Substrate fermentation device with interlayer, gas chimneys and movable bottom doors

A fermentation device and interlayer technology, applied in the field of biological fermentation engineering, can solve the problems of multi-mechanical power and energy consumption, increased investment, short fermentation cycle, etc., and achieve the effect of good social pulling effect, simplified process flow, and large fermentation scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

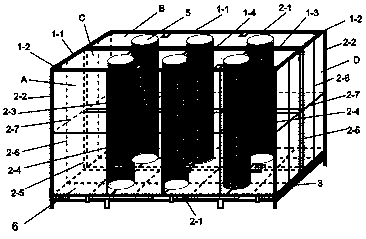

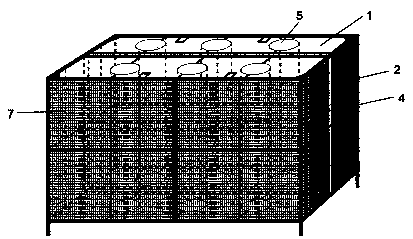

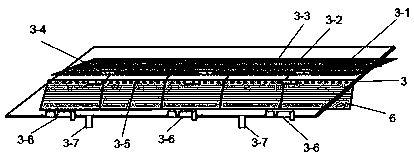

[0036] A substrate fermentation device with interlayer, gas chimney and movable bottom door. The device is a steel fence frame structure, which consists of three parts: frame mouth (1), frame body (2) and frame bottom (3). It is: the device also has a sandwich (4), an air chimney (5) and a movable bottom door (6); the sandwich (4) is a double-sided galvanized steel wire mesh panel with an interval of 70mm set in the middle of the device, the galvanized The density of the steel mesh plate is 16 mesh, welded on the square pipe skeleton, and the device is divided into two silos to form a hollow ventilation layer; the gas chimney (5) is set in the silo divided into 6 through Hollow air-permeable cylinder holes in the frame mouth (1) and frame bottom (3); it is a cylinder with a diameter of 180 mm made of galvanized steel mesh with a density of 16 mesh, and the cylinder mouth and bottom are respectively connected to the frame mouth (1), The frame bottom (3) is connected. The movab...

Embodiment 2

[0041] A substrate fermentation device with interlayer, gas chimney and movable bottom door. The device is a steel fence frame structure, which consists of three parts: frame mouth (1), frame body (2) and frame bottom (3). The reason is: the device also has a sandwich (4), an air chimney (5) and a movable bottom door (6); the sandwich (4) is a double-sided galvanized steel wire mesh panel with an interval of 50mm set in the middle of the device, the galvanized The density of the steel mesh plate is 20 mesh, which is welded on the square pipe skeleton, and the device is divided into 4 silos to form a hollow ventilation layer; the gas chimney (5) is set in the silos divided into 4 through Hollow air-permeable cylindrical holes in the frame mouth (1) and frame bottom (3); it is a cylinder with a diameter of 200mm made of galvanized steel mesh with a density of 20 mesh, and the cylinder mouth and bottom are respectively connected to the frame mouth (1), The frame bottom (3) is con...

Embodiment 3

[0046] A substrate fermentation device with interlayer, gas chimney and movable bottom door. The device is a steel fence frame structure, which consists of three parts: frame mouth (1), frame body (2) and frame bottom (3). The reason is: the device also has a sandwich (4), an air chimney (5) and a movable bottom door (6); the sandwich (4) is a double-sided galvanized steel wire mesh panel with an interval of 80mm set in the middle of the device, the galvanized The density of the steel mesh plate is 10 mesh, welded on the square pipe skeleton, and the device is divided into two silos to form a hollow ventilation layer; the gas chimney (5) is set in the silos divided into 6 through The hollow air-permeable cylinder hole of the frame mouth (1) and the frame bottom (3); it is a cylinder with a diameter of 200mm made of galvanized steel mesh with a density of 10 mesh, and the cylinder mouth and bottom are respectively connected to the frame mouth (1), The frame bottom (3) is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com