A kind of far-infrared heat conduction paste and its preparation method and application

A far-infrared and far-infrared powder technology, which is applied in applications, household utensils, inks, etc., can solve the problems of not having the ability to release hydroxyl anions for antibacterial, antibacterial and air purification, the far-infrared radiation rate is not high enough, and the effect of physical therapy and health care is low. , to achieve good self-limiting temperature effect, strong radiation effect and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

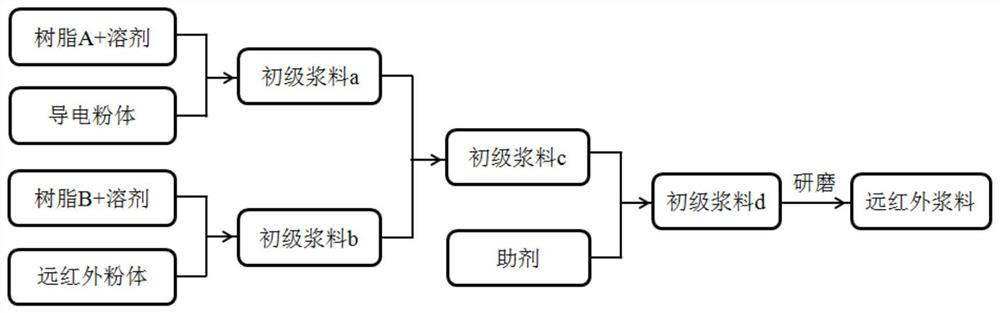

Method used

Image

Examples

preparation example Construction

[0090] As a preferred technical solution of the present invention, the preparation method of the pyrrole-modified far-infrared powder at least includes the following steps:

[0091] Dissolve 0.01g of cetyltrimethylammonium bromide in 30mL of deionized water, add 3g of the far-infrared powder into the solution, ultrasonically disperse for 30-60min, add 80μL of pyrrole, and stir for 10min; 5 mL of 1 mol / L hydrochloric acid aqueous solution containing 0.2 g of ammonium persulfate was gradually added dropwise to the above solution, reacted under ice bath for 10 h, added 2 mL of methanol to terminate the reaction, filtered with suction, and washed the filtrate repeatedly with methanol and distilled water until pH = 7. Vacuum-dry at 60°C for 12 hours to obtain the pyrrole-modified far-infrared powder.

[0092] Cetyltrimethylammonium bromide, CAS: 57-09-0, was purchased from Sinopharm Chemical Reagent Co., Ltd.

[0093] Pyrrole, CAS: 109-97-7, purchased from Sinopharm Chemical Reage...

Embodiment 1

[0132] A far-infrared heat-conducting paste, which comprises at least the following components in parts by weight: 7 parts by weight of resin binder A; 1 part by weight of resin binder B; 18 parts by weight of conductive filler; 3 parts by weight of far-infrared powder; Agent 6 parts by weight; Solvent 19 parts by weight.

[0133] The far-infrared powder is pyrrole-modified far-infrared powder.

[0134] The preparation method of the pyrrole-modified far-infrared powder at least comprises the following steps:

[0135] Dissolve 0.01g of cetyltrimethylammonium bromide in 30mL of deionized water, add 3g of the far-infrared powder into the solution, ultrasonically disperse for 50min, add 80μL of pyrrole, and stir for 10min; Add 5 mL of 1 mol / L hydrochloric acid aqueous solution containing 0.2 g of ammonium persulfate gradually to the above solution dropwise, react in an ice bath for 10 h, add 2 mL of methanol to terminate the reaction, filter with suction, and wash the filtrate re...

Embodiment 2

[0144] A kind of far-infrared heat-conducting slurry, by weight, at least includes the following components: 15 parts by weight of resin binder A; 6 parts by weight of resin binder B; 30 parts by weight of conductive filler; 12 parts by weight of far-infrared powder; 15 parts by weight of agent; 21 parts by weight of solvent.

[0145] The far-infrared powder is pyrrole-modified far-infrared powder.

[0146] The preparation method of the pyrrole-modified far-infrared powder is the same as that in Example 1.

[0147] The preparation method of the far-infrared heat-conducting paste is the same as in Example 1.

[0148] The resin binder A is polyamide resin, purchased from Anqing Hongyu Chemical Co., Ltd., the brand is HY-608; the resin binder B is epoxy resin, purchased from Wuxi Xinyehao Chemical Co., Ltd. , the grade is E-52 (618); the conductive filler is aluminum-doped zinc oxide powder, purchased from Shenzhen Jingcai Chemical Co., Ltd., and the model is AZO-W; the far-inf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com