Plastic part grinding and polishing equipment

A technology for parts and plastics, applied in the field of automobile plastic parts processing, can solve the problems of poor uniformity and high grinding cost, and achieve the effect of high processing efficiency and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

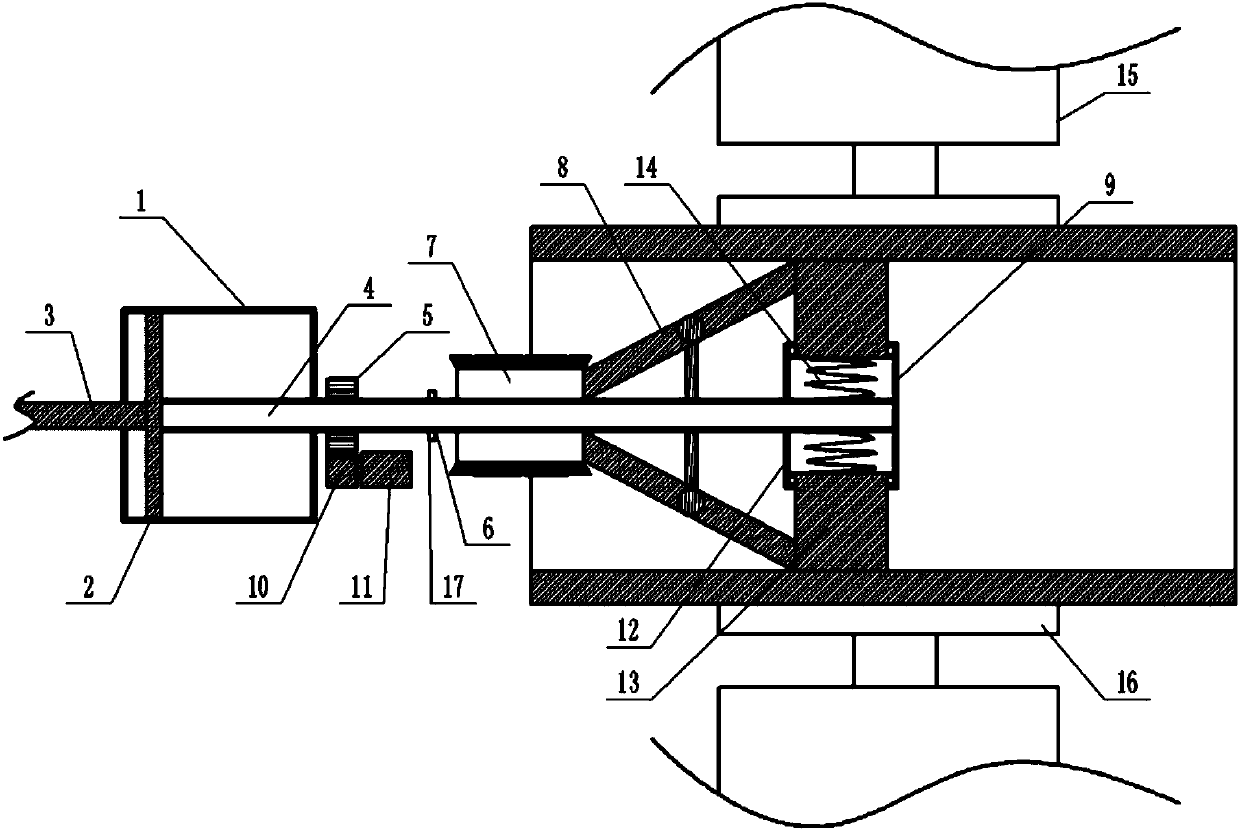

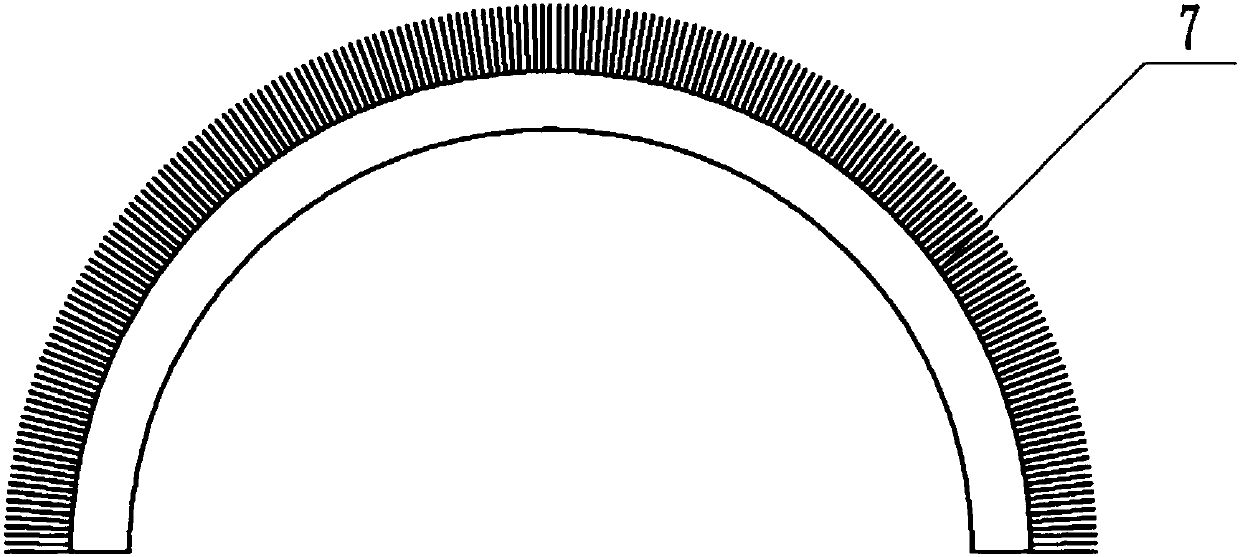

[0019] The reference signs in the drawings of the description include: propulsion cylinder 1, piston plate 2, piston rod 3, hollow shaft 4, spline sleeve 5, adsorption port 6, electrostatic brush 7, support lever 8, grinding and polishing set 9, gear 10. Motor 11, guide sleeve 12, polishing block 13, tension spring 14, clamping cylinder 15, clamping block 16, adsorption channel 17.

[0020] The embodiment of plastic parts grinding and polishing equipment is basically as attached figure 1 And attached figure 2 Shown: including the frame and the parts clamping device and the grinding and polishing device on the frame; the grinding and polishing device includes a working propulsion cylinder horizontally arranged on the frame, and one side of the piston plate of the propulsion cylinder is fixedly connected to the piston rod , the other side is rotatably connected with a hollow shaft, the hollow sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com