Montelukast sodium granules and preparation method thereof

A technology of montelukast sodium and granules, applied in the field of montelukast sodium granules and its preparation, can solve problems such as poor control of drying temperature, migration of soluble components, poor tablet stability, etc., and achieve convenient and comfortable taking. , Improve stability, and show rapid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

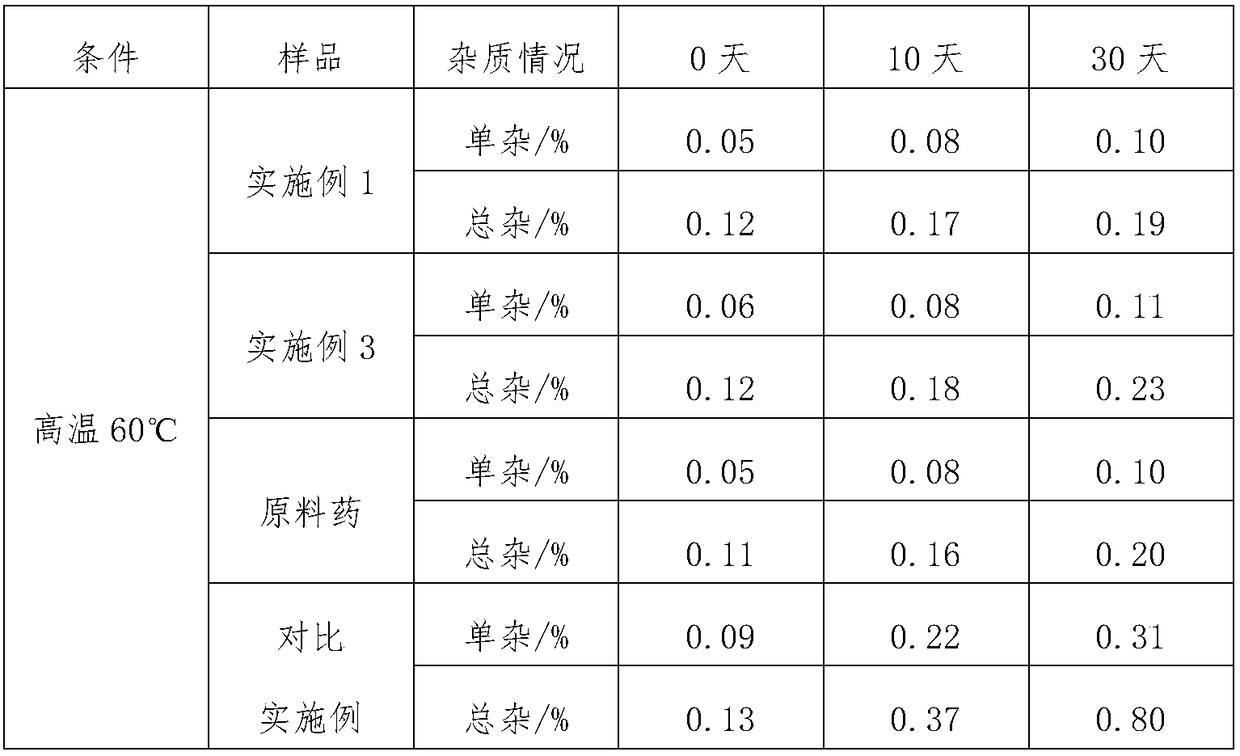

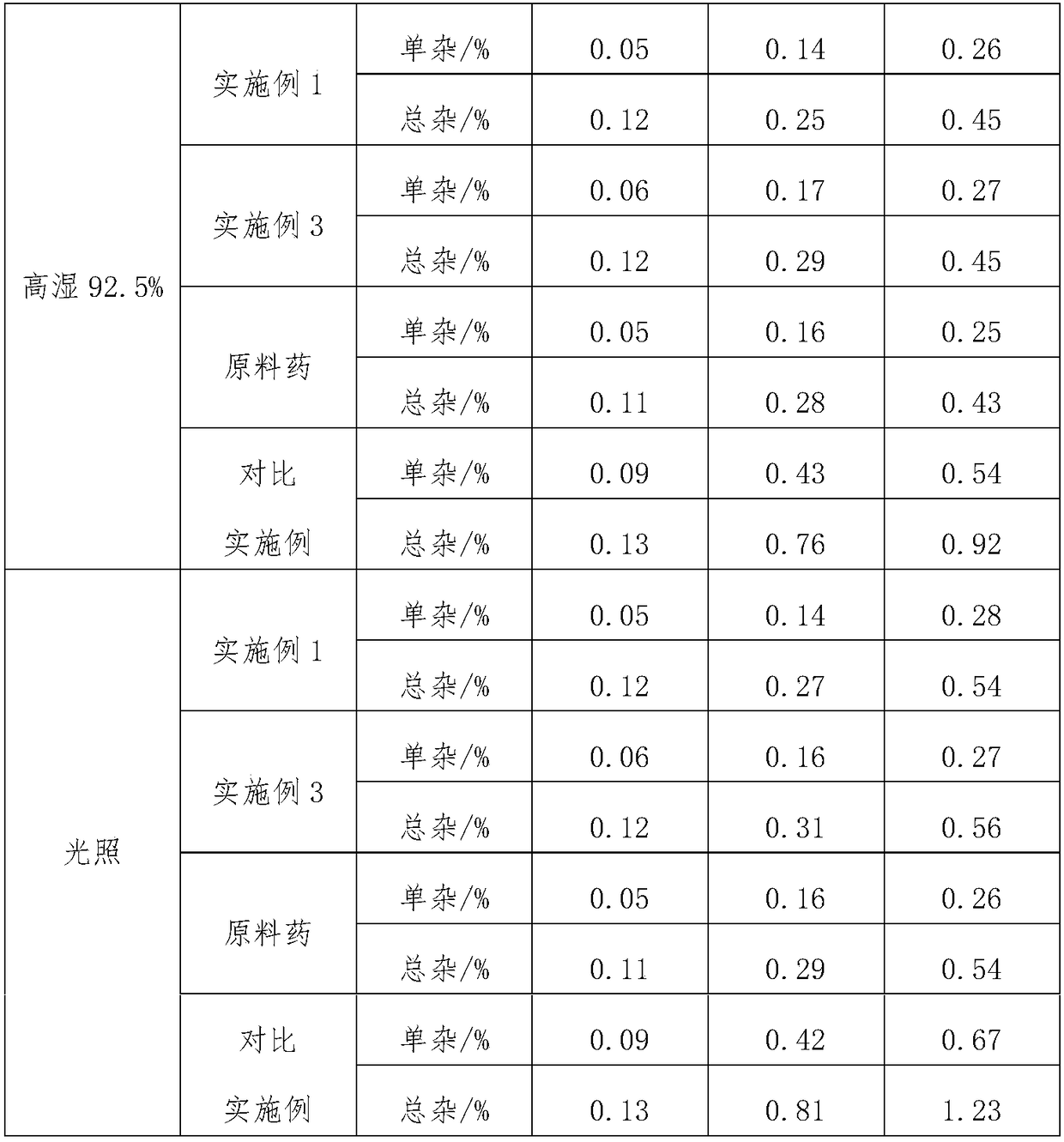

Examples

Embodiment 1

[0043] The Montelukast sodium granules provided in this embodiment are prepared by dry granulation of raw materials. In terms of weight percentage, the raw materials include the following ingredients:

[0044] Montelus Turner 0.5%,

[0045] Mannitol 35%,

[0046] Anhydrous Lactose 43.5%,

[0047] Microcrystalline Cellulose 20%,

[0048] Flavoring agent 0.5%,

[0049] Lubricant 0.5%.

[0050] Wherein, the flavoring agent is cyclamate, and the lubricant is magnesium stearate.

[0051] Preparation method: take montelukastina and anhydrous lactose according to the formula and pass through a 100-mesh sieve respectively, and mix evenly; take mannitol, microcrystalline cellulose and flavoring agent and pass through a 80-mesh sieve respectively, and then mix with montelukast The mixture of sodium and anhydrous lactose is mixed evenly; put the total mixture in a dry granulator, set the parameters, the pressure is 20Mpa, the motor speed is 30rpm, adjust the mesh size of the whole m...

Embodiment 2

[0054] The Montelukast sodium granules provided in this example are prepared from raw materials by dry granulation, and the ingredients of the raw materials are the same as those in Example 1.

[0055]Preparation method: take montelukastina and anhydrous lactose according to the formula and pass through a 100-mesh sieve respectively, and mix evenly; take mannitol, microcrystalline cellulose and flavoring agent and pass through a 80-mesh sieve respectively, and then mix with montelukast The mixture of sodium and anhydrous lactose is mixed evenly; put the total mixture in a dry granulator, set the parameters, the pressure is 2Mpa, the motor speed is 30rpm, adjust the mesh size of the whole material screen, so that the particle size reaches 10 mesh, and add lubricant , Determining the content of intermediates; adding the prepared granules into the hopper of the granule filling machine, adjusting the sub-metering device, setting the volume of each package to 0.5g, and sub-packing t...

Embodiment 3

[0058] The Montelukast sodium granules provided in this embodiment are prepared by fluidized bed granulation of the raw materials, and the raw materials include the following components by weight percentage:

[0059] Montelus Turner 0.5%,

[0060] Mannitol 35%,

[0061] Anhydrous Lactose 43.5%,

[0062] Microcrystalline Cellulose 20%,

[0063] Binder 2%

[0064] Flavoring agent 0.5%,

[0065] Lubricant 0.5%.

[0066] Wherein, the flavoring agent is cyclamate, and the lubricant is magnesium stearate.

[0067] Preparation:

[0068] Pass raw materials such as montelukast sodium, anhydrous lactose, mannitol, microcrystalline cellulose, flavoring agent and other auxiliary materials through a 100-mesh sieve, and mix evenly; suck the total mixed material into the fluidized bed, and spray it with top spray, Use absolute ethanol as the binder, set the spray speed to 1.5ml / min, the blast speed to 3L / min, and the heating temperature to 20°C, so that the moisture content of the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com