Molybdenum disulfide and titanium dioxide-modified ferroferric oxide nanometer composite material

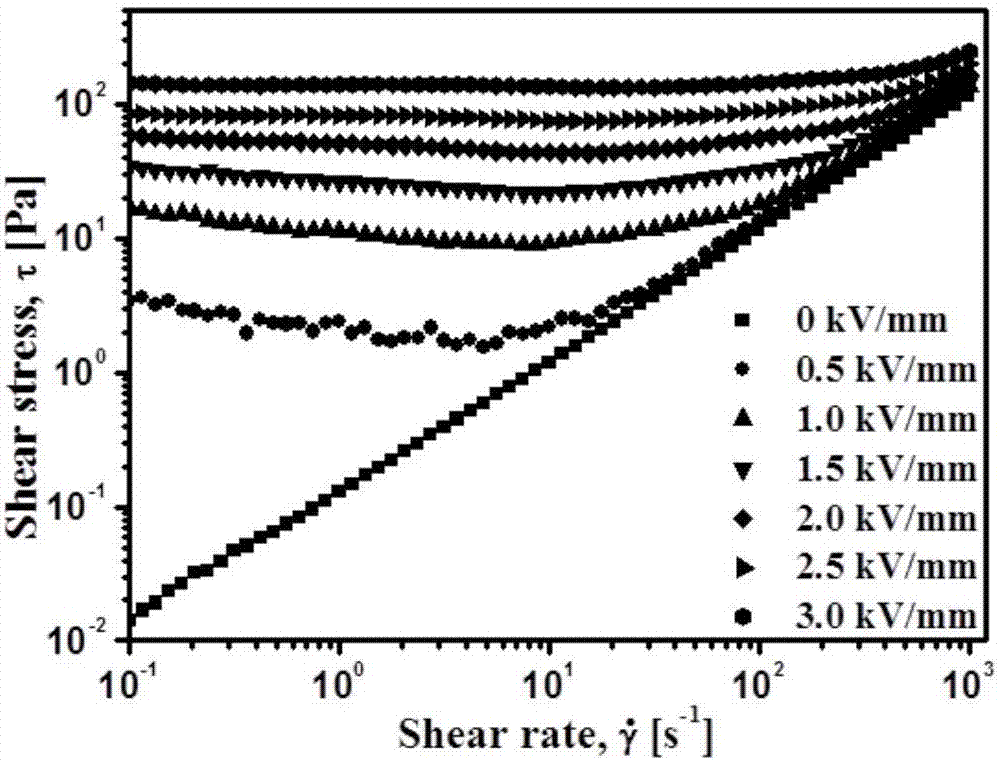

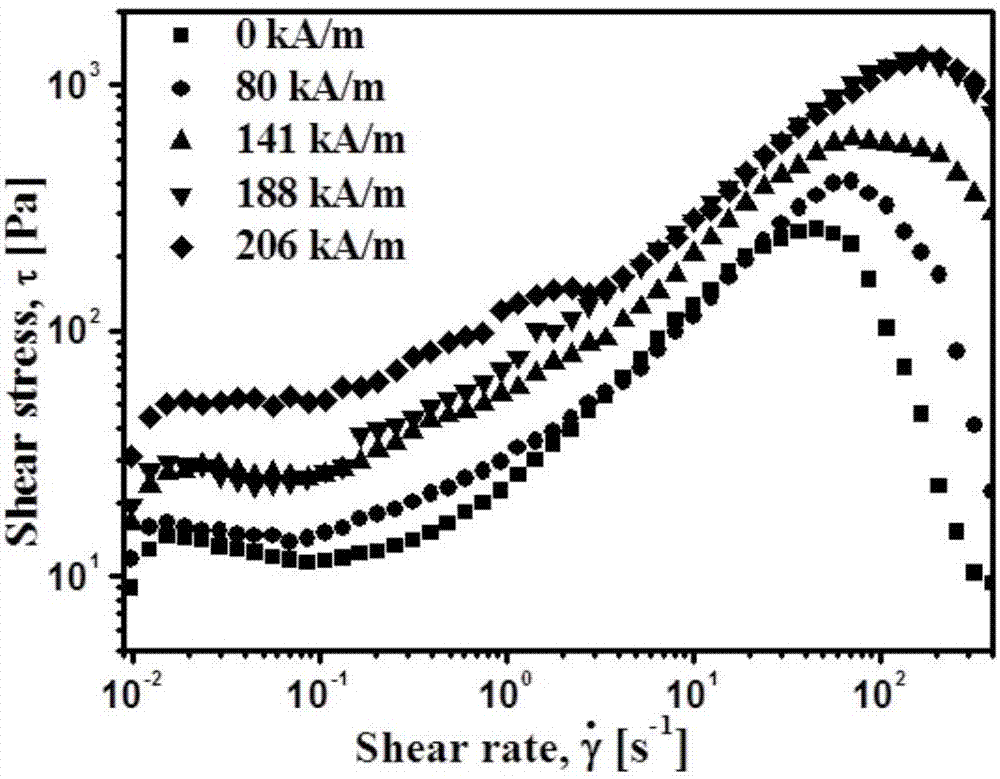

A nano-composite material, ferric oxide technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the lack of effective mechanisms for electrorheological effects and magnetorheological effects, limit the wide application of electrorheological fluids, and limit magnetic currents Problems such as the commercial application of variable fluids, to achieve excellent electrorheological properties, wide application value, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

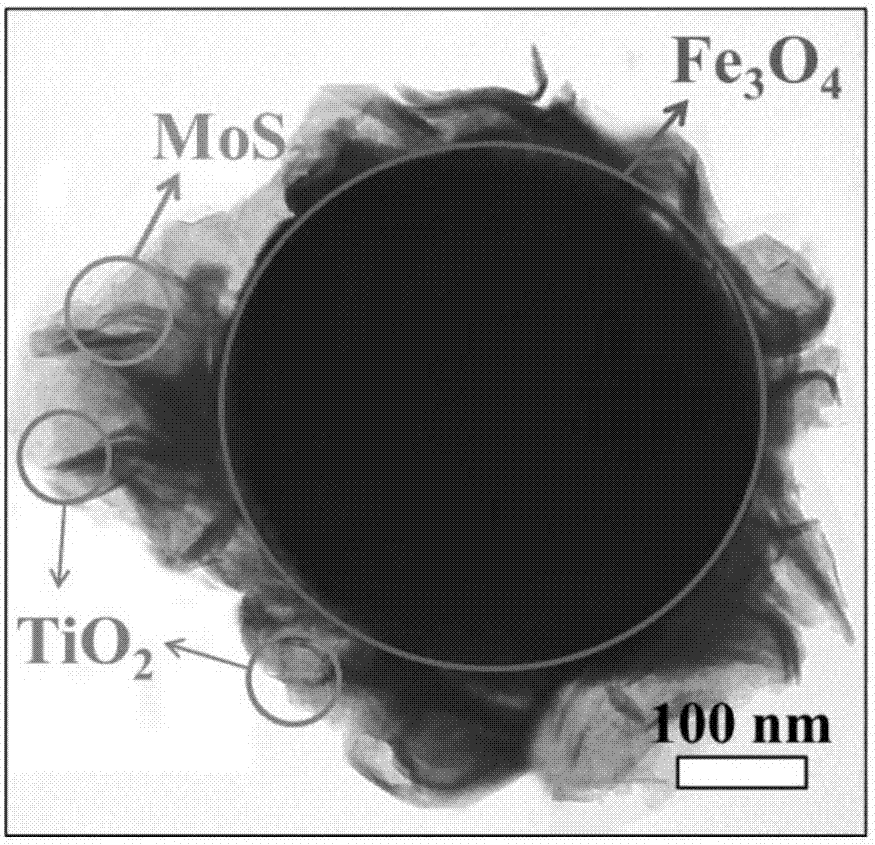

[0018] The preparation process of the shear-thinning electromagnetic rheological material involved in this embodiment includes the following steps:

[0019] (1) first weigh 3.258g of ferric chloride hexahydrate, 10.8g of anhydrous sodium acetate and 0.751g of sodium citrate dihydrate with an electronic balance, then measure 123ml of ethylene glycol with a graduated cylinder, place it in Mix in a 250ml beaker, stir magnetically for 2h at room temperature to obtain a yellow mixed solution, then transfer the mixed solution to a 200ml reaction kettle, heat it with water at 200°C for 10h, after the reaction is completed, the obtained black product is slowly cooled to room temperature, and then The black product is washed with deionized water and ethanol for 5 to 6 times and then freeze-dried to obtain ferric oxide particles;

[0020] (2) Weigh 0.35g of ammonium molybdate tetrahydrate and 0.76g of thiourea with an electronic balance and place it in a 50ml beaker, add 10ml of deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com