Rice husk ash concrete and preparation method thereof

A rice husk ash and concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of difficult transportation, high cost of high-performance concrete, and high cost, and achieve good toughness and compressive strength. Improve the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

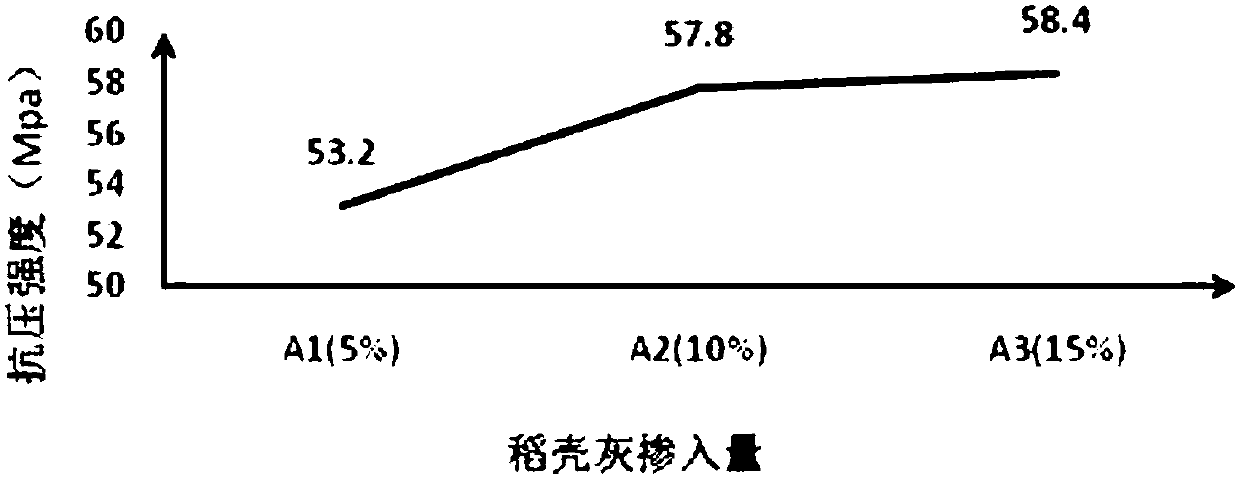

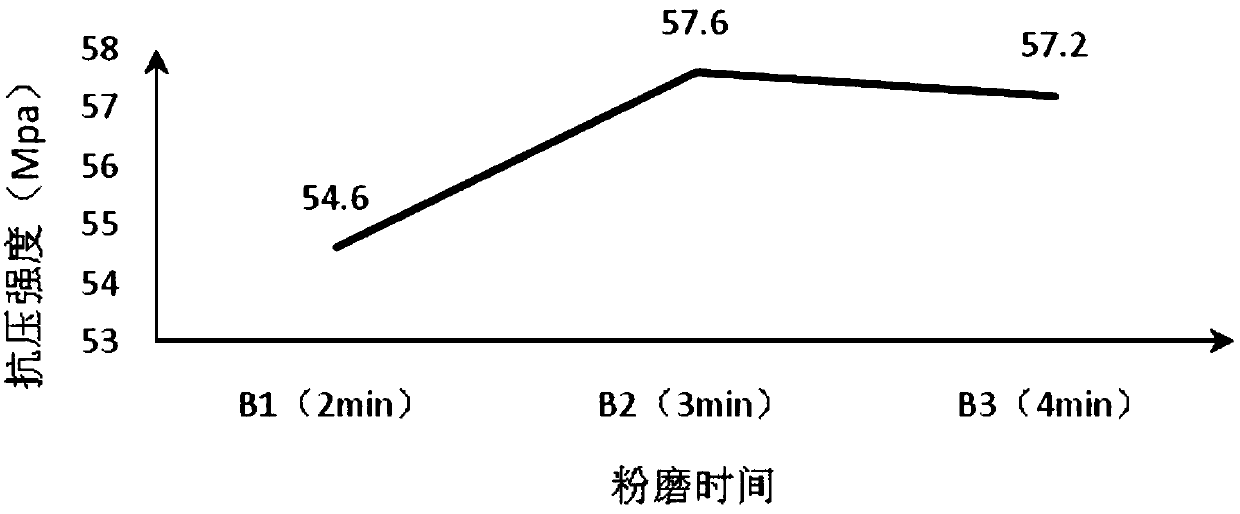

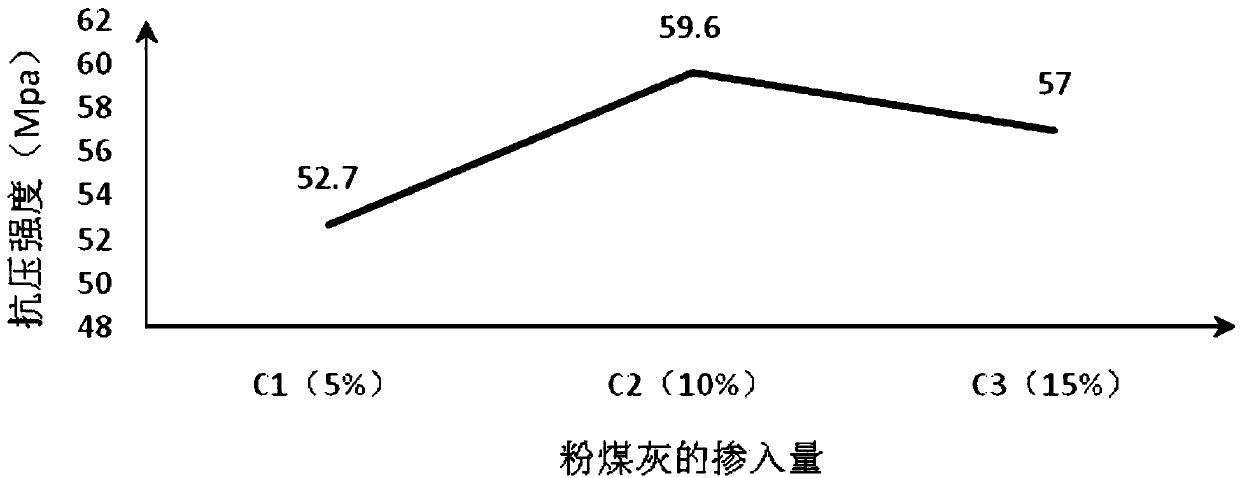

[0048] Embodiment 1-9 The ratio of 9 kinds of raw material components of the rice husk ash concrete of this application is shown in Table 4

[0049] Chemical composition (%) of table 2 silica fume

[0050]

[0051] Chemical composition (%) of table 3 rice husk ash

[0052]

[0053] Table 4 Consumption of each material in rice husk ash concrete (kg / m 3 )

[0054]

[0055] The YES-2000 and YAW-300 electro-hydraulic pressure testing machines manufactured by Jinan Zhongluchang Testing Machine Manufacturing Co., Ltd. were shipped in June 2015. The accuracy level is level 1, and the test readings are carried out by the RFP-03 intelligent tester. In this test, the former is used to test the compressive strength of concrete; the latter is used to test the splitting strength of concrete.

[0056] YH-40B standard constant temperature and humidity curing box. Produced by Beijing CCCC Engineering Instrument Research Institute, the maximum power is 2000W, and the working volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com