Melting equipment for melting and casting aluminum rods for aluminum profiles

A technology for smelting equipment and aluminum profiles, which is used in foundry equipment, equipment for feeding molten metal into molds, and metal processing equipment, which can solve problems affecting the purity, smoothness and strength of aluminum profiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

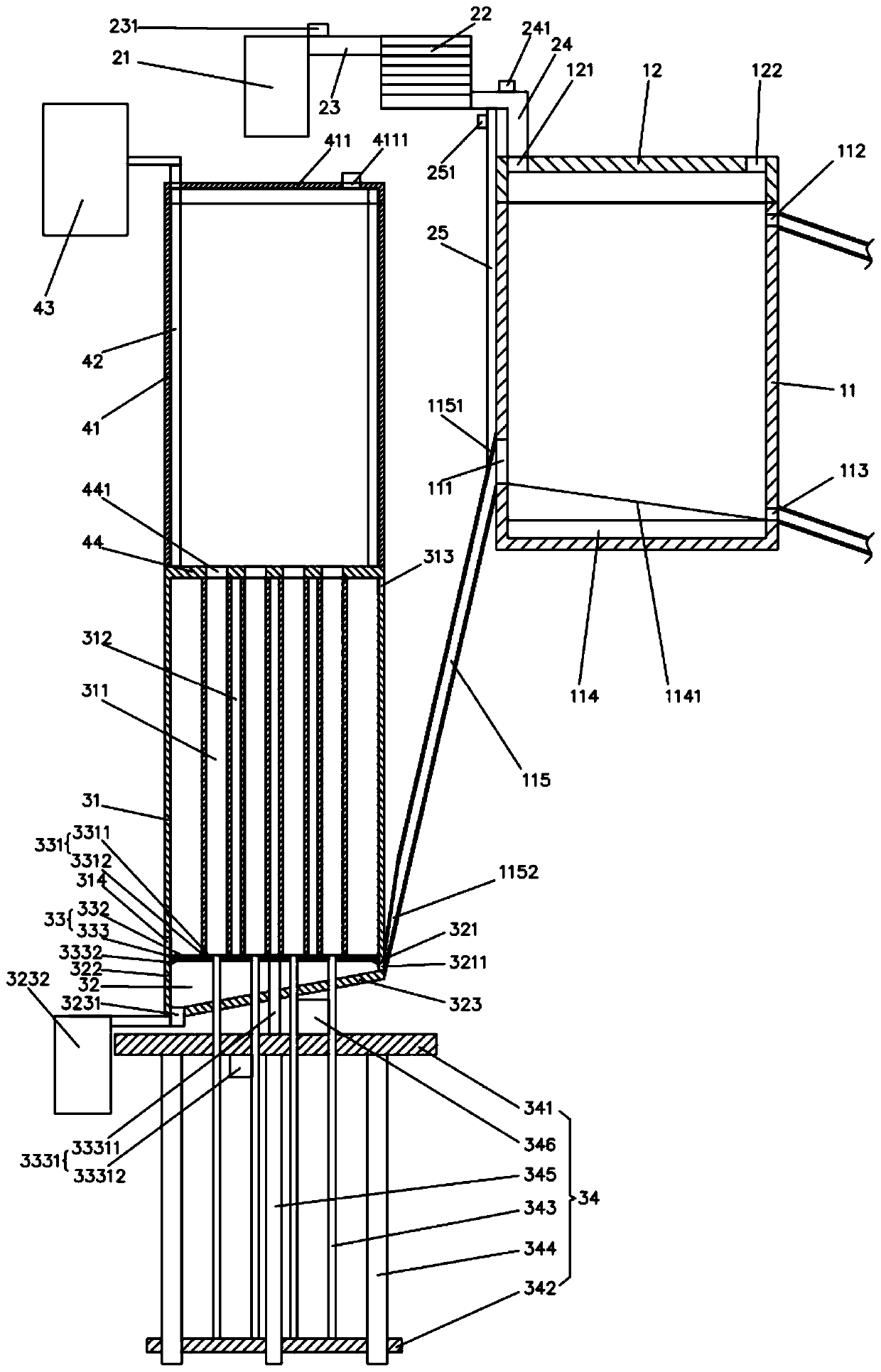

[0032] A kind of smelting equipment for melting and casting aluminum rods for aluminum profiles of the present invention, such as figure 1 As shown, it includes a melting furnace; it also includes a nitrogen blowing device, an aluminum rod casting device and an anti-oxidation spraying device;

[0033] The smelting furnace includes a furnace body 1 and a furnace cover 12 arranged on the upper opening of the furnace body 1; the side wall of the furnace body 1 is formed with a first outlet 111 for molten aluminum to flow out for casting, and the height of the first outlet 111 is higher than that of the first outlet 111 for melting aluminum The second outlet 112 that the surface layer of the liquid flows out, and the third outlet 113 that is lower than the first outlet 111 height for the bottom of the molten aluminum to flow out; The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com