Low-NOx combustor super low in nitrogen oxide emission

A technology of nitrogen oxides and burners, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of large excess air coefficient, high flame height, and low thermal efficiency, so as to reduce the excess air coefficient and improve Effects of thermal efficiency and flame diameter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

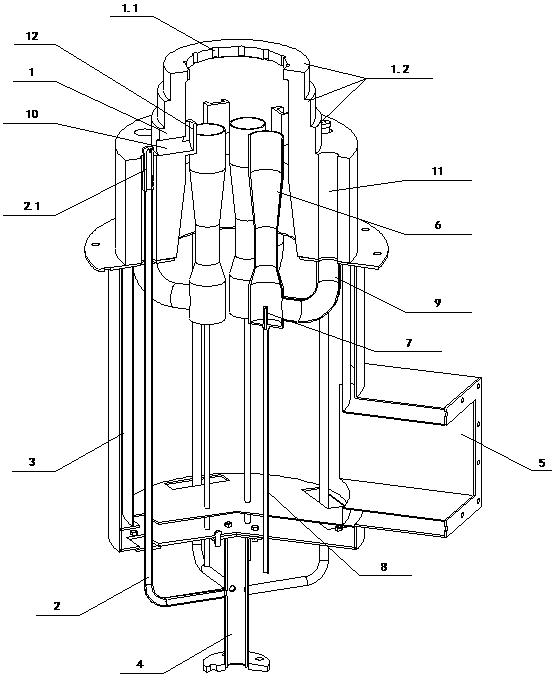

[0045] see figure 1 , the invention relates to an ultra-low nitrogen oxide emission low NO x The burner includes a refractory brick 1, a flame-stabilizing plate 1.1, a flame-stabilizing step 1.2, an air gun 2, an air gun nozzle 2.1, a shell 3, a gas collecting pipe 4, an air inlet 5, a Venturi nozzle 6, an ejector nozzle 7, Injection gas pipe 8 , flue gas return pipe 9 , first flue gas return hole 10 , second flue gas return hole 11 and guide port 12 .

[0046] The air distribution system includes refractory bricks 1, shell 3 and air inlet 5, the fuel gas system includes gas collecting pipe 4 and air gun 2, and the flue gas recirculation system includes ejection air pipe 8, ejection gas nozzle 7, flue gas return pipe 9, Venturi nozzle6.

[0047]The upper part of the refractory brick 1 is a hollow flame-stabilizing step 1.2 with a stepped surface, and the lower part is a hollow cylinder. Several semicircular flame-stabilizing plates 1.1 are opened on the inner wall of the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com