Split bolt assembly and method for mounting wall formwork

A technology of pulling bolts and kits, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., which can solve the problem that it is difficult to ensure the quality of wall bolt holes and affect the wall. Forming quality, waste of human resources and other issues, to avoid labor waste and quality risks, improve construction quality, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

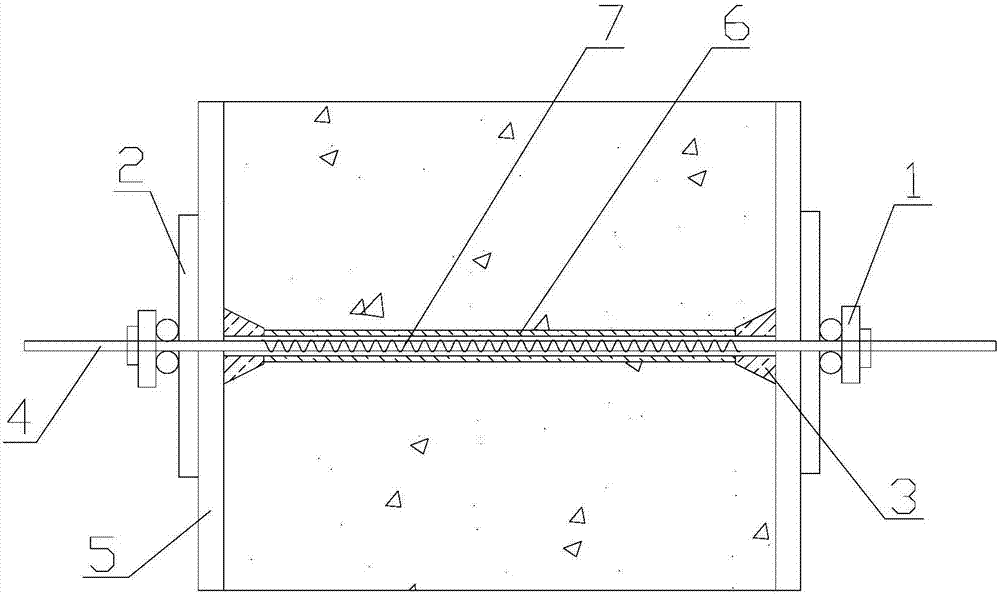

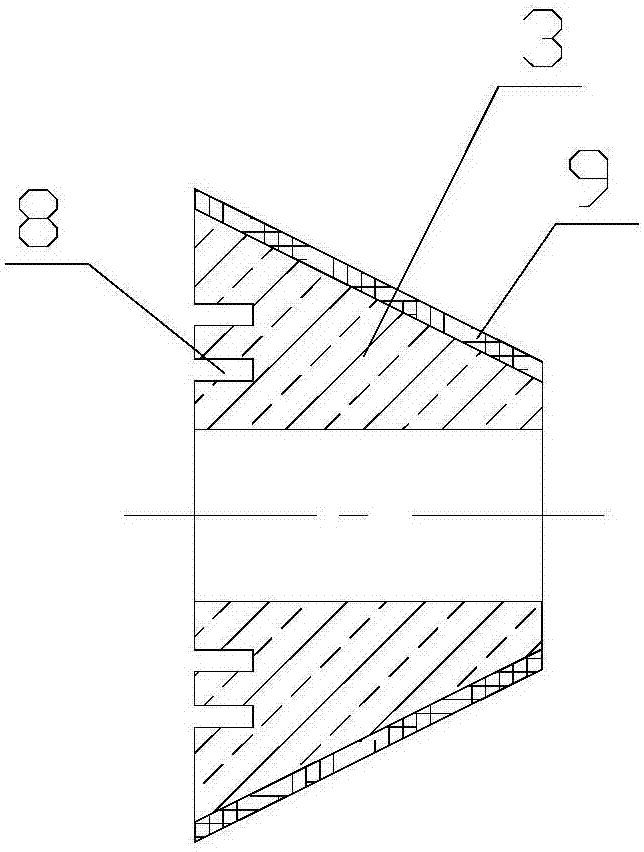

[0030] A pair of pull bolt kits, comprising a pull bolt rod 4, a fastening nut 1, and a casing 6, the pull bolt rod 4 is set in the casing 6, and the two ends of the pull bolt rod 4 are provided with a fastening nut 1, Both ends of the casing 6 are provided with a tapered plastic hole-forming pad 3 , and a backing plate 2 is provided between the tapered plastic hole-forming pad 3 and the fastening nut 1 .

[0031] The middle part of the pull bolt rod 4 is wound with a rope 7, and the rope 1 is a hemp rope with a diameter of 1 mm. The large end face of the tapered plastic hole-forming pad 3 is provided with 4 grooves 8, and the outer surface of the tapered plastic hole-forming pad 3 is covered with a woven cloth 9, and the woven cloth is gauze.

Embodiment 2

[0033] A pair of pull bolt kits, comprising a pull bolt rod 4, a fastening nut 1, and a casing 6, the pull bolt rod 4 is set in the casing 6, and the two ends of the pull bolt rod 4 are provided with a fastening nut 1, Both ends of the casing 6 are provided with a tapered plastic hole-forming pad 3 , and a backing plate 2 is provided between the tapered plastic hole-forming pad 3 and the fastening nut 1 .

[0034] The middle part of the pull bolt rod 4 is wound with a wire rope 7, and the wire rope 1 is a cotton rope with a diameter of 1.2 mm. Conical plastic hole-forming pad 3 large end faces are provided with 4 grooves 8, and the outer surface of conical plastic hole-forming pad 3 is covered with woven cloth 9, and the woven cloth is hemp sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com