Application of immobilized laccase in methylene blue decoloration

A technology of methylene blue decolorization and immobilization of laccase, which is applied to the direction of redox enzymes fixed on or in inorganic carriers, fixed on/in organic carriers, etc., and can solve the technical difficulties of chromaticity removal of organic matter and other problems , to achieve high reuse rate, increase surface area, and high-efficiency treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 0.2 g of the carboxyl carbon nanotubes obtained from the above reaction and disperse them into 5 mL of 6% n-octane solution, add 0.2 g of sodium dodecyl sulfate and 30 mL of water, and dissolve in ice for 15 min with ultrasound;

[0031] (2) Add 4 mL of methyl methacrylate, 1 mL of divinylbenzene, and 8 mL of 1% potassium persulfate at a reaction temperature of 70 °C, stir and polymerize for 24 h. After the reaction is completed, cool down to room temperature naturally and centrifuge;

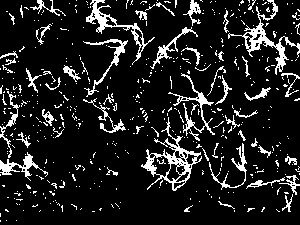

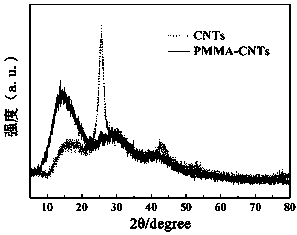

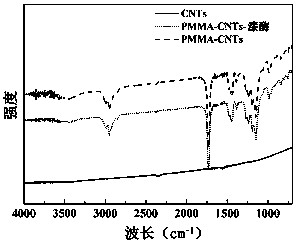

[0032] (3) The solid obtained from the above reaction is alternately washed with water and ethanol, dried in vacuum, cooled, and the product is collected to obtain black solid particles, which are carboxyl carbon nanotubes coated with polymethyl methacrylate;

[0033] (4) Weigh 0.2 g of carboxyl carbon nanotubes coated with polymethyl methacrylate, add 20 ml of 10% glutaraldehyde aqueous solution, stir mechanically at room temperature for 6 h, and wash with water after the react...

Embodiment approach 2

[0038] (1) Weigh 0.2 g of the carboxyl carbon nanotubes obtained from the above reaction and disperse them into 5 mL of 6% n-octane solution, add 0.2 g of sodium dodecyl sulfate and 30 mL of water, and dissolve in ice for 15 min with ultrasound;

[0039] (2) Add 4 mL of methyl methacrylate, 1 mL of divinylbenzene, and 8 mL of 1% potassium persulfate at a reaction temperature of 70 °C, stir and polymerize for 24 h. After the reaction is completed, cool down to room temperature naturally and centrifuge;

[0040] (3) The solid obtained from the above reaction is alternately washed with water and ethanol, dried in vacuum, cooled, and the product is collected to obtain black solid particles, which are carboxyl carbon nanotubes coated with polymethyl methacrylate;

[0041] (4) Weigh 0.2 g of carboxyl carbon nanotubes coated with polymethyl methacrylate, add 20 ml of 10% glutaraldehyde aqueous solution, stir mechanically at room temperature for 6 h, and wash with water after the react...

Embodiment approach 3

[0046] (1) Weigh 0.2 g of the carboxyl carbon nanotubes obtained from the above reaction and disperse them into 5 mL of 6% n-octane solution, add 0.2 g of sodium dodecyl sulfate and 30 mL of water, and dissolve in ice for 15 min with ultrasound;

[0047] (2) Add 4 mL of methyl methacrylate, 1 mL of divinylbenzene, and 8 mL of 1% potassium persulfate at a reaction temperature of 70 °C, stir and polymerize for 24 h. After the reaction is completed, cool down to room temperature naturally and centrifuge;

[0048] (3) The solid obtained from the above reaction is alternately washed with water and ethanol, dried in vacuum, cooled, and the product is collected to obtain black solid particles, which are carboxyl carbon nanotubes coated with polymethyl methacrylate;

[0049] (4) Weigh 0.2 g of carboxyl carbon nanotubes coated with polymethyl methacrylate, add 20 ml of 10% glutaraldehyde aqueous solution, stir mechanically at room temperature for 6 h, and wash with water after the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com