A Jet Flow Plate Used in a Noodle Cooking Stove

A technology of jet flow plate and noodle cooking stove, which is applied in the field of food processing equipment, can solve the problems of poor tumbling effect, achieve good stirring, strengthen jet strength, and prevent insufficient impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

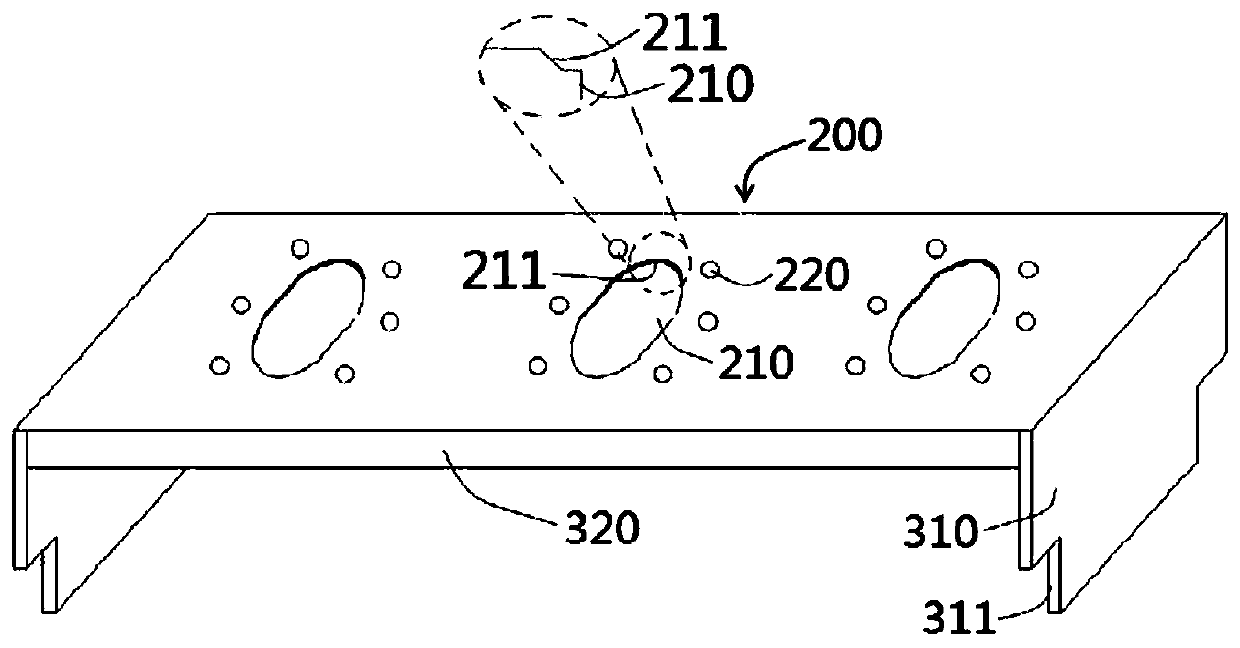

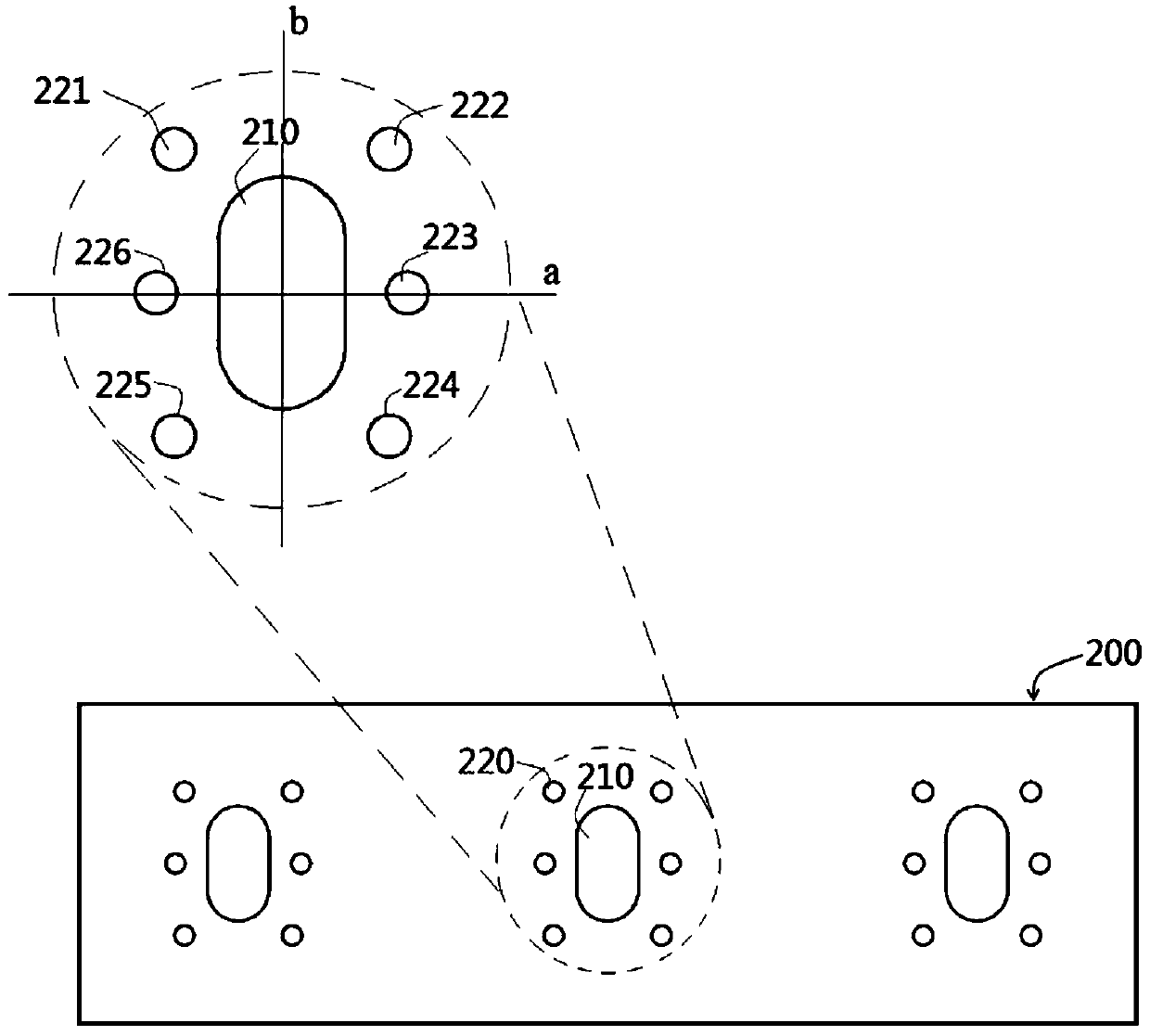

[0037] Refer to attached figure 1 , figure 2 and image 3 As shown, a jet plate used for a noodle cooking stove in this embodiment, the jet plate main body 200 includes a main water spray hole 210 and an auxiliary water spray hole 220, and the auxiliary water spray holes 220 are distributed in the main water spray hole 210 , the auxiliary water spray holes 220 are distributed symmetrically with respect to the center of the main water spray hole 210 . The main water spray hole 210 can spray the boiling hot water below the jet plate main body 200 to the top of the jet plate main body 200, and the auxiliary water spray hole 220 is used to impact and roll the dough around the top, so that the dough rolls better. Heating is more even.

[0038] The upper end of the main water spray hole 210 of this embodiment is provided with a drainage surface 211, the drainage surface 211 protrudes from the upper surface of the jet plate main body 200, and the drainage surface 211 is inclined ...

Embodiment 2

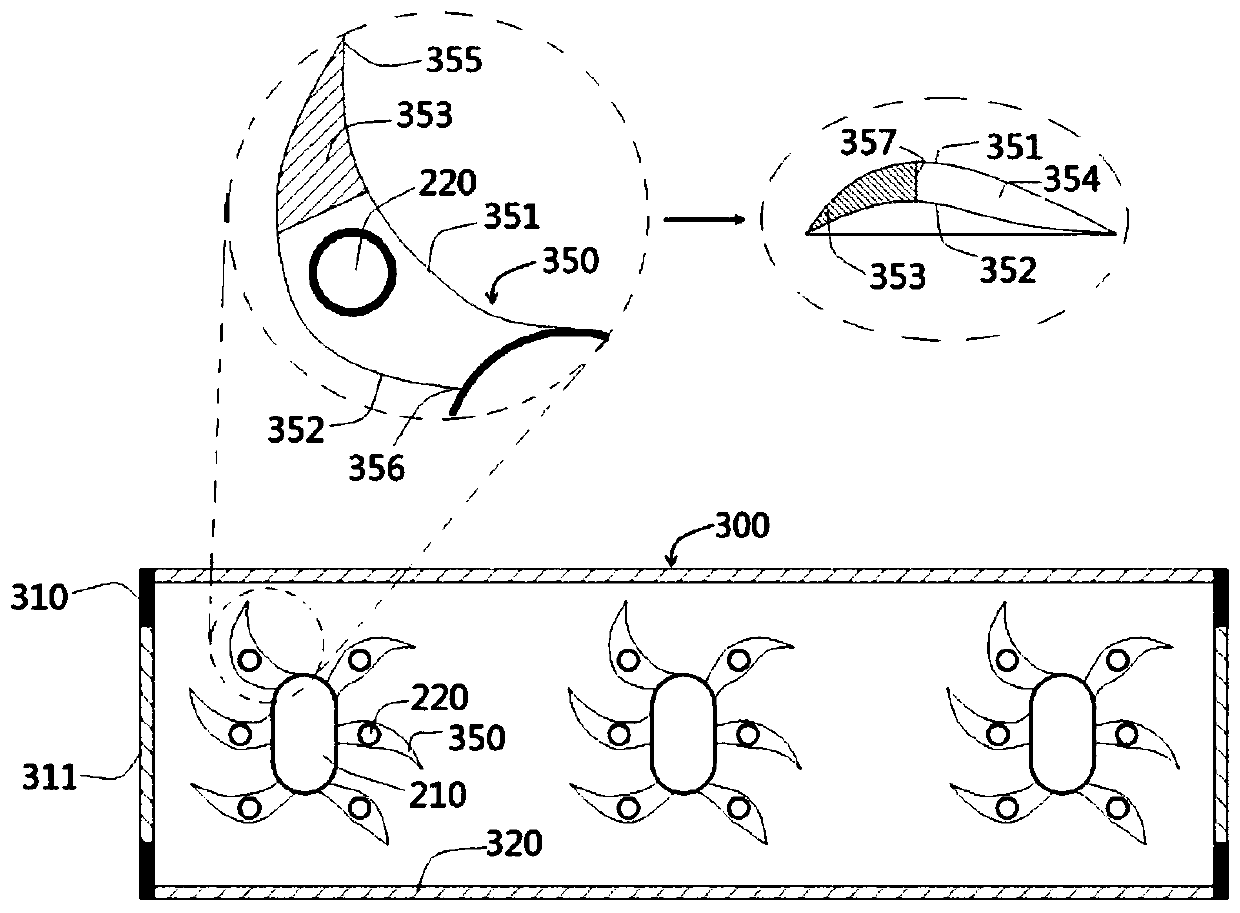

[0045] Refer to attached figure 1 , figure 2 and Figure 4 As shown, the basic structure of a jet plate used for a noodle cooking stove in this embodiment is the same as that of embodiment 1, except that the lower end surface 300 of the jet plate in this embodiment is provided with a diversion groove 360. The diversion groove 360 is disposed between the auxiliary water spray holes 220, and the diversion groove 360 is used to guide the water flow into the main water spray hole 210, so that the water flow ejected from the main water spray hole 210 is more powerful and sufficient.

[0046] The diversion groove 360 of this embodiment is recessed and arranged on the lower end surface 300 of the spray plate, the bottom slope 361 and the side slope 362 of the flow diversion groove 360 are inclined slopes, and one end of the side slope 362 is connected to the bottom slope 361, The other end is connected to the main water spray hole 210, and the depth of the side slope 362 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com