Method for preparing viscosity-reducing polycarboxylate superplasticizer

A viscous polycarboxylic acid and water reducing agent technology, which is applied in the field of concrete admixtures, can solve problems such as the inability to effectively reduce the viscosity of concrete mixtures, and achieve the effects of controllable reaction rate, reduced production cost and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

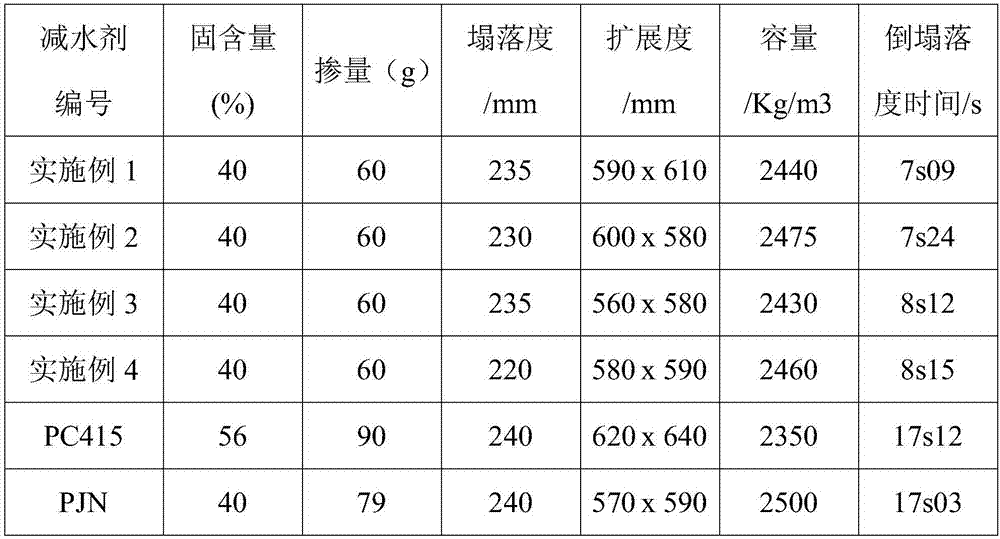

Examples

Embodiment 1

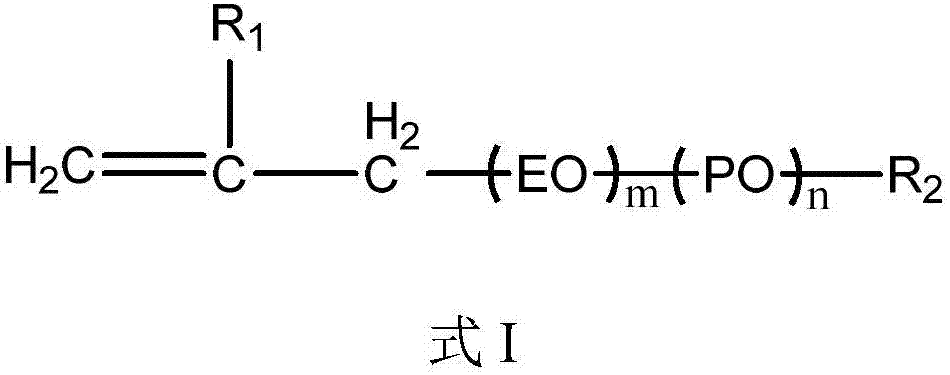

[0039] This embodiment provides a synthetic method of polycarboxylate water reducer, which specifically includes the following steps:

[0040] 1. Preparation of isopentenyl polyoxyethylene polyoxypropylene ether

[0041] (1) Add 85 g of prenol and 0.15 g of KOH into the reaction kettle, and replace the air in the kettle with nitrogen.

[0042] (2) When the temperature of the kettle rises to 100-110°C, start to feed 1650g of ethylene oxide and 350g of propylene oxide, keep the polymerization reaction temperature at 130°C, and the reaction pressure at 0.15Mpa. The reaction product of pentenyl polyoxyethylene polyoxypropylene ether.

[0043] (3) neutralize the above-mentioned reaction product, and then degas in the reactor to obtain m=15, n=20, isopentenyl polyoxyethylene polyoxypropylene ether with an average molecular weight of 1892.38.

[0044] 2. Preparation of polycarboxylate water reducer

[0045] (1) In a four-necked flask, add 200 g of isopentenyl polyoxyethylene polyo...

Embodiment 2

[0050] This embodiment provides a synthetic method of polycarboxylate water reducer, which specifically includes the following steps:

[0051] 1. Preparation of isobutylene-based polyoxyethylene polyoxypropylene ether

[0052] (1) Add 90 g of isobutenol and 0.20 g of KOH into the reaction kettle, and replace the air in the kettle with nitrogen.

[0053] (2) When the temperature of the kettle rises to 100°C, 1250g of ethylene oxide and 450g of propylene oxide are introduced into the reactor to keep the polymerization reaction temperature at 130°C and the reaction pressure at 0.20Mpa. The reaction product of oxyethylene polyoxypropylene ether.

[0054] (3) neutralize the above-mentioned reaction product, then degas in the reactor to obtain m=30, n=3, isobutenyl polyoxyethylene polyoxypropylene ether with an average molecular weight of 1551.8.

[0055] 2. Preparation of polycarboxylate water reducer

[0056] (1) In a four-necked flask, add 150 g of isobutylene polyoxyethylene ...

Embodiment 3

[0061] This embodiment provides a synthetic method of polycarboxylate water reducer, which specifically includes the following steps:

[0062] 1. Preparation of isopentenyl polyoxyethylene polyoxypropylene ether

[0063] (1) Add 100 g of prenol and 0.30 g of KOH into the reaction kettle, and replace the air in the kettle with nitrogen.

[0064] (2) When the temperature of the kettle rises to 100-110°C, start feeding 1395g of ethylene oxide and 1300g of propylene oxide, keep the polymerization reaction temperature at 100-110°C, and the reaction pressure at 0.35Mpa. After 3 hours of aging, the obtained Reaction product of isopentenyl polyoxyethylene polyoxypropylene ether.

[0065] (3) neutralize the above-mentioned reaction product, then degas in the reactor to obtain m=35, n=10, isopentenyl polyoxyethylene polyoxypropylene ether with an average molecular weight of 2192.62.

[0066] 2. Preparation of polycarboxylate water reducer

[0067] (1) In a four-necked flask, add 270 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com