Preparation method of low-carbon environment-friendly snow melting agent

A low-carbon environmental protection, snow-melting agent technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of reducing snow-melting effects and uneven spraying, and achieve high-value utilization, good fluidity, and easy mechanical spraying and the effect of scale operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

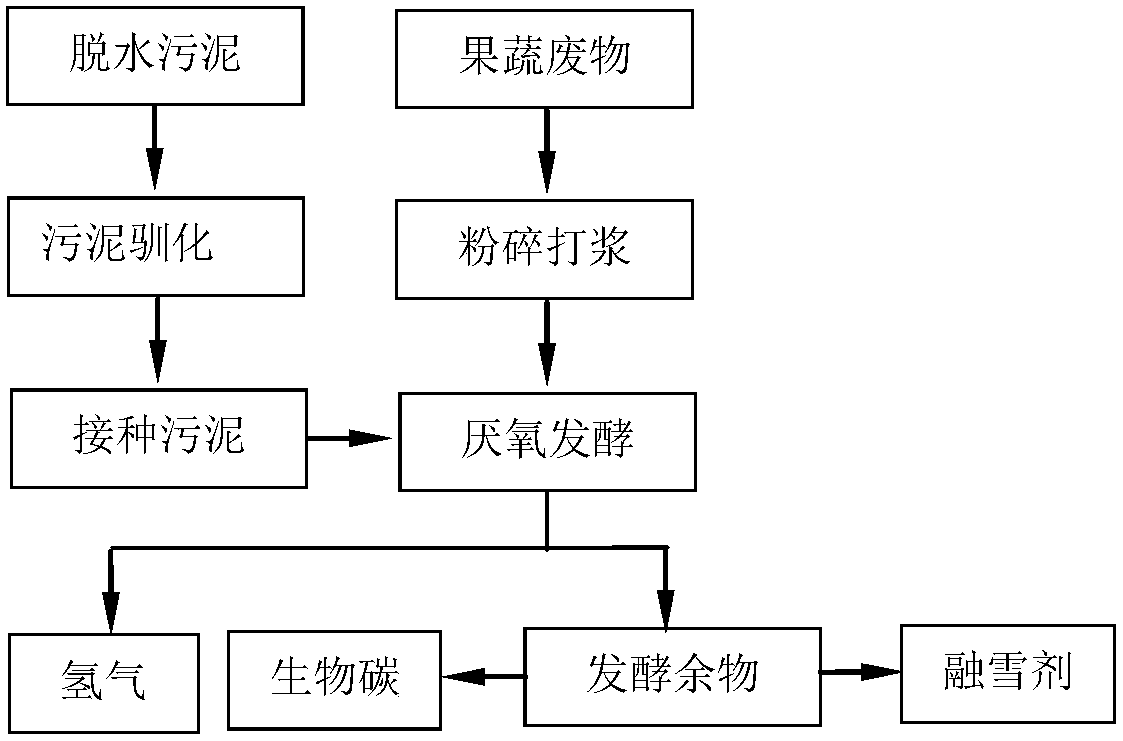

Method used

Image

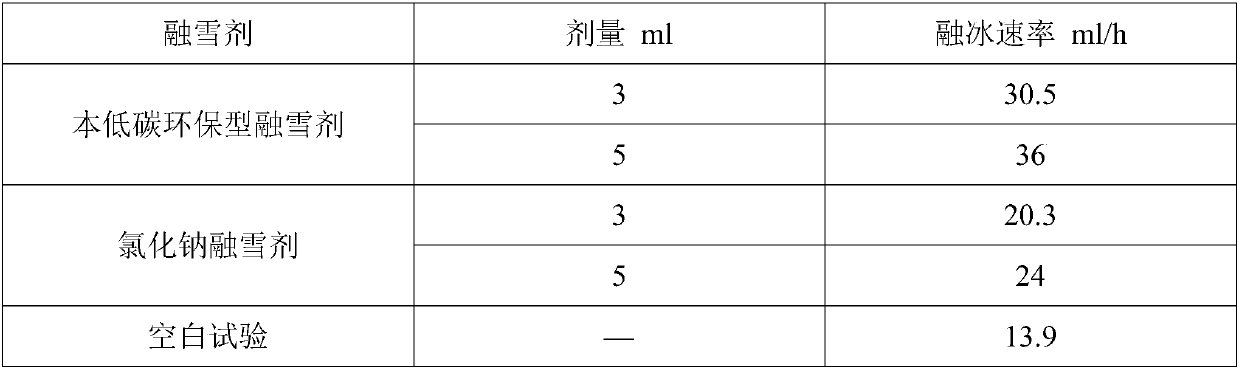

Examples

Embodiment 1

[0047] (1) Preparation of inoculated sludge: Take 500ml of sludge and pour it into a fermentation bottle, heat it in a constant temperature water bath at 85°C for 30min. The sludge comes from the sludge dewatering room of municipal sewage treatment plants or industrial wastewater treatment plants (stations), with a water content of 80% and an organic matter content of 55% in the sludge. Under anaerobic and high temperature (55°C) conditions, the organic load (glucose concentration) was 5g / L, enriched and acclimated for 24h, or until gas production stopped.

[0048] (2) Preparation of the substrate: After washing fruit and vegetable wastes such as apples, bananas, and cabbage, beating is performed to obtain nutrients for fermentation and acid production. The solid content is 10.5%, the volatile components account for 94.3%, and the pH is 6.0.

[0049] (3) Preparation of low-carbon organic mixed acid crude product: Add 500ml of fruit and vegetable slurry to a 1000ml fermentation...

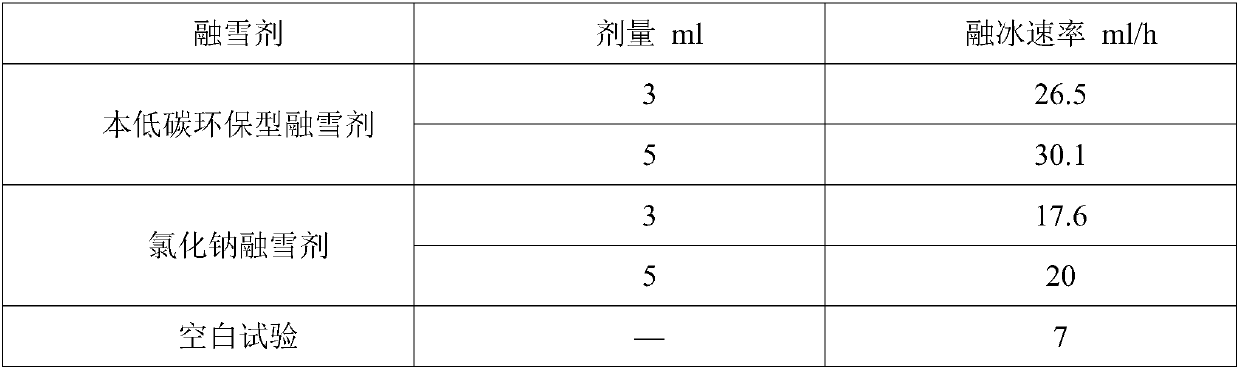

Embodiment 2

[0054] (1) Preparation of inoculated sludge: Take 500ml of sludge and pour it into a fermentation bottle, heat it in a constant temperature water bath at 90°C for 25 minutes. The sludge comes from the sludge dewatering room of municipal sewage treatment plants or industrial wastewater treatment plants (stations), with a water content of 85% and an organic matter content of 70% in the sludge. The organic load (glucose) is 10g / L, and the anaerobic enrichment and acclimatization at 35°C for 40h, or until the gas production stops, the obtained anaerobic activated sludge is the inoculum for the fermentation of fruit and vegetable waste to produce hydrogen.

[0055] (2) Preparation of the substrate: After washing fruit and vegetable wastes such as pineapples, oranges, yams, potatoes, etc., beating is carried out to obtain nutrients for fermentation and acid production. The solid content is 9.5%, the volatile components account for 95%, and the pH is 6.0.

[0056] (3) Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com