Efficient rubber crusher for waste and old tyres

A waste tire and rubber breaker technology, applied in recycling technology, mechanical material recovery, grain processing, etc., can solve the problems of short continuous working time, low roller speed, roller damage, etc., to reduce transmission energy consumption, The effect of increasing rotation speed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

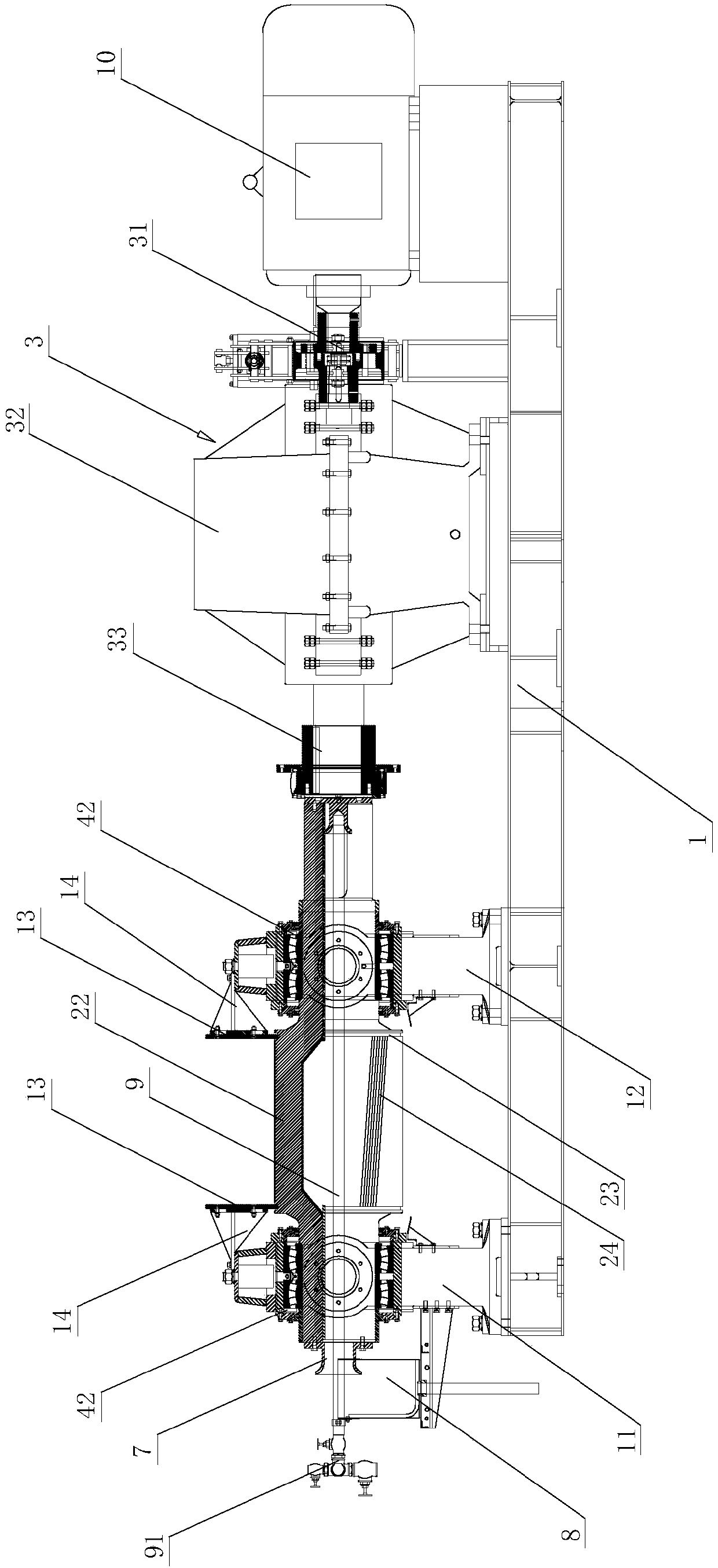

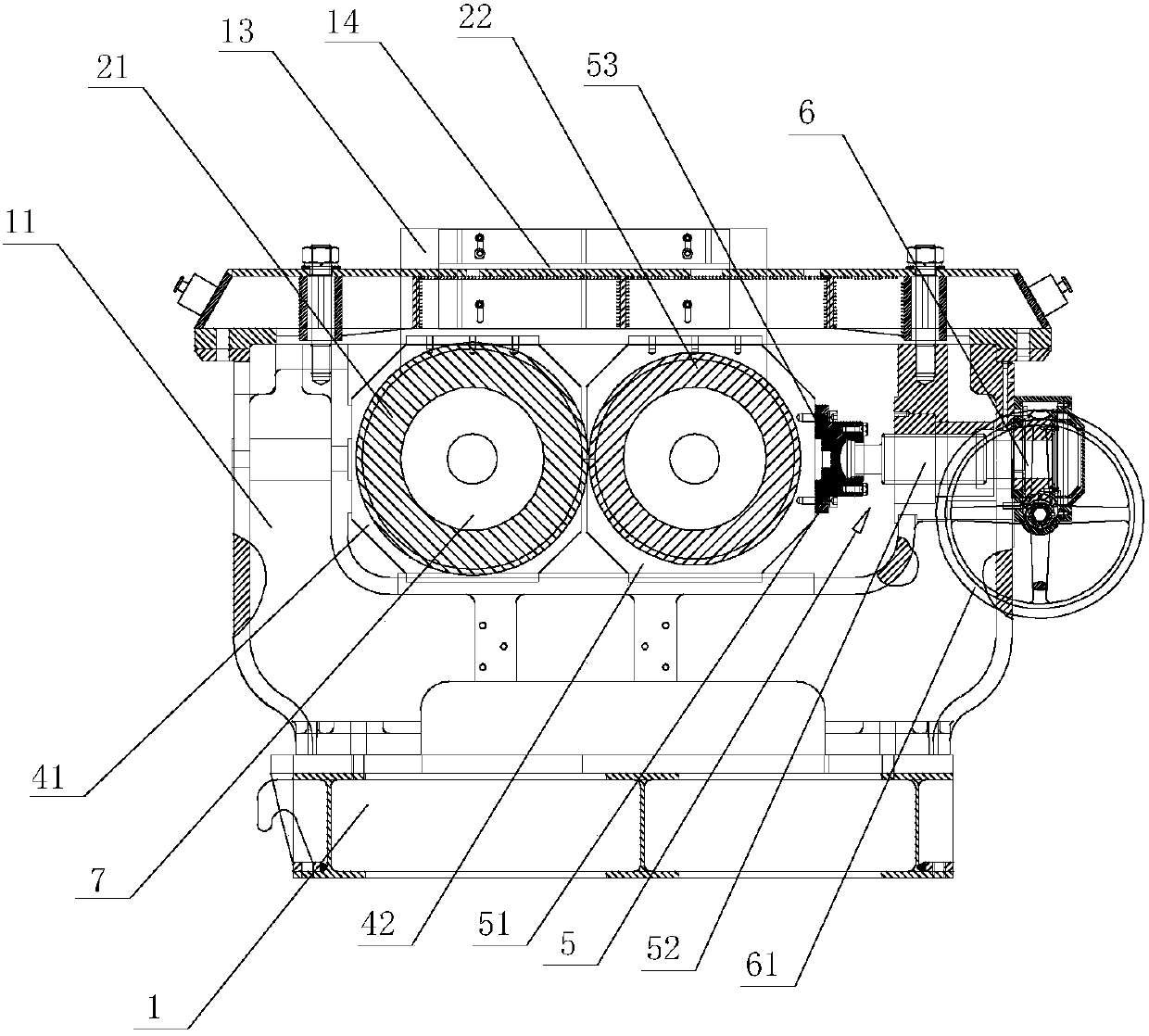

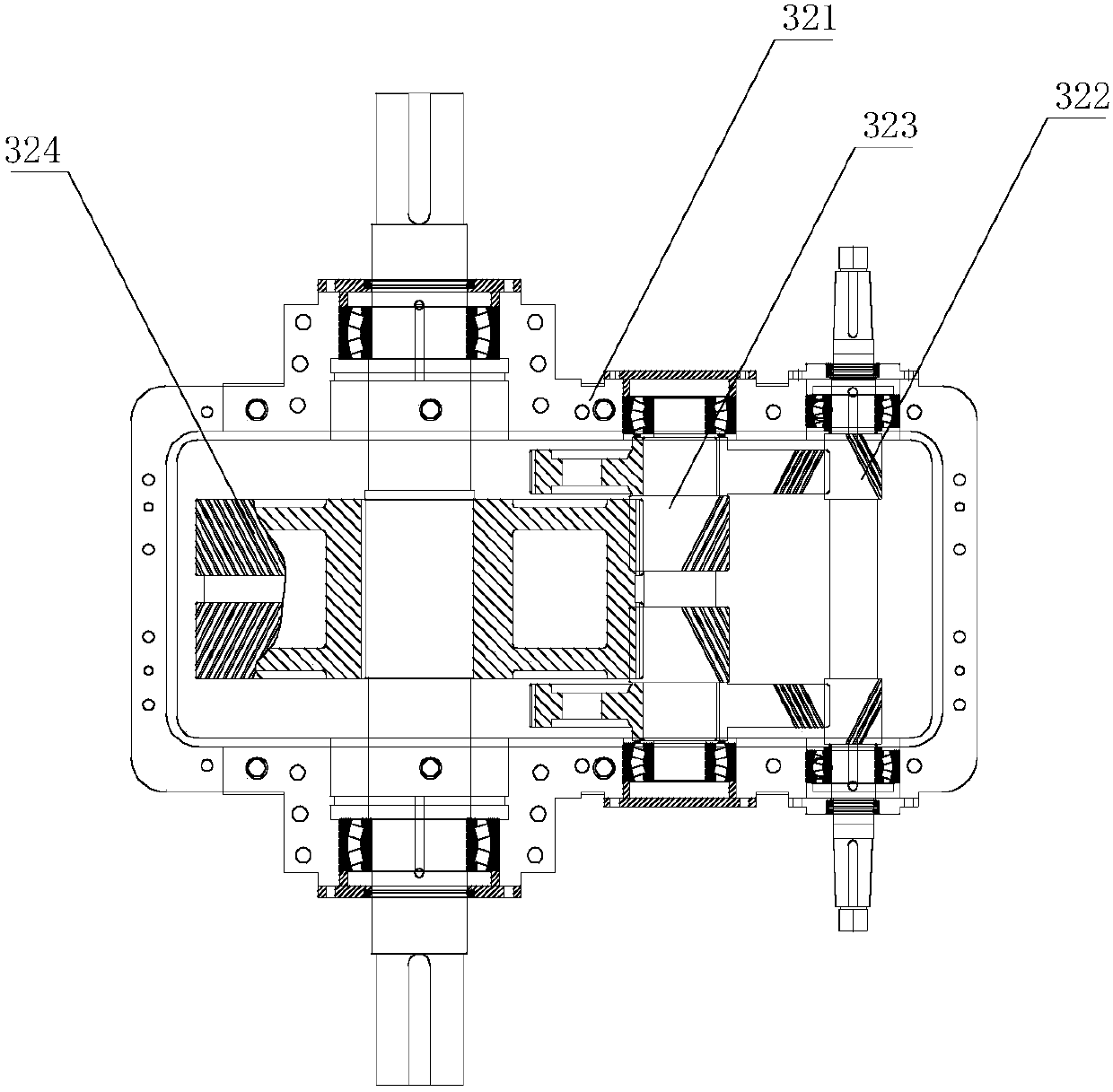

[0017] combine Figure 1 to Figure 3 , a high-efficiency rubber breaking machine for waste tires, including a base 1, a left frame 11, a right frame 12, a rear roller 21, a front roller 22 and a transmission mechanism 3, the left frame 11 and the right frame The frame 12 is relatively vertically arranged above the base 1 , and the bottoms of the left frame 11 and the right frame 12 are fixedly connected with the base 1 . The rear roller 21 and the front roller 22 are horizontally and parallelly arranged between the left frame 11 and the right frame 12, the rear roller 21 is a driving roller, the front roller 22 is a driven roller, and the rear roller There is a gap between 21 and the front roller 22, the rear roller 21 ends are respectively provided with the rear bearing seat 41, the front roller 22 ends are respectively provided with the front bearing seat 42, the rear rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com