Surface active agent, preparation method thereof and application of surface active agent

A technology of surfactants and raw materials, applied in the field of surfactants and their preparation, can solve the problems of unstable aerosol properties, complicated manufacturing process, and short service life, and achieve easy implementation, simple preparation process, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

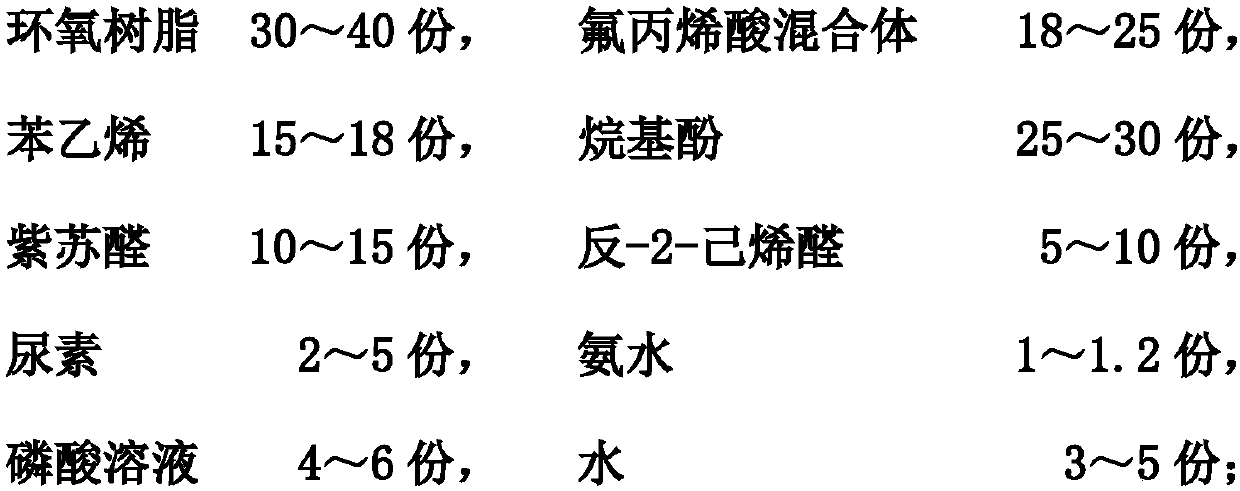

Method used

Image

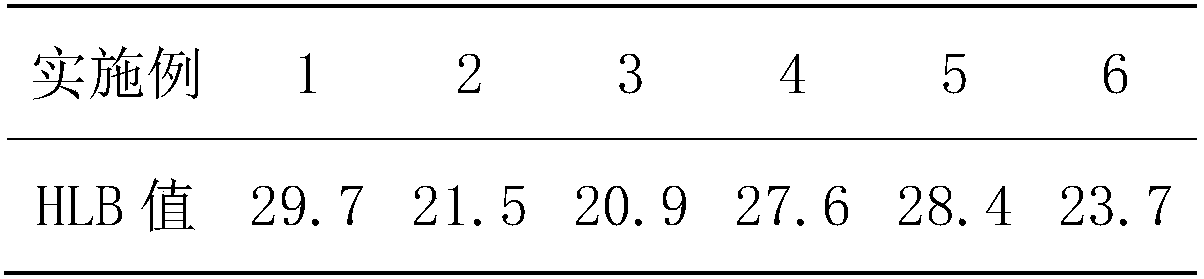

Examples

Embodiment 1

[0023] 1) Preparation of fluoroacrylic acid mixture

[0024] 4 parts of methacrylic acid, 2.5 parts of butyl acrylate and 3.5 parts of hexafluorobutyl methacrylate were mixed, and stirred for 25 minutes to prepare a fluoroacrylic acid mixture.

[0025] 2) Preparation of surfactant

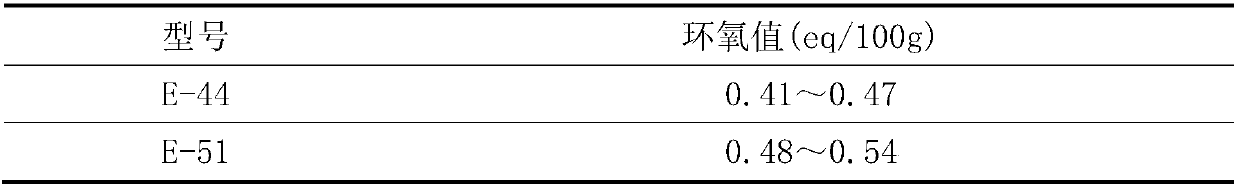

[0026] 35 parts E-44 epoxy resin, 20 parts fluoroacrylic acid mixture, 16 parts styrene, 28 parts alkyl phenol, 12 parts perillaldehyde, 8 parts trans-2-hexenal, 3 parts urea, 1.1 parts Ammonia water, 5 parts of phosphoric acid solution and 4 parts of water are mixed, stirred evenly, and then chemically refluxed at a temperature of 100-105 DEG C of an oil bath to prepare a surfactant.

[0027] 3) Preparation of aerosols

[0028] 15.95 parts of plant essential oil, 1.5 parts of octyl methoxycinnamate, 2.5 parts of ethanol, and 0.05 part of surfactant are mixed and stirred evenly, then 80 parts of purified water are added under stirring conditions, and the emulsion is obtained after mixing uniforml...

Embodiment 2

[0032] The difference from Example 1 is:

[0033] The fluoroacrylic acid mixture is prepared by mixing the following raw material components, in parts by weight: 3 parts of methacrylic acid, 2 parts of butyl acrylate, and 3 parts of hexafluorobutyl methacrylate.

[0034] The surfactant is prepared from the following raw material components in parts by weight, at 100 ° C oil bath temperature, through chemical reflux: 30 parts of E-44 epoxy resin, 18 parts of fluoroacrylic acid mixture, 15 parts of styrene, alkane 25 parts of base phenol, 10 parts of perillaldehyde, 5 parts of trans-2-hexenal, 2 parts of urea, 1 part of ammonia water, 4 parts of phosphoric acid solution, and 3 parts of water.

Embodiment 3

[0036] The difference from Example 1 is:

[0037] The fluoroacrylic acid mixture is prepared by mixing the following raw material components, in parts by weight: 5 parts of methacrylic acid, 3 parts of butyl acrylate, and 4 parts of hexafluorobutyl methacrylate.

[0038] The surfactant is prepared by chemical reflux from the following raw material components in parts by weight: 40 parts of E-44 epoxy resin, 25 parts of fluoroacrylic acid mixture, 18 parts of styrene, 30 parts of alkyl phenol, and 15 parts of perillaldehyde parts, 10 parts of trans-2-hexenal, 5 parts of urea, 1.2 parts of ammonia water, 6 parts of phosphoric acid solution, and 5 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com