A turbulent jet coupled integrated flue gas purification process for complex and difficult-to-treat flue gas

A flue gas purification process and difficult-to-handle technology, which is applied in the direction of gas treatment, combined devices, chemical instruments and methods, etc., can solve difficult problems and achieve the effects of high purification intensity, low investment, and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

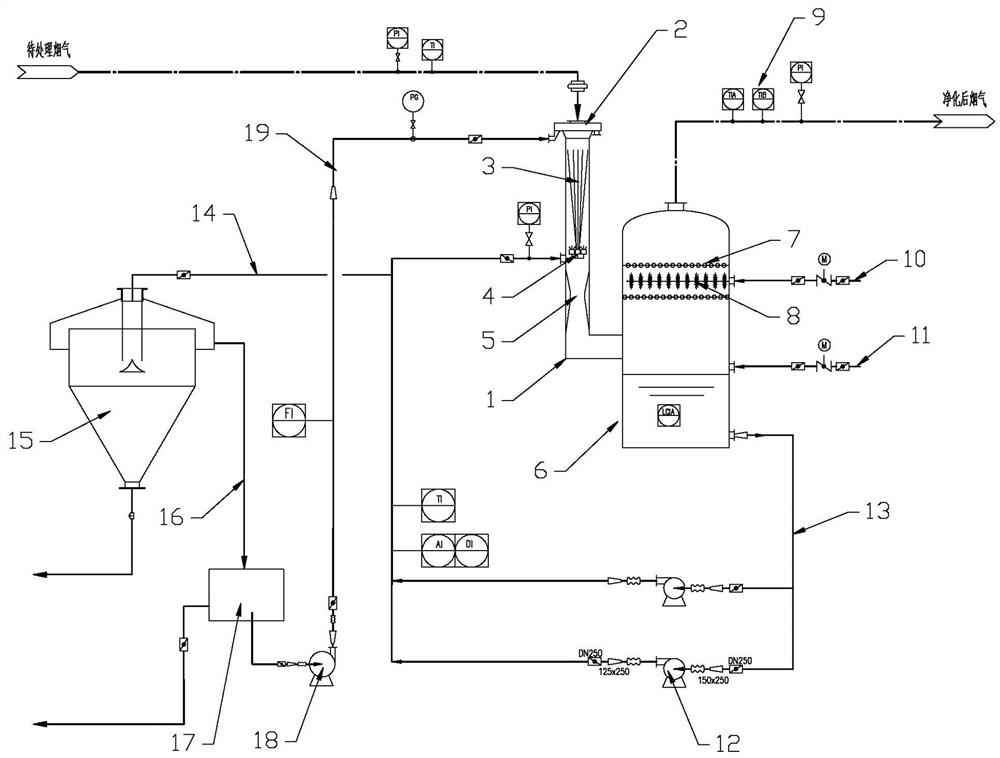

[0035] A Kaldor furnace processes 5,000 tons of precious metal anode slime per year, and the flue gas volume is 7,000-10,000m 3 / h, the flue gas contains 15g / m of powder such as lead oxide, selenium oxide, and Glauber's salt 3 ~40g / m 3 , the flue gas inlet temperature is 300-600°C, the SO in the flue gas 2 Content 31500mg / Nm 3 And a small amount of HF, HCl, NOx, H 2 Se, etc. need to be purified and absorbed. The annular overflow weir 2 is equipped with a water curtain to protect the inner wall of the smoke pipe. The high-temperature flue gas enters the turbulent washing section 3 through the annular overflow weir 2, where it is sprayed with the washing and absorbing liquid sent by the circulating pump 12 through the large-opening turbulent nozzle 4. The flue gas and the washing and absorbing liquid form a suspended dynamic foam area, where the gas-liquid two-phase contact is intense to complete the adsorption absorption and adiabatic evaporation process, and the gas-liquid...

Embodiment 2

[0039] A pyrite acid plant with an annual output of 400,000 tons has a flue gas volume of 115,000m from the boiler and multi-tube dust collector 3 / h, containing iron oxide, silicon oxide, calcium oxide, aluminum oxide, magnesium oxide and other dust 15g / m 3 ~20g / m 3 , the flue gas inlet temperature is 300-360°C, the flue gas SO 2 The content is 11%, and the flue gas contains a small amount of HF, HCl, SO 3 It needs to be purified and absorbed. The annular overflow weir 2 is equipped with a water curtain to protect the inner wall of the smoke pipe. The high-temperature flue gas enters the turbulent washing section 3 through the annular overflow weir 2, where it is sprayed with the washing and absorbing liquid sent by the circulating pump 12 through the large-opening turbulent nozzle 4. The flue gas and the washing and absorbing liquid form a suspended dynamic foam area, where the gas-liquid two-phase contact is intense to complete the adsorption absorption and adiabatic eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com