High-light-shading high-barrier liquid package film and production method thereof

A high-barrier, packaging film technology, applied in packaging, household packaging, packaged food, etc., can solve problems such as insufficient peel fastness, reduced barrier properties, broken packages, etc., to improve ink transfer effect, good water vapor barrier properties, The effect of convenient waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

[0047] The production method of the described high light-shielding and high-barrier liquid packaging film comprises the following steps:

[0048] Step 1, producing opalescent matte PE co-extruded film layer, producing EVOH co-extruded film layer and aluminizing the EVOH co-extruded film layer:

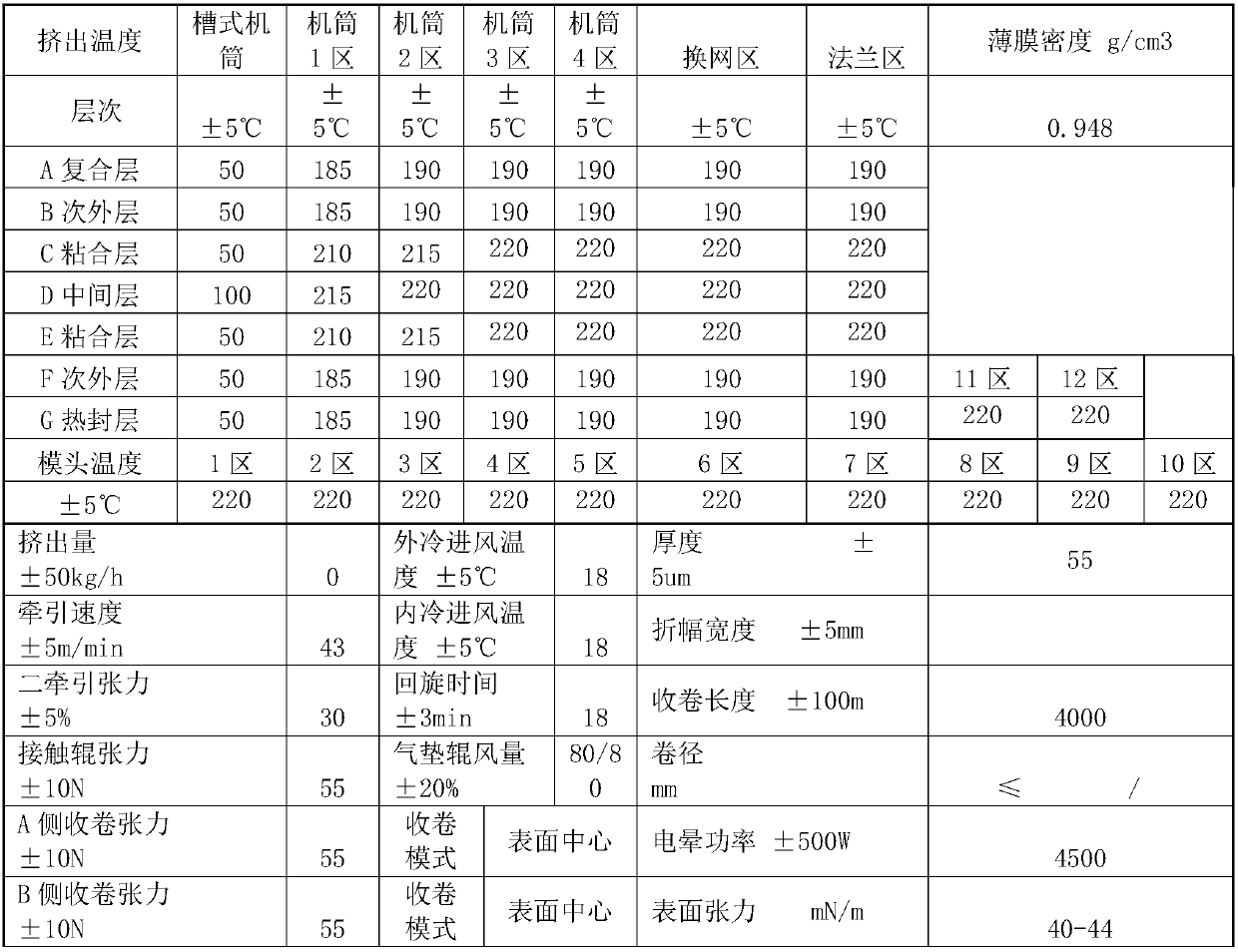

[0049] Production of milky white matte PE co-extrusion film layer: Add the materials contained in the printing layer, middle layer and extrusion layer to the co-extrusion blown film machine respectively to obtain the milky white matte by three-layer co-extrusion PE co-extruded film layer; the processing parameters of the milky white matting PE co-extruded film layer are shown in Table 1 below:

[0050] Table 1

[0051]

[0052] Production of EVOH co-extruded film layer: Add the materials contained in the A composite layer, B sub-outer layer, C adhesive layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com