Prefabricated board room

A prefabricated assembly and prefabricated house technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as threats to ecological environment safety in disaster areas, and achieve the effect of reducing assembly time and facilitating disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

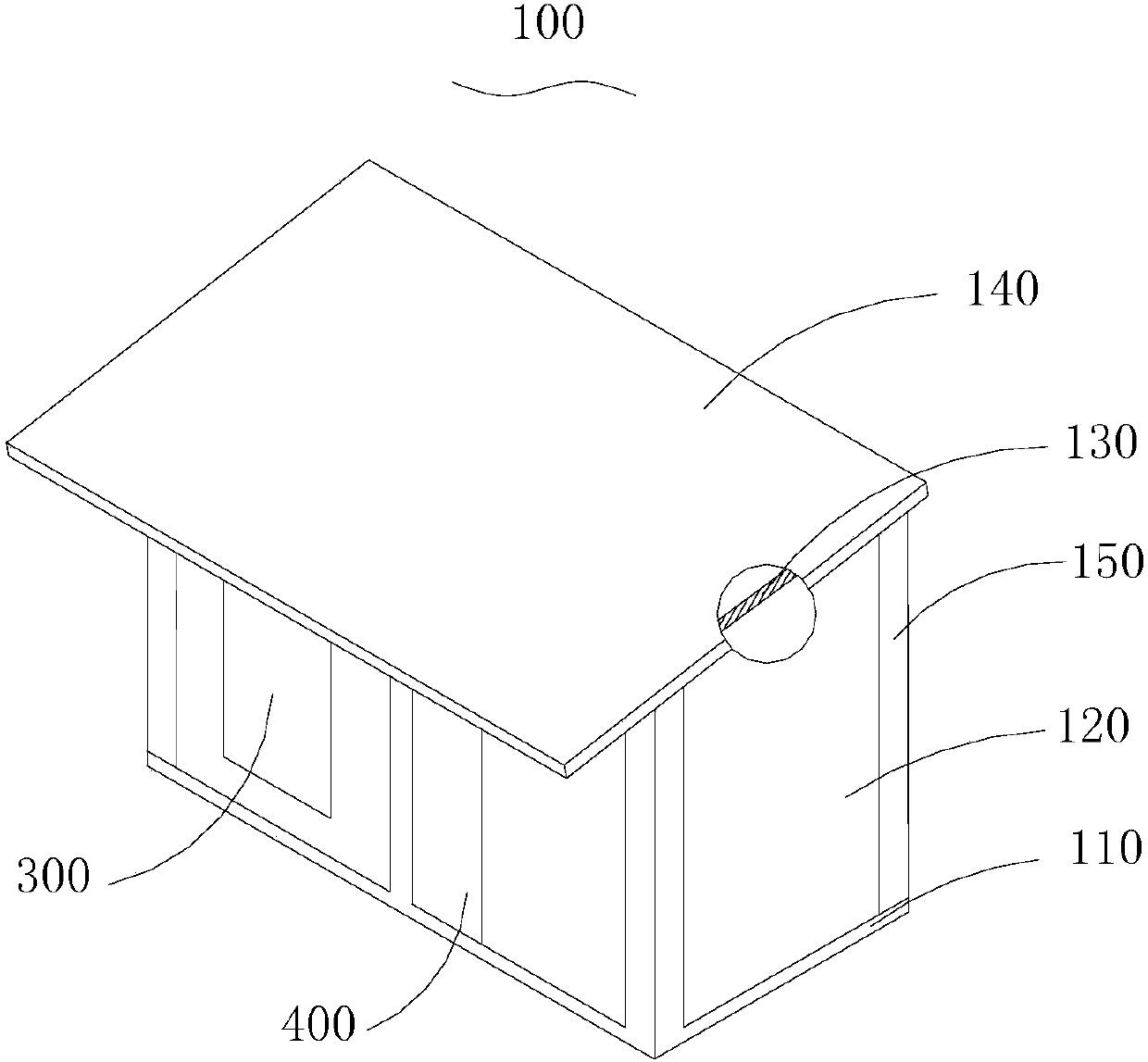

[0057] Such as figure 1 As shown, this embodiment provides a prefabricated prefabricated board house, which is a one-story board house 100 , including a steel frame body, spiral foundation piles 160 , a first wall board 120 and a first roof board 140 .

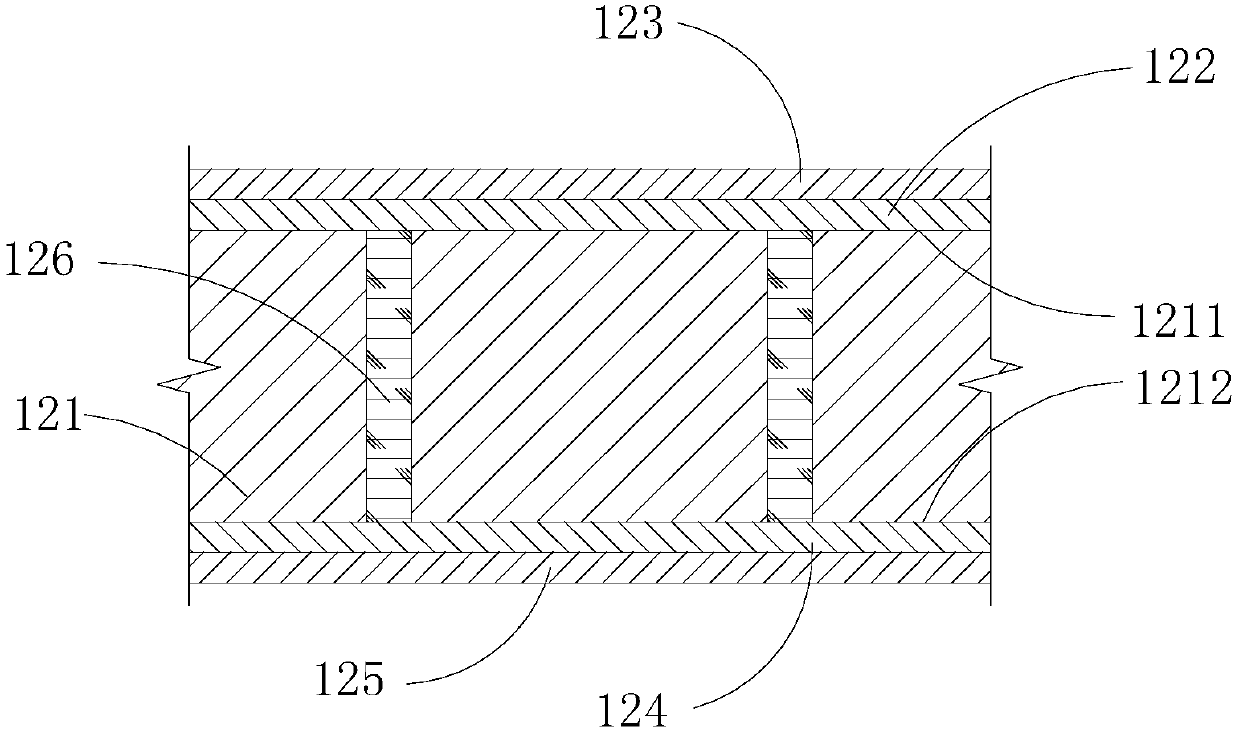

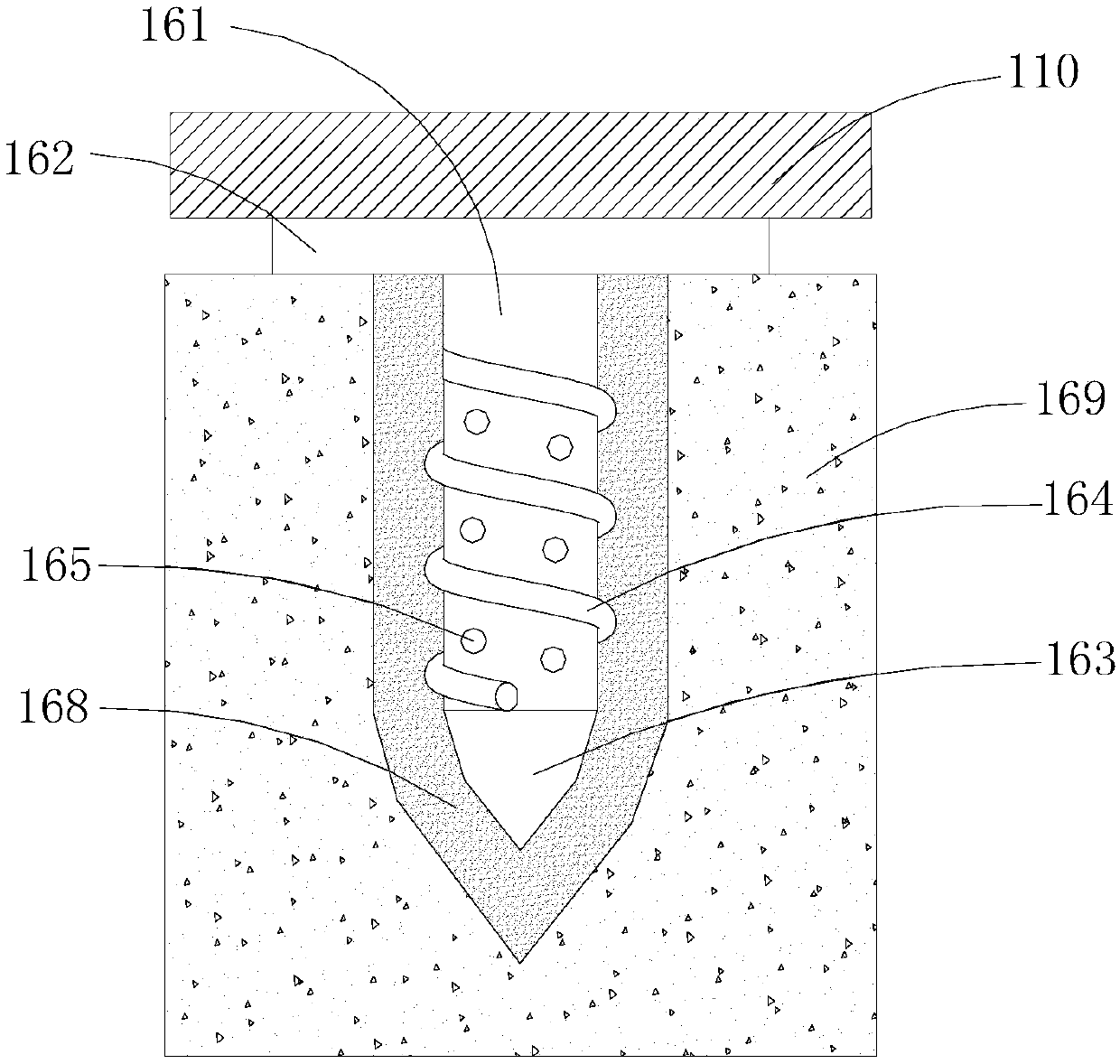

[0058] As an implementation of this embodiment, the steel frame body includes a first frame 110 , a second frame 130 and four first columns 150 . The first frame 110 and the second frame 130 are arranged oppositely, and each first column 150 connects the first frame 110 and the second frame 130, and each first column 150 is vertically arranged with the first frame 110, and each first column 150 It is perpendicular to the second frame 130 , that is, the first frame 110 and the second frame 130 are parallel. The first frame 110 is a fixed base plate, and the first frame 110 is fixed on the ground through the screw foundation pile 160 . The shapes of the first frame 110 and the second frame 130 can be rectangular, elliptical, c...

no. 2 example

[0074] Such as Figure 5 , 6 As shown, this embodiment provides a prefabricated prefabricated board house, which is a two-story board house 200, and the first-floor board house in this embodiment has the same structure as the one-story board house 100 in the first embodiment. Wherein only need to change the size of the first top board 140, make it meet the requirement of the bottom board of the second layer of two-layer design. The second floor is provided with a structure similar to the one-story board house 100 in the first embodiment on the top of the first embodiment.

[0075] The two-story board house 200 includes a third frame 210 , four second columns 240 , a second wall panel 220 and a second roof panel 230 . The second frame 130 is provided with the third frame 210 at intervals, the second column 240 is arranged between the second frame 130 and the third frame 210 and connected with the top of the first column 150, the second top plate 230 is arranged on the third f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com