Chamber Nested Bolt and Oval Rifling

a chamber and bolt technology, applied in the direction of breech mechanism, weapon components, weapon parts, etc., can solve the problems of not being used with guns designed to shoot high pressured ammunition or large projectiles, reducing the design accuracy of guns, and reducing the reliability of simple blowback guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

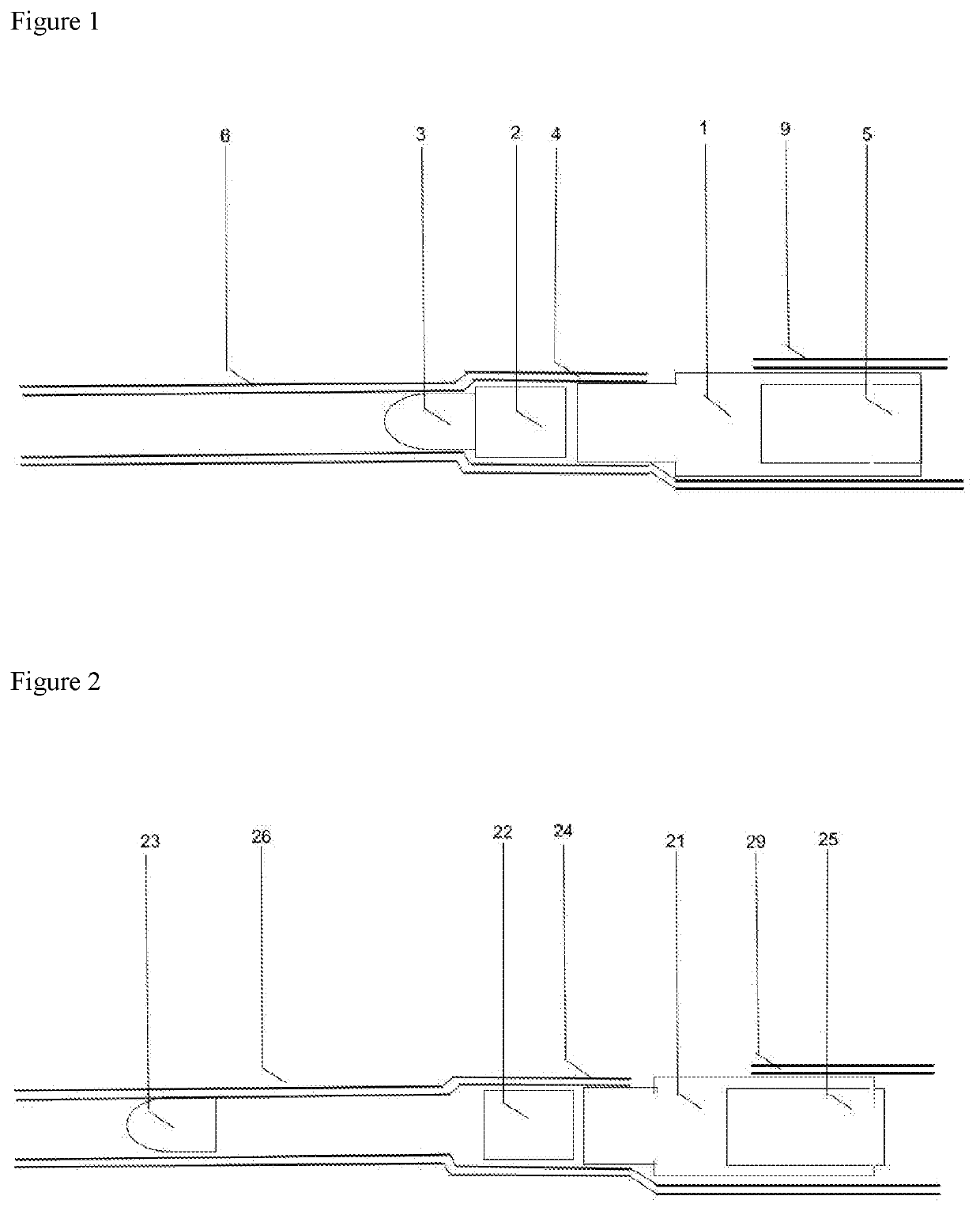

[0017]FIG. 1 represents the most basic concept of a chamber nested bolt. The bolt carrier (1), the cartridge (2), and the bullet (3) are at rest prior to firing nested inside the chamber of the firearm. The bullet is at the end of the camber (4) protruding into the barrel (6), and the bolt carrier's end is also located inside of the chamber so that when it recoils backwards, the gas is not instantly released. A spring or other return force (5) is holding the bolt carrier shut until the firearm is fired. A receiver (9) holds the bolt in place while it is at rest, and guides it when it recoils.

[0018]In addition to the return force (5), the firearm can incorporate additional means of controlling the speed of the bolt's recoil. This could be done using a damper or dashpot, but many devices are suitable for controlling the bolt's recoil after firing. By including a delayed blowback devices (such as gas operated cycles or delayed blowback so that the speed of the bolt's recoil could be mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com