High-strength interpenetrating-polymer-network type water-absorbent resin, and preparation method thereof

An interpenetrating network type, water-absorbing resin technology, applied in the field of polymer material preparation, can solve the problems of limited strength improvement of cross-linking agent, complicated process conditions, complex cross-linking agent, etc., and achieves improved toughness and strength, simple raw materials, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

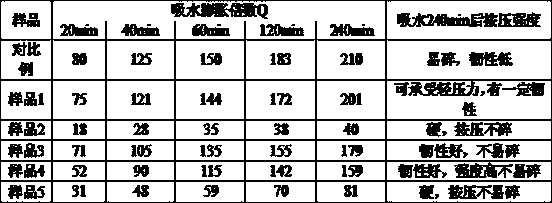

Examples

Embodiment 1

[0027] After dissolving 2 parts of polyvinyl alcohol in water, continue to add 20 parts of acrylamide, 10 parts of acrylic acid with a neutralization degree of 50%, and 5 parts of acryloyloxyethyl dimethyl benzyl ammonium chloride (other polymerizable monomers) , 0.05 parts of N,N-methylenebisacrylamide (cross-linking agent A), 0.2 parts of glutaraldehyde (cross-linking agent B), stirred evenly and dissolved, then transferred the reaction liquid to a reactor with stirring, condensation and thermometer In the process, nitrogen was passed for 30 minutes to remove oxygen, and then 0.05 parts of ammonium persulfate was added in the nitrogen atmosphere, and the temperature was adjusted to 60°C for reaction. After the viscosity was increased, the stirring was stopped and maintained for 2 hours. After the reaction, the product was taken out, cut and granulated, 105 After drying at ℃, it was crushed to obtain granular water-absorbing resin.

Embodiment 2

[0029] After dissolving 5 parts of polyvinyl alcohol in water, continue to add 10 parts of acrylamide, 2 parts of acrylic acid with a neutralization degree of 80%, 1 part of hydroxyethyl methacrylate (other polymerizable monomers), 0.01 part of dimethyl dimethacrylate Allyl ammonium chloride (cross-linking agent A), 0.8 parts of glutaraldehyde (cross-linking agent B), stirred evenly and dissolved, then transferred the reaction solution to a reactor with stirring, condensation and thermometer, and nitrogen for 30 minutes to remove After oxygen, add 0.01 part of potassium persulfate in a nitrogen atmosphere, adjust the temperature to 60°C for reaction, stop stirring after increasing viscosity and maintain it for 6 hours. After the reaction, take out the product, cut it, granulate it, dry it at 105°C, and crush it to obtain granular water-absorbing resin.

Embodiment 3

[0031] After dissolving 3 parts of polyvinyl alcohol in water, continue to add 15 parts of acrylamide, 6 parts of acrylic acid with a neutralization degree of 70%, 3 parts of vinyl acetate (other polymerizable monomers), 0.03 parts of N,N-methylene Bisacrylamide (cross-linking agent A), 0.5 parts of glutaraldehyde (cross-linking agent B), stirred evenly and dissolved, then transferred the reaction solution to a reactor equipped with stirring, condensation and thermometer, passed nitrogen gas for 30 minutes to deoxygenate Add 0.03 parts of ammonium persulfate in a nitrogen atmosphere, adjust the temperature to 30°C for reaction, stop stirring after increasing the viscosity and maintain it for 6 hours. After the reaction, the product is taken out, cut, granulated, dried at 105°C and crushed to obtain granular water-absorbent resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com