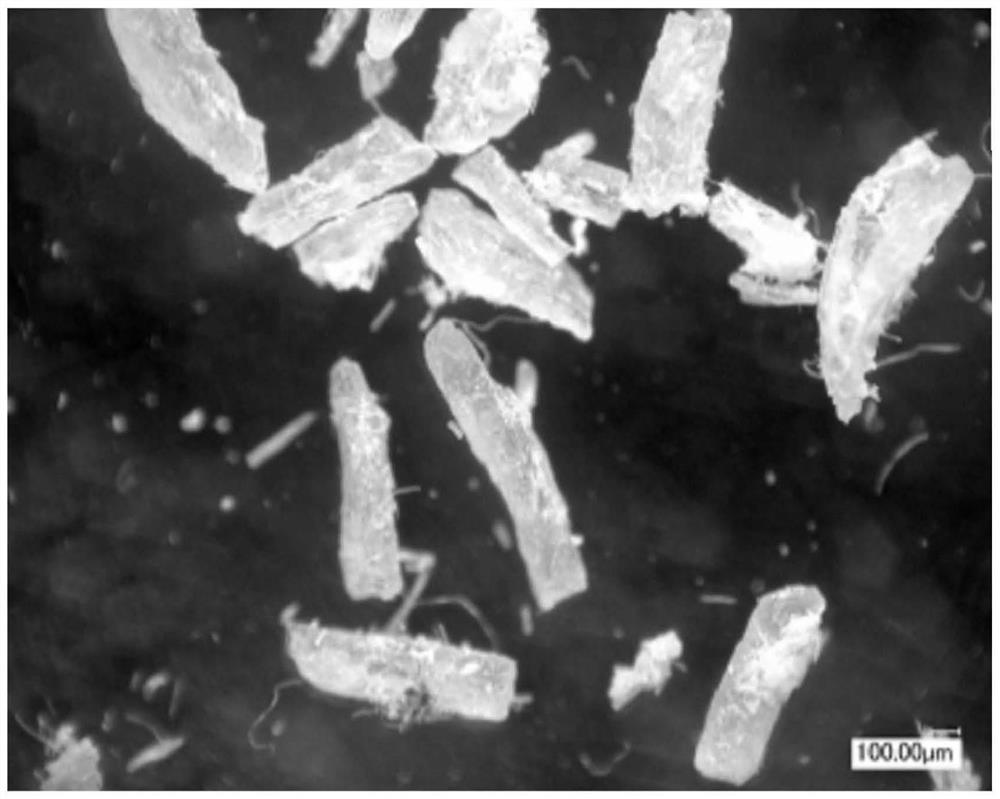

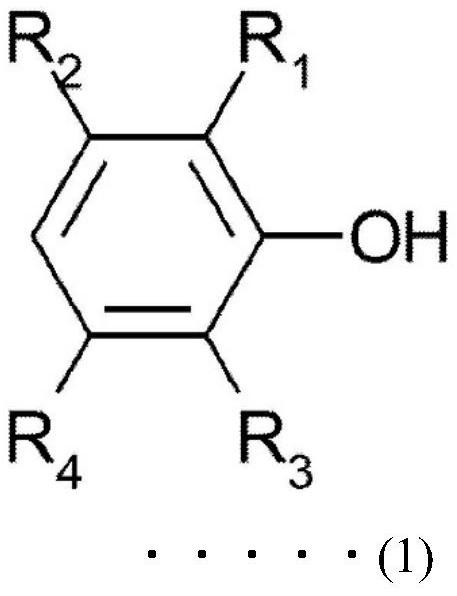

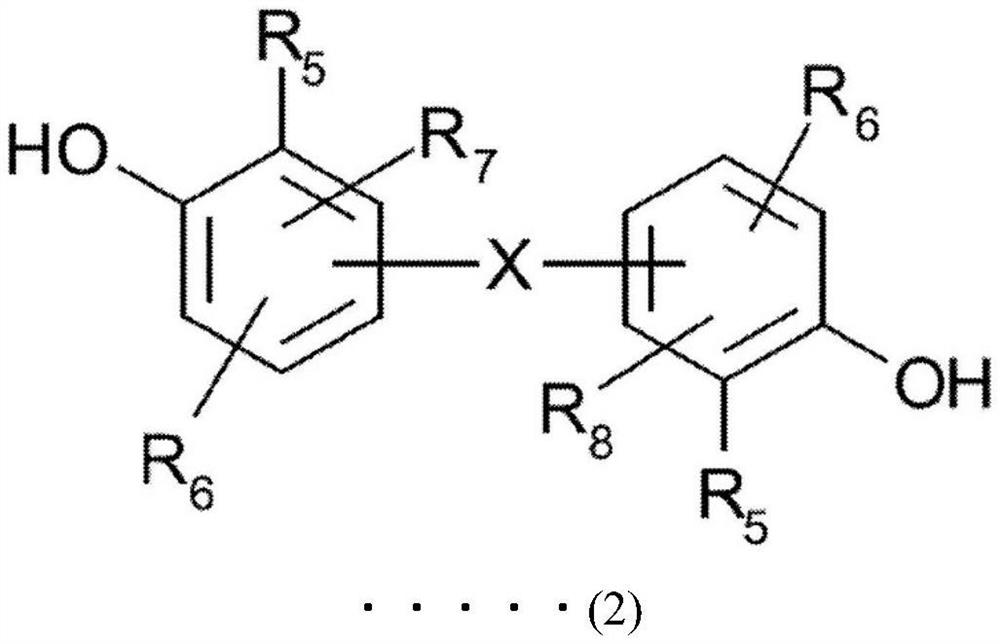

Polyphenylene ether powder and its production method

A manufacturing method and technology for polyphenylene ether, which are applied in the field of polyphenylene ether and its manufacture, can solve the problems of lowering productivity, lowering yield, lowering powder supplying device, etc., and achieves difficult micronization, good handleability, and suppression of jet flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0216] The present embodiment will be specifically described below with reference to specific examples and comparative examples for comparison therewith, but the present embodiment is not limited to the following examples.

[0217] The measurement methods of the physical properties and characteristics used in Examples and Comparative Examples are as follows.

[0218] (1) Determination of number average molecular weight (Mn)

[0219] As a measuring device, a gel permeation chromatograph System 21 manufactured by Showa Denko Co., Ltd. was used to prepare a calibration curve using polystyrene, and the number average molecular weight (Mn) of the obtained polyphenylene ether powder was measured using the calibration curve.

[0220] As standard polystyrenes, polystyrenes having molecular weights of 3,650,000, 2,170,000, 1,090,000, 681,000, 204,000, 52,000, 30,200, 13,800, 3,360, 1,300, and 550 were used.

[0221] As the column, a column in which two K-805L manufactured by Showa Denko...

manufacture example 1

[0294] In a 40-liter jacketed polymerization tank (the bottom of the polymerization tank is equipped with a nozzle for introducing oxygen-containing gas, a turbine impeller and a baffle, and the exhaust line on the top of the polymerization tank is equipped with a reflux cooler), one side is equipped with a 0.5 The flow rate of L / min is blown into nitrogen, while adding 4.57g of divalent copper oxide, 24.18g of 47% by mass hydrogen bromide aqueous solution, 11.00g of di-tert-butylethylenediamine, 62.72g of di-n-butylamine, 149.92 g of butyldimethylamine, 20.65 kg of toluene, and 3.12 kg of 2,6-dimethylphenol were prepared into a uniform solution, and stirred until the inner temperature of the polymerization tank reached 25°C. Next, dry air was introduced from the nozzle into the polymerization tank at a speed of 32.8 NL / min to initiate polymerization. Dry air was blown for 140 minutes to obtain a polymerization mixture. In addition, during polymerization, internal temperature...

manufacture example 2

[0298] Molecular weight was controlled by changing the polymerization time for 125 minutes for the ventilation time of dry air. Production was carried out in the same manner as in Production Example 1 under other conditions to obtain a polymer solution. The obtained polymer solution was referred to as polymer solution (2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com