Method for manufacturing wax pattern for golf club head

A golf club head and a manufacturing method, which are applied in the field of wax mold manufacturing, can solve problems such as insufficient connection strength, and achieve the effects of reducing deformation time and increasing initial speed of impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

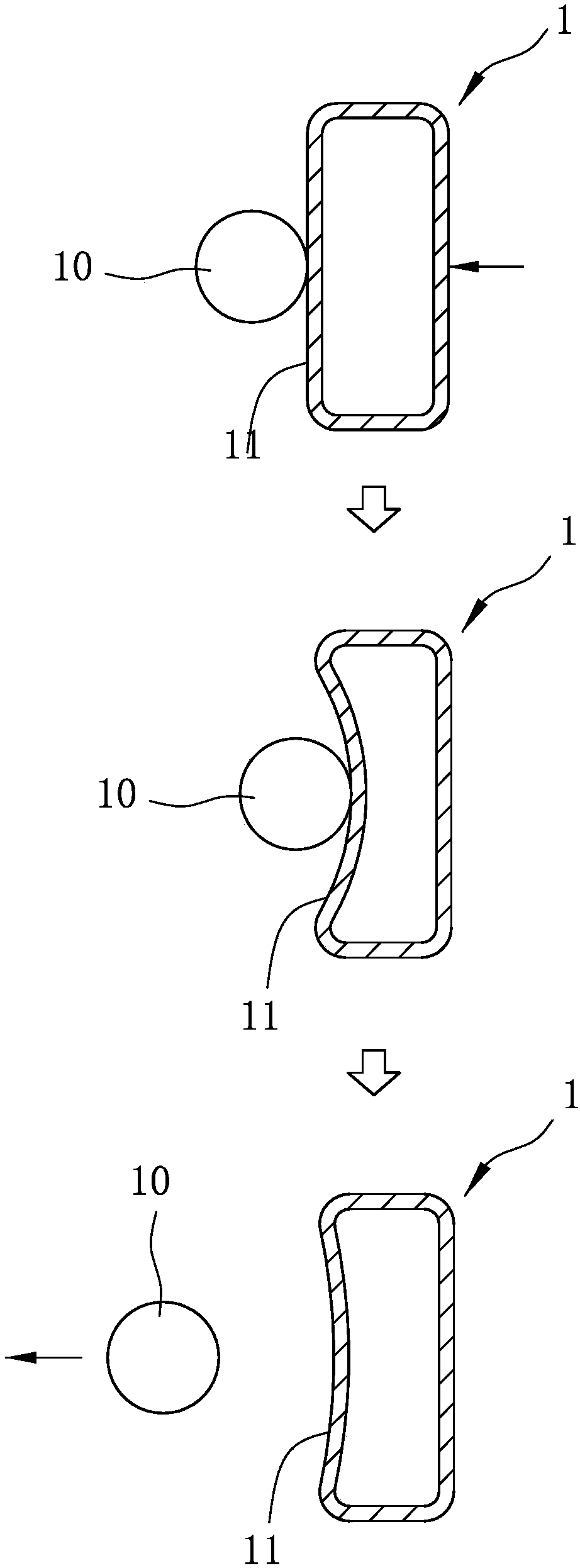

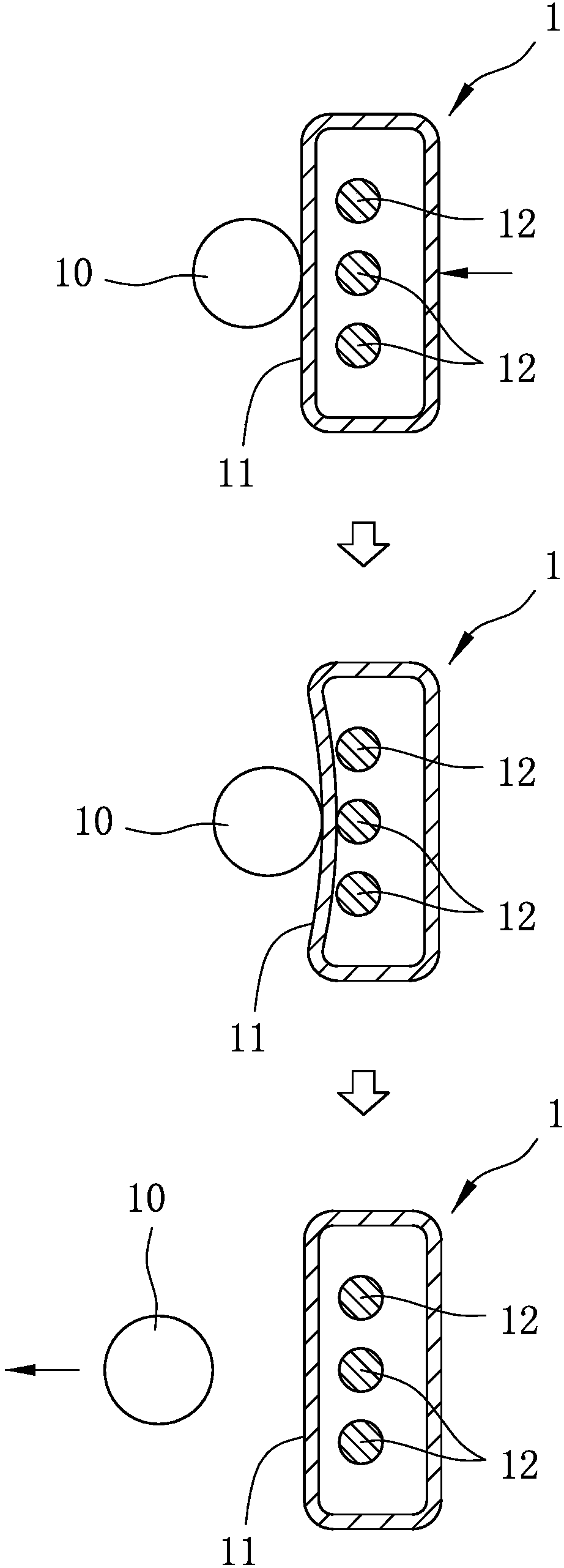

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

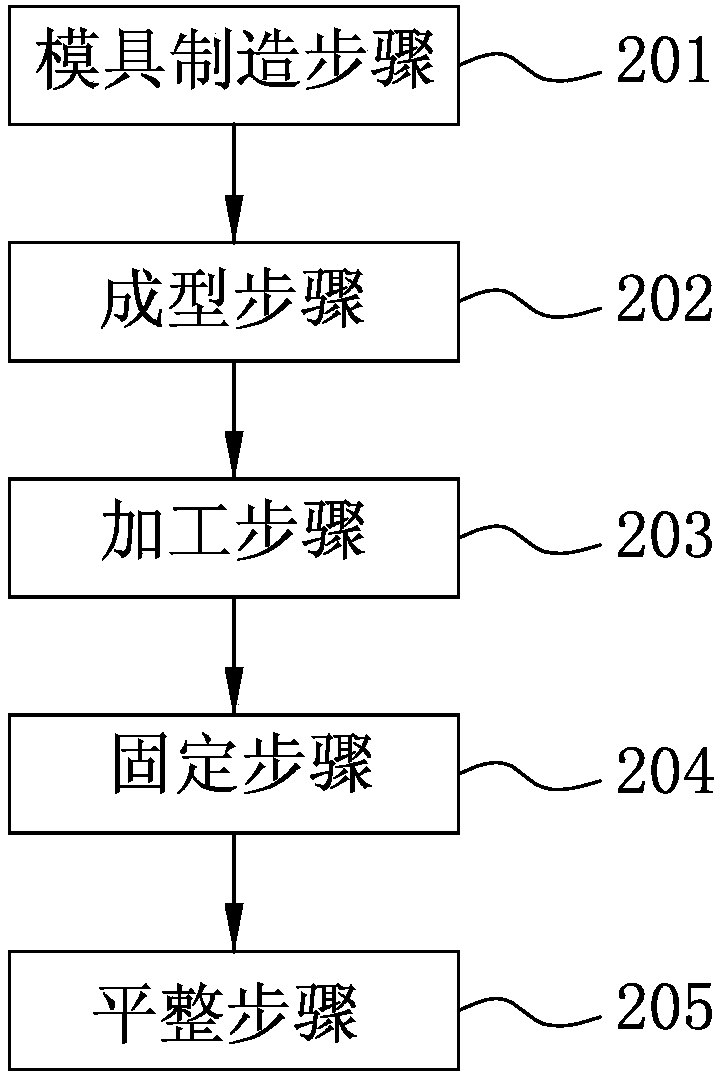

[0032] refer to image 3 , a first embodiment of the method for manufacturing the wax model 3 of the golf club head 2 of the present invention includes a mold manufacturing step 201 , a molding step 202 , a processing step 203 , a fixing step 204 , and a flattening step 205 .

[0033] refer to image 3 and Figure 4 , in the mold manufacturing step 201, a blank mold of a corresponding shape (not shown) is first manufactured with a processing tool according to the shape of the club head to be manufactured, and then the blank mold is used as a reference shape to be processed by electric discharge machining. A mold cavity corresponding to the shape of the blank mold is produced in a mold (not shown) with upper and lower molds. In the first embodiment, the blank mold is a copper mold. In the forming step 202, melted wax is poured into the cavity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com