition waveform is as attached figure 1 As shown, the pulse average current density is 5mA∙cm -2 , with ...

Embodiment 2

[0023] Method for preparing HA coating by ultrasonic-pulse electrodeposition in choline chloride-ethylene glycol ionic liquid

[0024] Weigh 60 g of dried choline chloride and 80 g of ethylene glycol, and control the temperature in an oil bath at 90°C to prepare a colorless and uniform choline chloride-ethylene glycol ionic liquid, and then add CaCl 2 and NaH 2 PO 4 Further dissolves, regulates Ca 2+ The concentration is 10 mmol∙L -1 , H 2 PO 4 2- The concentration is 5.5 mmol∙L -1 , join H2 o 2 2 mL, adjust the pH of the solution to 4.8, and complete the preparation of the electrodeposition solution.

[0025] Under the above electrodeposition solution composition, the temperature of the solution was controlled at 90 °C, the ultrasonic power was 200 W, and the ultrasonic frequency was 100 kHz. The HA coating was prepared by unidirectional positive pulse electrodeposition, and the pulse average current density was 4 mA∙ cm -2 , with a turn-on time of 8 s, a turn-off t...

Embodiment 3

[0027] Method for preparing HA coating by ultrasonic-pulse electrodeposition in choline chloride-glycerol ionic liquid

[0028] Weigh 80 g of dried choline chloride and 100 g of glycerol, and control the temperature in an oil bath at 90°C to prepare a colorless and uniform choline chloride-glycerol ionic liquid, and then add Ca(NO 3 ) 2 and NH 4 h 2 PO 4 Further dissolves, regulates Ca 2+ The concentration is 15mmol∙L -1 , H 2 PO 4 2- The concentration is 8 mmol∙L -1 , join H 2 o 2 4 mL, adjust the pH of the solution to 5.5, and complete the preparation of the electrodeposition solution.

[0029] Under the above electrodeposition solution composition, the temperature of the solution was controlled at 90 °C, the ultrasonic power was 300 W, and the ultrasonic frequency was 60 kHz. The HA coating was prepared by unidirectional positive pulse electrodeposition, and the pulse average current density was 10 mA∙ cm -2 , with a turn-on time of 12 s, a turn-off time of 6 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com