Method for control and in-situ detection of enzymatic activity under irradiation of electronic beams

A technology of electron beam irradiation and in-situ detection, which is used in the determination/inspection of microorganisms, biochemical equipment and methods, material resistance, etc. Monitoring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

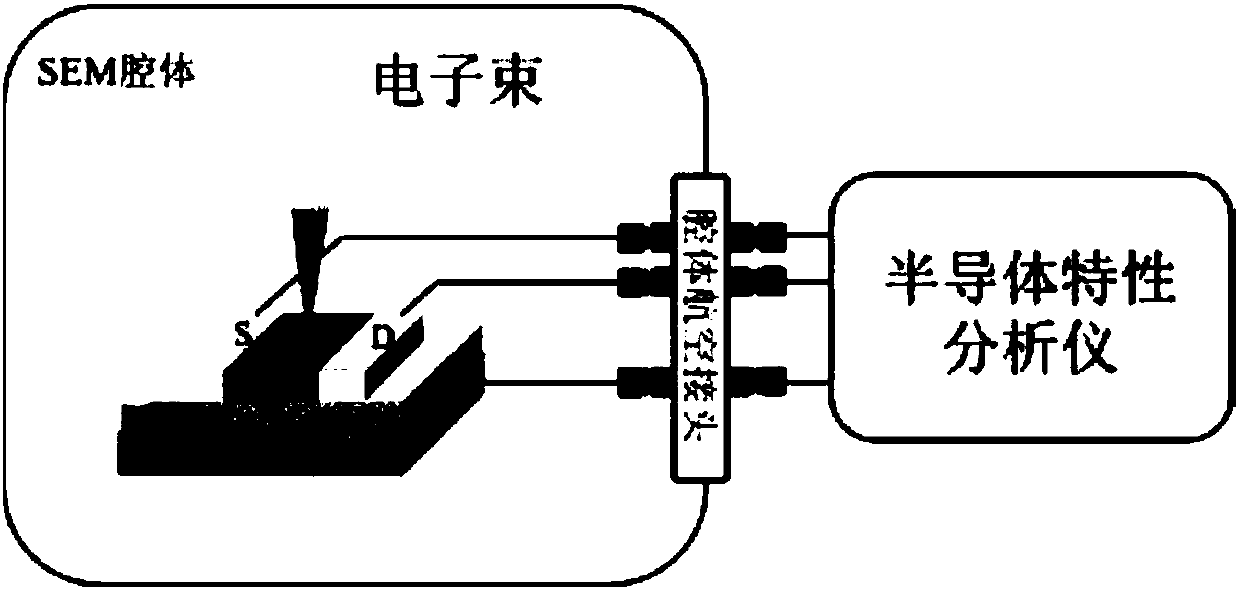

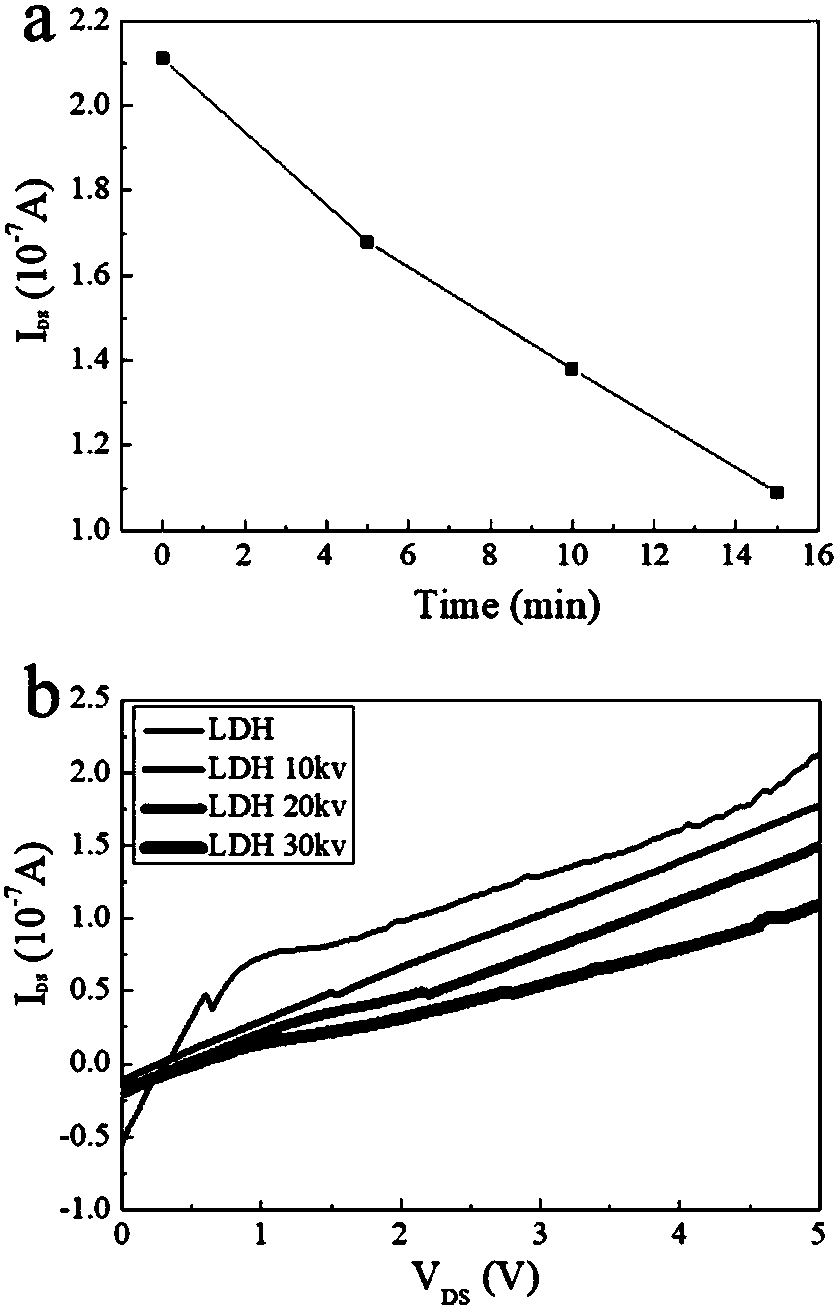

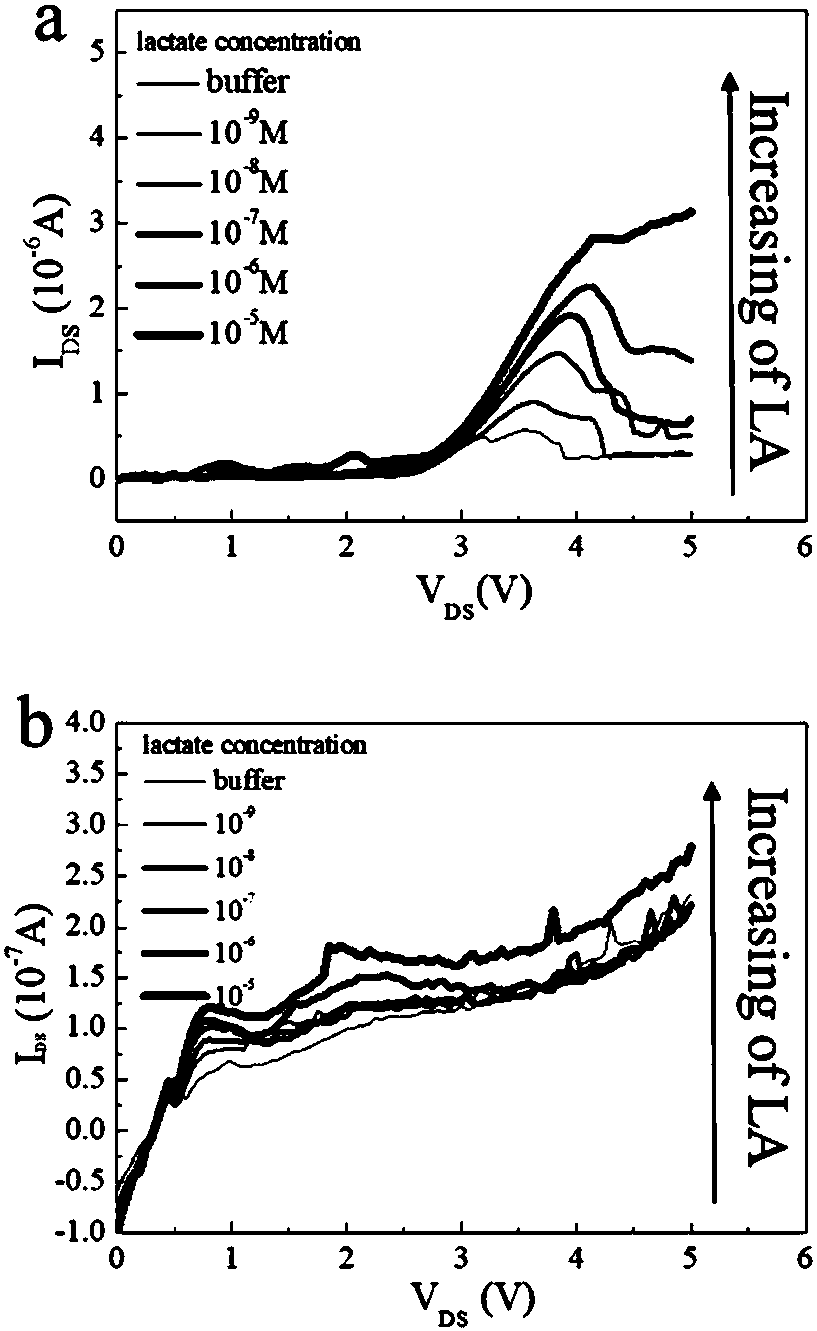

[0023] Example 1: Taking lactate dehydrogenase as the research object. First prepare TiO 2 Thin film field effect tube, place the strip array mask on the surface of the field effect tube, use electron beam evaporation to plate gold electrodes, and use a lead wire connector to weld multiple leads to the gold electrodes respectively, then use inorganic glue to protect the electrodes, curing time For more than 6h. Secondly, 2µL of 0.5wt% chitosan was added dropwise between multiple source-drain electrodes to spread evenly; after 1h, 2µL of 2.5% glutaraldehyde was added dropwise to spread evenly; after 1h, continue to drop 2µL Lactate dehydrogenase; after fixing for 1h, wash with ultrapure water at last. Put the device into the SEM sample stage, use silicon as the gate electrode, any two adjacent electrodes in the gold electrode array as the source and drain electrodes, connect the other floating end of the lead to the BNC connector and connect it to the aviation connector on th...

Embodiment 2

[0024] Embodiment 2: Taking urease as the research object. First prepare TiO 2 Thin film field effect tube, place the strip array mask on the surface of the field effect tube, use electron beam evaporation to plate gold electrodes, and use a lead wire connector to weld multiple leads to the gold electrodes respectively, then use inorganic glue to protect the electrodes, curing time For more than 6h. Secondly, 2µL of 0.5wt% chitosan was added dropwise between multiple source-drain electrodes to spread evenly; after 1h, 2µL of 2.5% glutaraldehyde was added dropwise to spread evenly; after 1h, continue to drop 2µL Urease; after fixing for 1 h, wash with ultrapure water at last. Put the device into the SEM sample stage, use silicon as the gate electrode, any two adjacent electrodes in the gold electrode array as the source and drain electrodes, connect the other floating end of the lead to the BNC connector and connect it to the aviation connector on the cavity. Outside the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com