Gear shaft of reduction gear of new-energy automobile and manufacturing technology for gear shaft

A technology of new energy vehicles and reducers, which is applied to belts/chains/gears, mechanical equipment, transmission parts, etc. It can solve the problems of low internal structure density, large cutting processing volume, poor impact resistance, etc., and achieve production efficiency High, high product mechanical properties, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

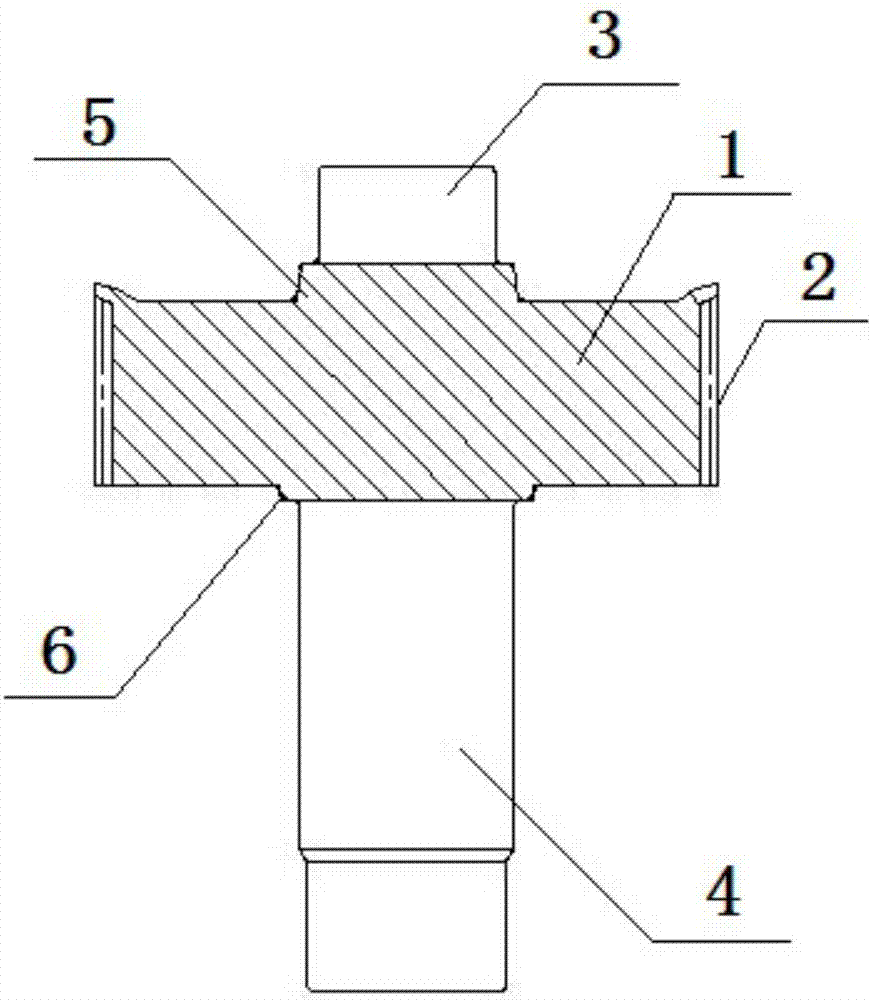

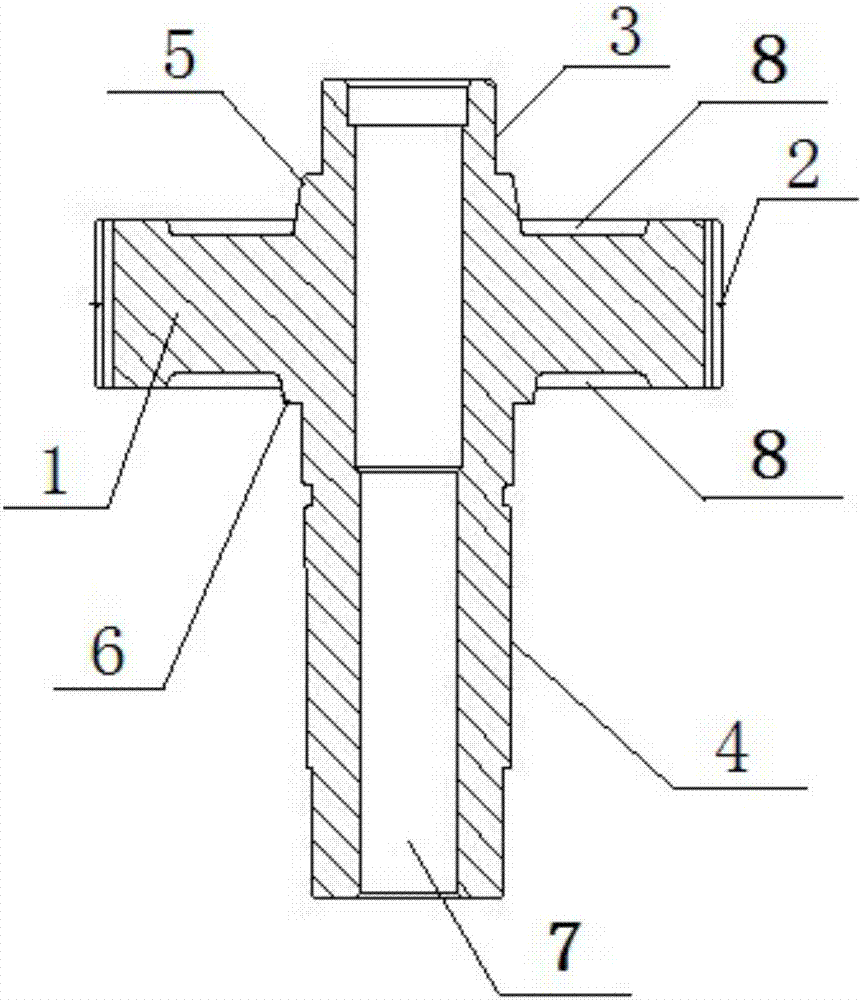

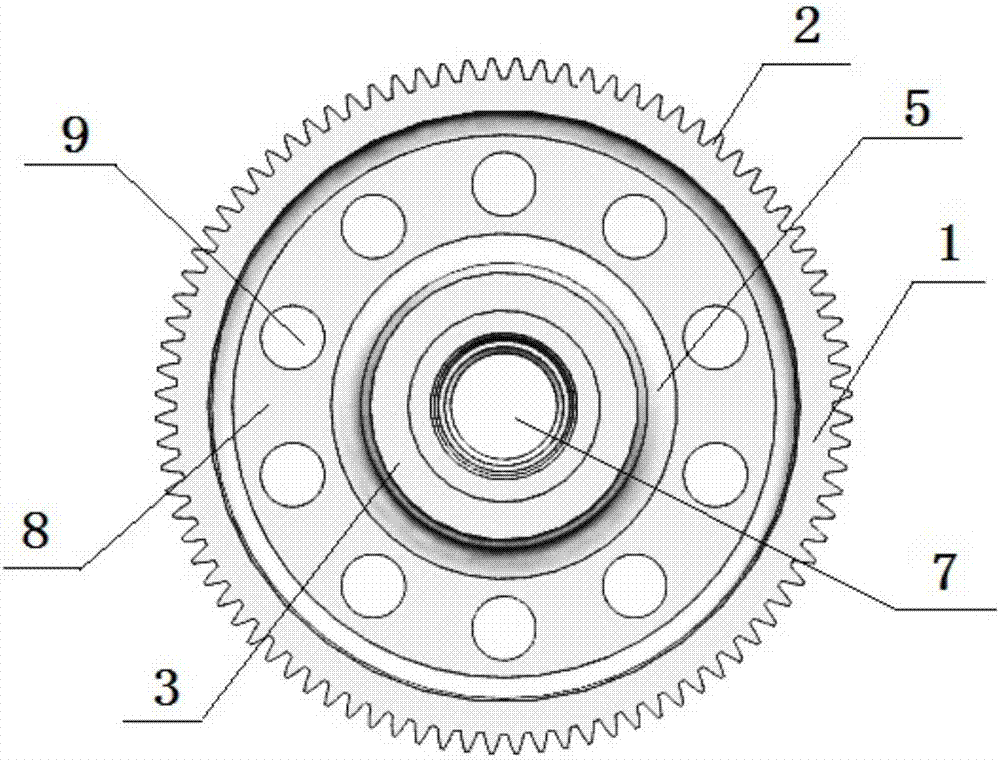

[0021] Example: see figure 1 , figure 2 and image 3 As shown, a new energy vehicle reducer gear shaft includes a rod part and a disc part 1. The disc part 1 is a cylindrical structure and the outer wall is provided with a toothed structure 2. The rod part is vertically arranged at the center of the disc part and divided into upper Rod 3 and lower rod 4, upper transition section 5 and lower transition section 6 are respectively arranged between the upper rod 3 and the lower rod 4 of the disk part and the rod part, and the diameters of the upper and lower transition sections 5 and 6 are respectively larger than the upper rod 3 , the diameter of the lower rod 4, the lower rod 4 is a circular platform structure with a decreasing trend in diameter from the plate to the bottom. A central through hole 7 is formed in the center of the disc portion 1, a groove ring 8 is formed on the upper and lower end surfaces of the disk part 1, and ten weight-reducing holes 9 are uniformly dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com