A method for producing tsr9710 rubber with standard rubber as raw material

A standard rubber and rubber technology, applied in the field of rubber processing, can solve the problems of customer quality complaints, product quality impact, difficult detection requirements, etc., to achieve good index stability, better quality control, and meet customer needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

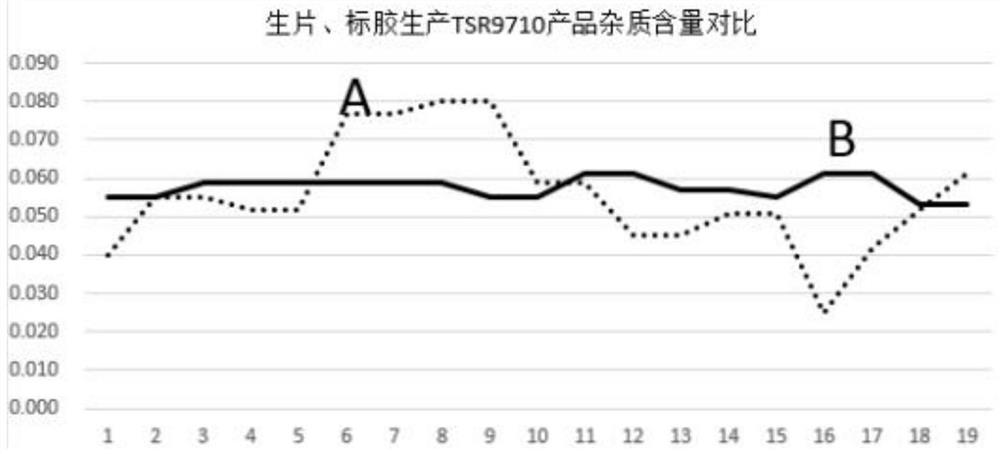

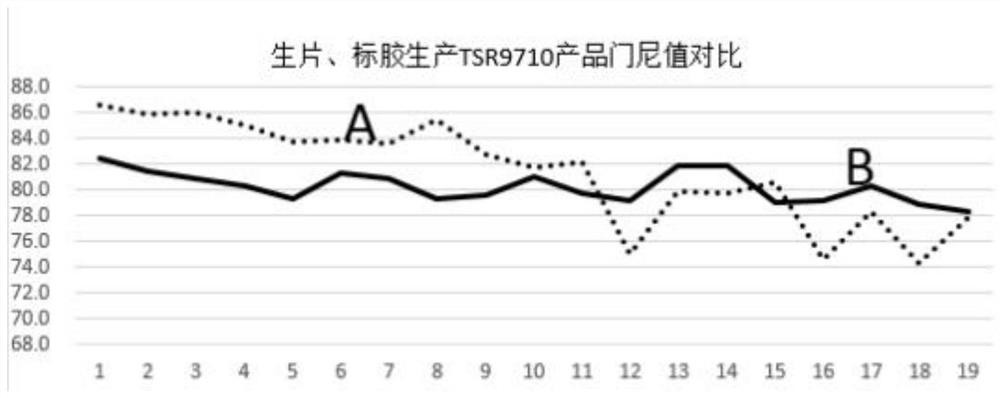

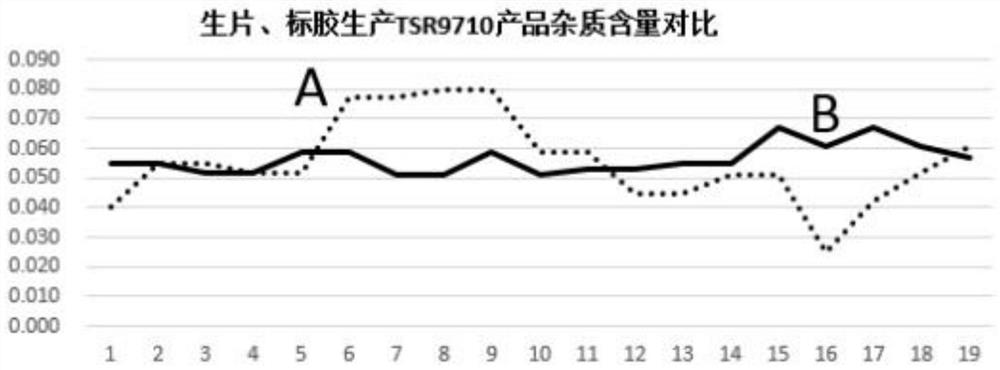

[0032] A kind of method that is raw material production TSR9710 rubber with standard rubber, comprises the following steps:

[0033] (1) Cut 37 tons of standard rubber TSR5, 15 tons of standard rubber TSR10, and 3 tons of standard rubber TSR20 into 2250-4500cm each 3 The rubber block is mixed again to obtain a mixed standard rubber; among them: the impurity of TSR5 is 0.04, and the Mooney value is 88; the impurity of TSR10 is 0.09, and the Mooney value is 65; the impurity of TSR20 is 0.16, and the Mooney value is 55 ;

[0034] (2) Put the mixed standard glue on the conveyor belt, transport it to the dry mixer, crush, squeeze, and shear, and obtain the rubber particles with a diameter of 3 cm; Wash for 30s, soak and float in the small round pool for 30s;

[0035] (3) Elevate the float-washed rubber particles by the bucket elevator, wash off the soaked and loose sediment on the surface of the rubber particles, and drip the rinsed rubber particles for 10 seconds;

[0036] (4) ...

Embodiment 2

[0045] A kind of method that is raw material production TSR9710 rubber with standard rubber, comprises the following steps:

[0046] (1) Cut 33 tons of standard rubber TSR5 and 22 tons of standard rubber TSR10 evenly into 2250-4500cm each 3 The rubber blocks were mixed again to obtain a mixed standard rubber; wherein: the impurity of TSR5 was 0.04, and the Mooney value was 95; the impurity of TSR10 was 0.06, and the Mooney value was 78;

[0047] (2) Place the mixed standard glue on the conveyor belt, transport it to the dry mixer, crush, squeeze, and shear to obtain rubber particles with a diameter of 4 cm; Wash for 60s, soak and float in the small round pool for 45s;

[0048] (3) Elevate the float-washed rubber particles through the bucket elevator, wash off the soaked and loose sediment on the surface of the rubber particles, and drip the rinsed rubber particles for 30 seconds;

[0049] (4) Transport the rubber particles to a double-roller machine for crushing and mixing, ...

Embodiment 3

[0058] A kind of method that is raw material production TSR9710 rubber with standard rubber, comprises the following steps:

[0059] (1) Cut 30 tons of standard rubber TSR5, 12 tons of standard rubber TSR10, and 13 tons of standard rubber TSR20 into 2250-4500cm each 3 The rubber block is mixed again to obtain a mixed standard rubber; among them: the impurity of TSR5 is 0.04, and the Mooney value is 88; the impurity of TSR10 is 0.09, and the Mooney value is 65; the impurity of TSR20 is 0.16, and the Mooney value is 55 ;

[0060] (2) Put the mixed standard glue on the conveyor belt, transport it to the dry mixer, crush, squeeze, and shear, and obtain the rubber particles with a diameter of 3 cm; Wash for 40s, soak and float in the small round pool for 50s;

[0061] (3) Elevate the float-washed rubber particles by the bucket elevator, wash off the soaked and loose sediment on the surface of the rubber particles, and drip the rinsed rubber particles for 20 seconds;

[0062] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com