Dust removal system

A technology of dust removal system and dust removal cylinder, which is applied in the directions of gas dust removal, dispersed particle filtration, combined device, etc., can solve the problems of large turning radius, large running noise, and difficult layout of transportation vehicles, so as to optimize dust removal efficiency and dust removal effect and save energy. The effect of reducing maintenance and replacement costs and reducing the maintenance and replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

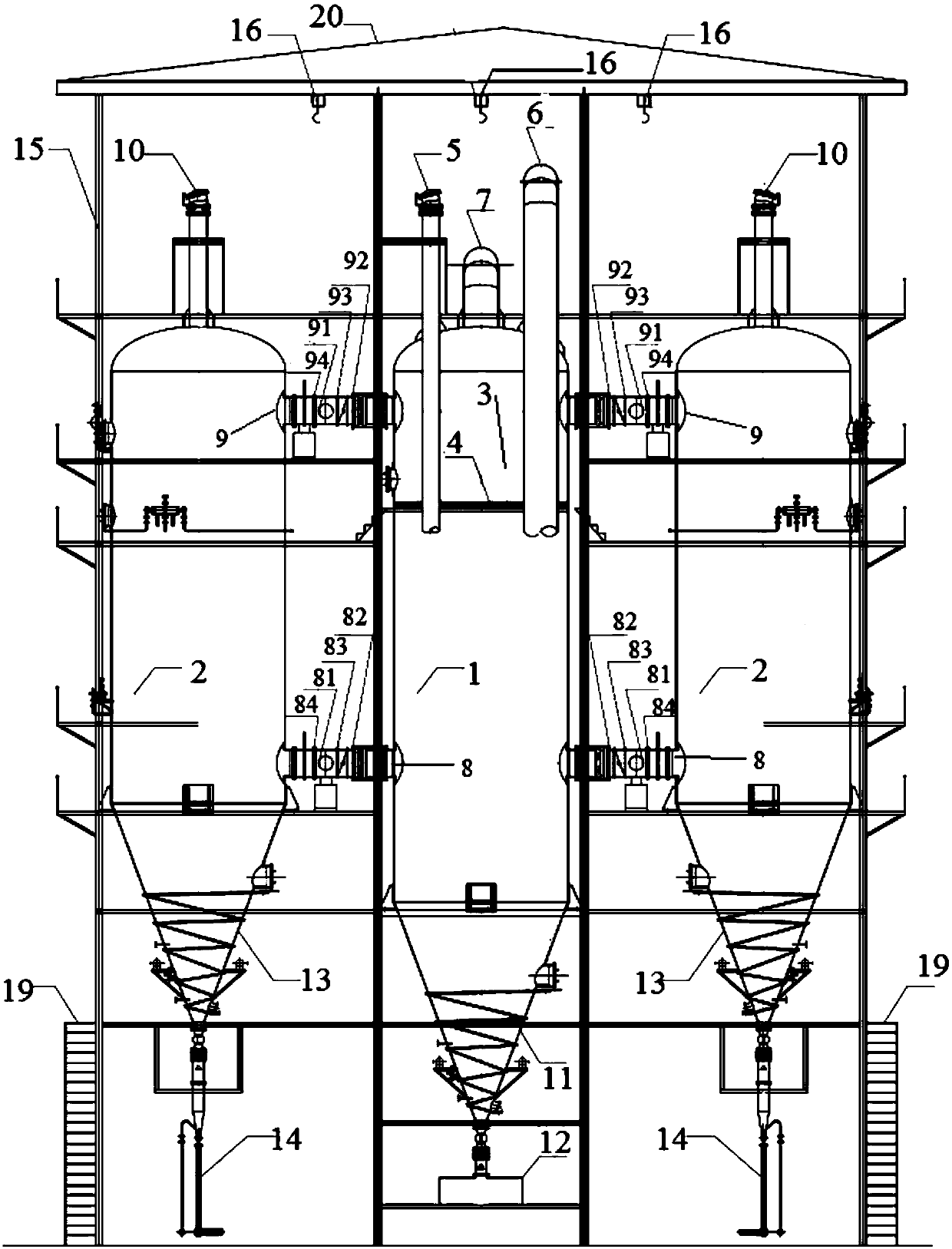

[0026] Embodiment 1: as figure 1 As shown, the dust removal system includes a cyclone dust collector 1 and a bag filter. The bag filter includes a plurality of dust removal cylinders 2. The number of dust removal cylinders can be determined according to specific conditions, and the layout spacing, size and cylinder can be adjusted according to specific working conditions. Quantity; such as figure 2 As shown, the dust removal cylinder is distributed around the cyclone dust collector, and the dust removal cylinder is equipped with a keel, a filter bag and a pulse blowback system. A buffer tank 3 is arranged on the top of the cyclone dust collector, a partition plate 4 is arranged between the buffer tank 3 and the cyclone dust collector, and reinforcing ribs are arranged on the partition board. The top of the cyclone dust collector is provided with an overpressure relief device 5, a first main pipe 6 and a second main pipe 7; one end of the overpressure relief device 5 is locat...

Embodiment 2

[0031] Embodiment 2: The rest of the structure is the same as in Embodiment 1, wherein the first branch pipe 8 and the second branch pipe 9; the first branch pipe includes a valve, a hand hole 81, a large tie rod compensator 82 and a purge and release facility, and the valve includes a butterfly valve 83 and glasses Valve 84, the second branch pipe includes valve, hand hole 91, large tie rod compensator 92 and purge and release facilities, and the valve includes butterfly valve 93 and glasses valve 94.

[0032] The above system is used for dust removal of blast furnace gas. The raw gas enters the first main pipe 6 from the top of the blast furnace, passes through the buffer tank 3, enters the cyclone dust collector 1, and performs the first step of dust removal to remove large particle size dust in the raw gas. Dust content can be reduced to ≤10g / Nm 3 , the first branch pipe 8 of the cyclone dust collector 1 enters the dust removal cylinder 2 of the bag type dust collector, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com