Preparation method of flower-shaped Cu2SnS3 flexible supercapacitor electrode materials

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc. It can solve the problems of poor crystallinity and complicated manufacturing process, and achieve the effect of high crystallinity and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

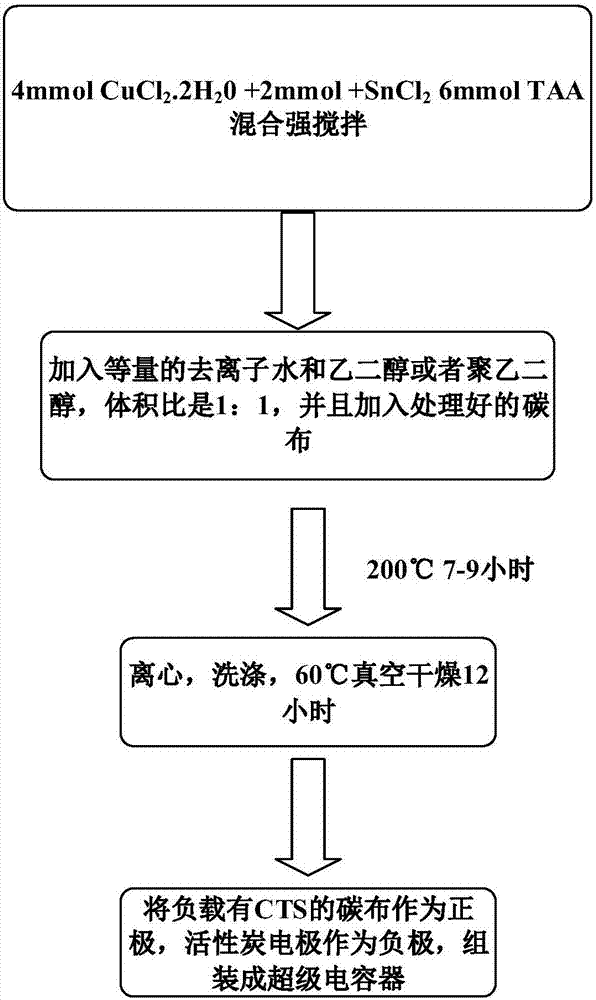

[0017] Step 1: Flower-like Cu 2 SnS 3 Synthesis of electrode materials: 4mmol CuCl 2 .2H 2 0,2mmol SnCl 4 and 6mmolTAA (thioacetamide), fully mixed evenly, stirred strongly for 2 hours, and then put the treated carbon cloth with an area of 2cm*2cm into the reaction kettle. Then it is transferred to the reactor, add an equal amount of deionized water and ethylene glycol (or polyethylene glycol) respectively, so that the volume ratio of the two is 1:1, the reactor is transferred to the incubator, and The temperature was adjusted to 200° C., and the temperature was maintained for 9 hours. and other prepared Cu 2 SnS 3 Compared with the reaction, the reaction time is shortened and the experimental cycle is reduced.

[0018] Step 2: After the reaction kettle was cooled to room temperature, the obtained product was centrifuged and washed three times with deionized water and ethanol, and the obtained carbon cloth was rinsed with deionized water and absolute ethanol respectiv...

Embodiment 2

[0022] Step 1: Add CuCl 2 .2H 2 0. SnCl 4 , Thioacetamide is evenly mixed in a molar ratio of 2:1:3, then soak the clean carbon cloth in the mixed solution;

[0023] Step 2: Add deionized water and ethylene glycol mixed solution with a volume ratio of 1:1, the volume of the added deionized water and ethylene glycol mixed solution is the same as the volume of the mixed solution obtained in step 1, and mix well;

[0024] Step 3: Place the solution obtained in Step 2 in a dry environment at high pressure and 200°C, and dry it for 7 hours;

[0025] Step 4: After the reaction, the carbon cloth is attached with flower-like Cu 2 SnS 3 , washed with deionized water and absolute ethanol, and the washed carbon was dried in a vacuum environment at 60°C;

[0026] Step 5: Dry the finished Cu 2 SnS 3 The carbon cloth is used as the positive and negative electrodes of the supercapacitor.

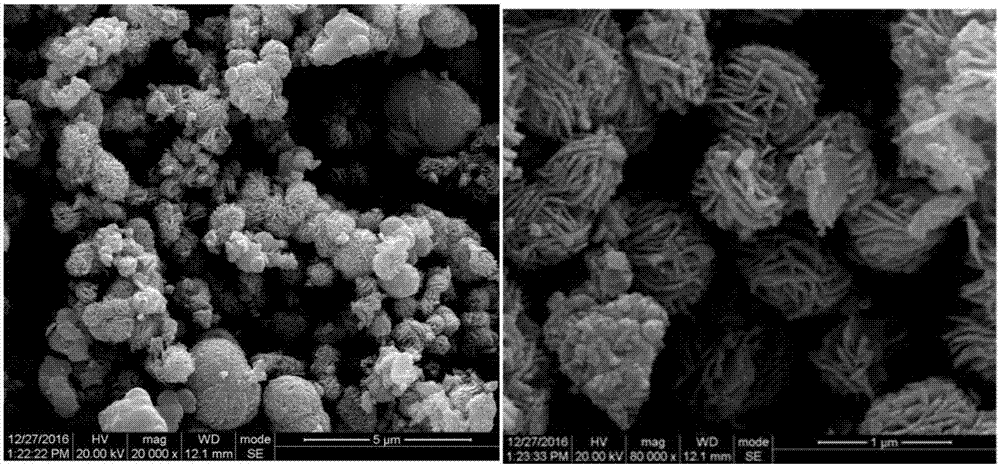

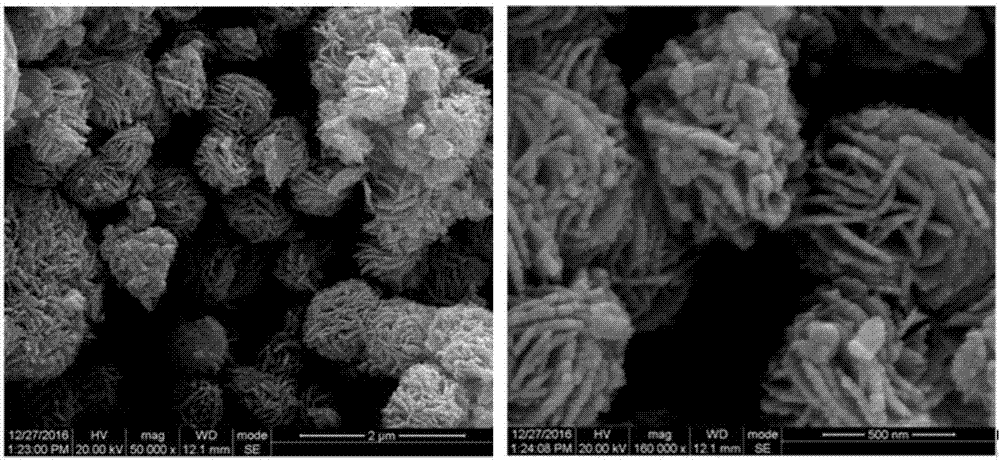

[0027] figure 2 , image 3 : is the SEM picture of prepared material, as shown in the Cu pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com