All-fiber shaping method for deep-hole shell copper component

A full fiber and shell technology, applied in the field of full fiber forming of deep hole shell copper parts, can solve the problems of insufficient strength and toughness, and achieve the effects of good dimensional consistency, high surface finish, and improved material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

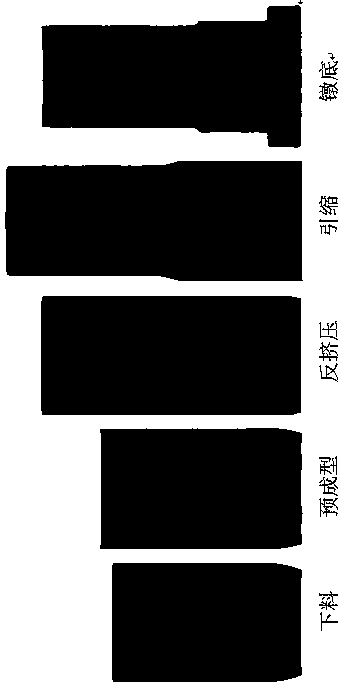

Embodiment 1

[0027] (1) Cutting: The outer diameter of the upper end of the copper part of the deep hole shell is φ15.5mm, the outer diameter of the middle part is φ16.9mm, the outer diameter of the lower end is φ21.4mm, the inner diameter of the deep hole is φ9.1mm, and the height is 42.5mm. The raw material brass rod is φ16.7mm, calculate the required raw material length, and cut off the blank with a length of 34mm.

[0028] (2) Homogenization heat treatment: put the billet obtained in step (1) into a protective nitrogen (nitrogen purity 99.9%, humidity less than 0.05%) atmosphere for heat treatment, and heat up to a temperature of 560±5°C with the furnace, and the holding time is 2.5h , followed by furnace cooling under a protective atmosphere.

[0029] (3) Preforming: Put the homogenized billet obtained in step (2) into the cavity of the upsetting billet mold, and evenly apply a layer of lubricant on the surface of the billet and the inner surface of the mold cavity to upset the billet...

Embodiment 2

[0036] Embodiment 2 (other steps and parameters are the same as embodiment 1)

[0037] (1) Cutting: the raw material copper rod is φ16mm, calculate the length of the required raw material, and cut off the blank with a length of 36mm.

[0038] (2) Homogenization heat treatment: put the billet obtained in step (1) into a protective nitrogen (nitrogen purity 99.9%, humidity less than 0.05%) atmosphere for heat treatment, heat up to a temperature of 400±5°C with the furnace, and hold for 2 hours. Subsequent furnace cooling is carried out under a protective atmosphere.

[0039] (3) Preforming: Put the homogenized billet obtained in step (2) into the cavity of the upsetting billet mold, and evenly apply a layer of lubricant on the surface of the billet and the inner surface of the mold cavity to upset the billet Cold plastic deformation is prepared to obtain a preform.

[0040] (4) Back-extrusion: Put the deep-hole shell copper preform obtained in step (3) into the back-extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com