Method for using parachloronitrobenzene to prepare parachloroaniline through selective hydrogenation

A technology of p-chloronitrobenzene and p-chloroaniline, which is applied in the field of selective hydrogenation of p-chloronitrobenzene to prepare p-chloroaniline, which can solve the problems affecting the overall performance of the catalyst, easy aggregation of platinum nanoparticles, and harsh preparation conditions. Achieve the effects of good selective catalytic hydrogenation effect, superior catalytic activity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

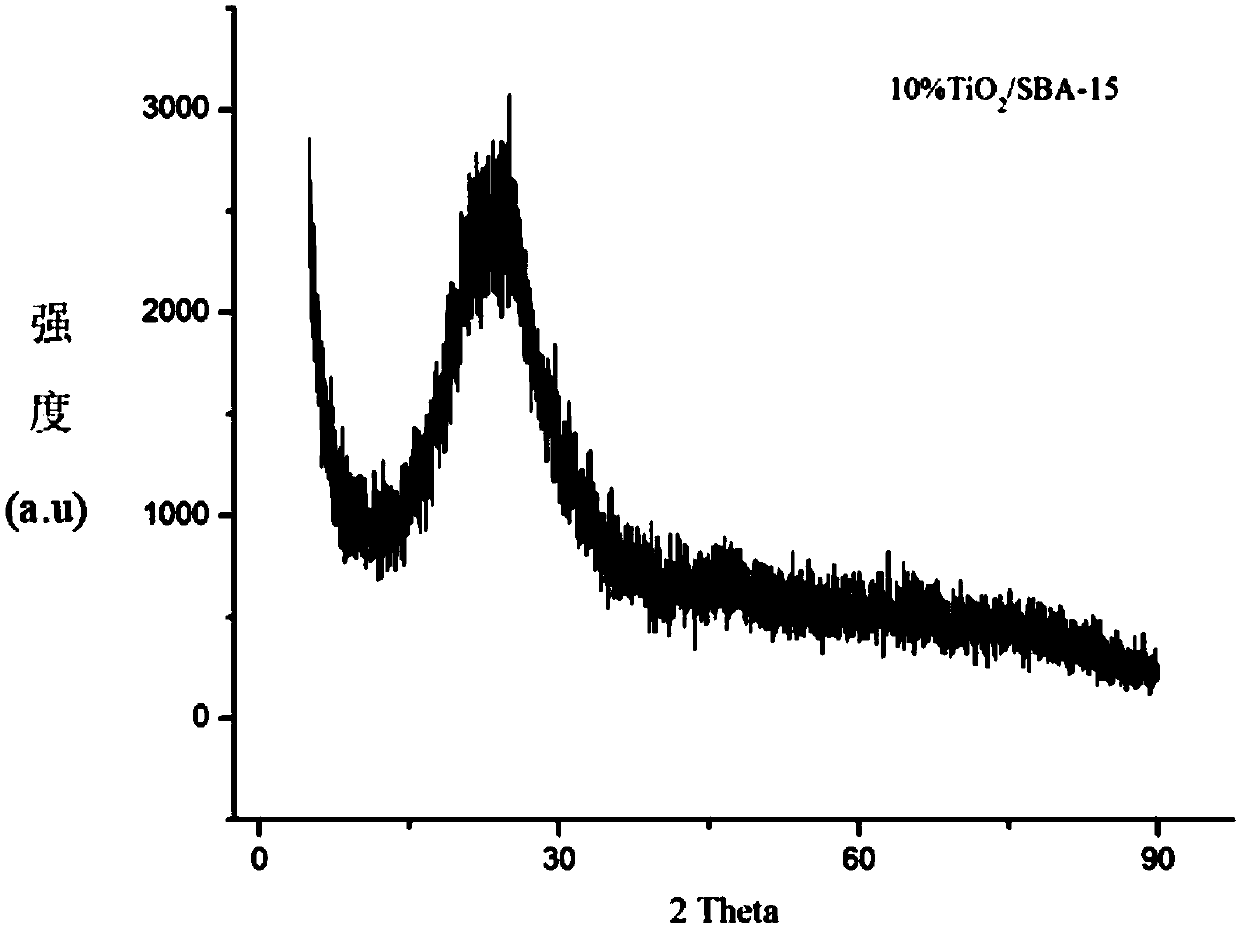

[0039] The mesoporous silicon material SBA-15 was added to 15 mL of absolute ethanol, and ultrasonically oscillated for 2 hours to obtain a mixture of treated SBA-15 and absolute ethanol. Under the condition of stirring, drop 0.5mL butyl titanate into the above mixture drop by drop, stir for 1h; slowly add 1mL water to the mixture to hydrolyze the butyl titanate, and continue stirring for 1h to completely hydrolyze the butyl titanate . Heat and stir at 40°C to make the above mixture into a gel. Vacuum drying overnight at 80°C to get 10% TiO 2 / SBA-15 composite carrier (TiO in the composite carrier 2 Content is 10wt%). Take 0.702gTiO 2 / SBA-15 composite carrier dispersed in 100mL deionized water, add 10mL anhydrous methanol, ultrasonically disperse for 10min, then add 0.1mL chloroplatinic acid solution, ultrasonically disperse for 20min, and then place the solution under ultraviolet light under stirring conditions After 12 hours, the resulting solution was filtered and was...

Embodiment 2

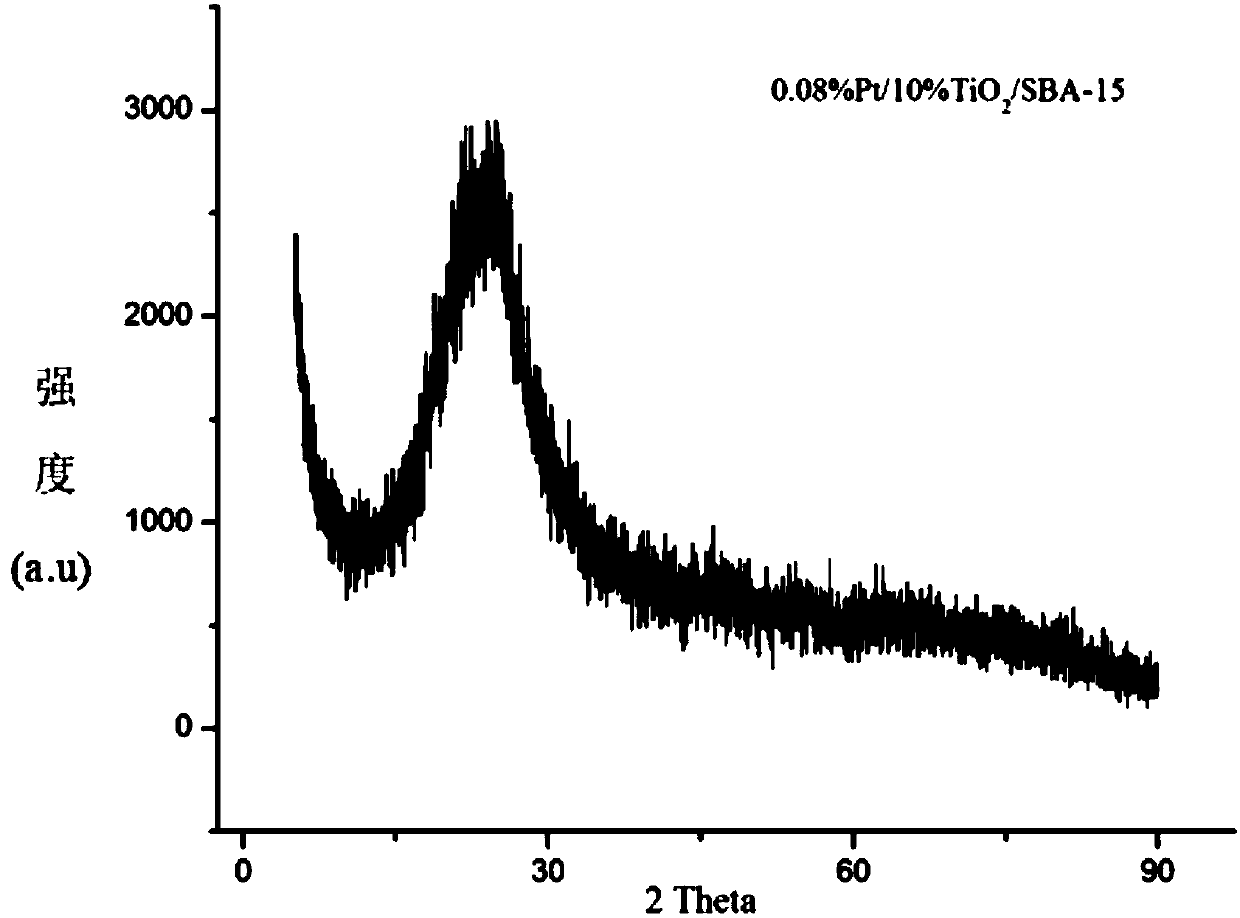

[0041] With embodiment 1, the difference is that Pt / TiO 2 The mass fraction of Pt in / SBA-15 is 0.08%, that is, 0.08%Pt / 10%TiO 2 / SBA-15.

Embodiment 3

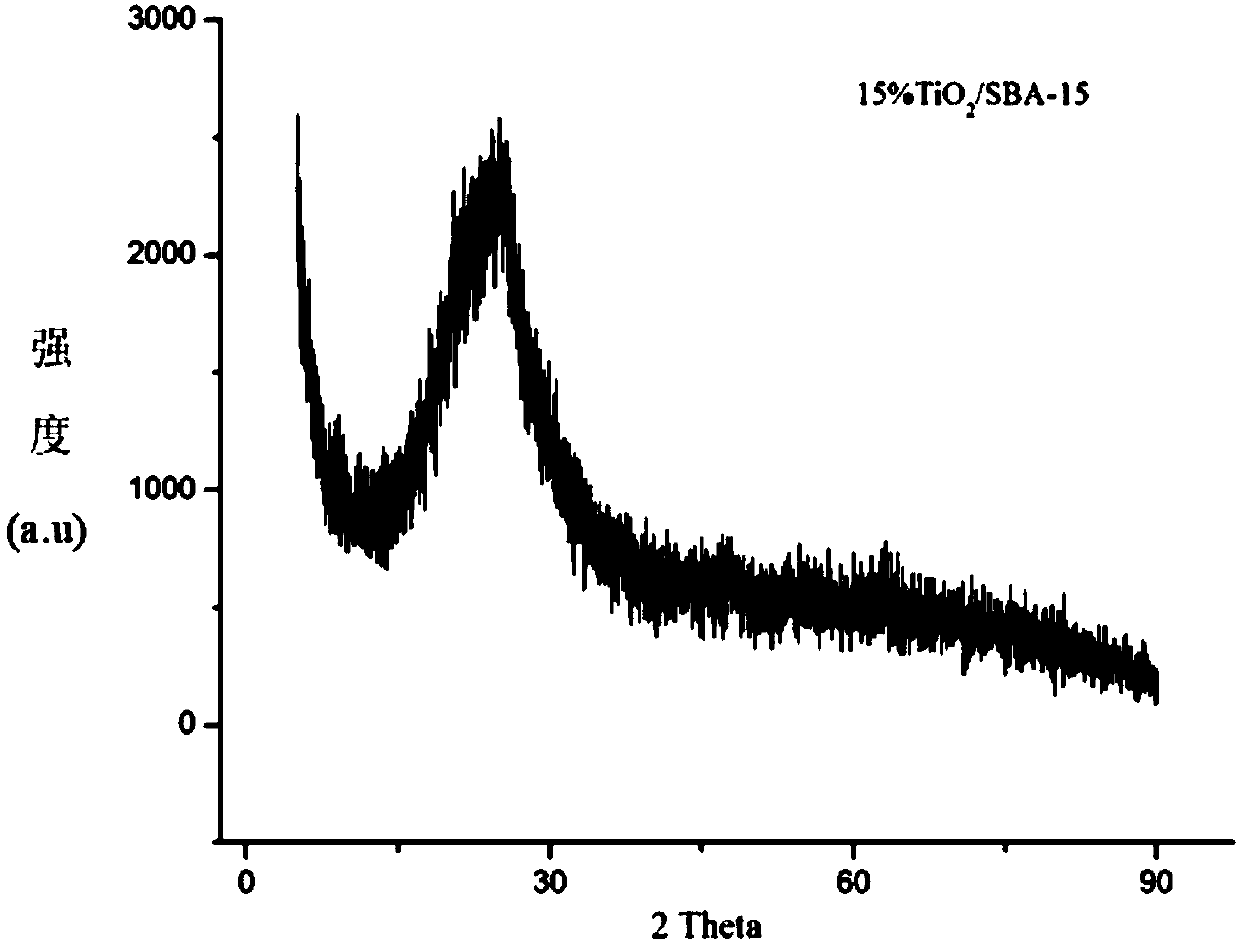

[0043] With embodiment 1, the difference is that Pt / TiO 2 / TiO in SBA-15 2 The mass fraction in the composite support is 15%, that is, 0.1%Pt / 15%TiO 2 / SBA-15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com